6-35

WARNING

Many troubleshooting procedures present hazards that can result in severe personal inju-

ry or death. Only qualified service personnel with knowledge of fuels, electricity, and machinery haz-

ards should perform service procedures. Review safety precautions on page iii.

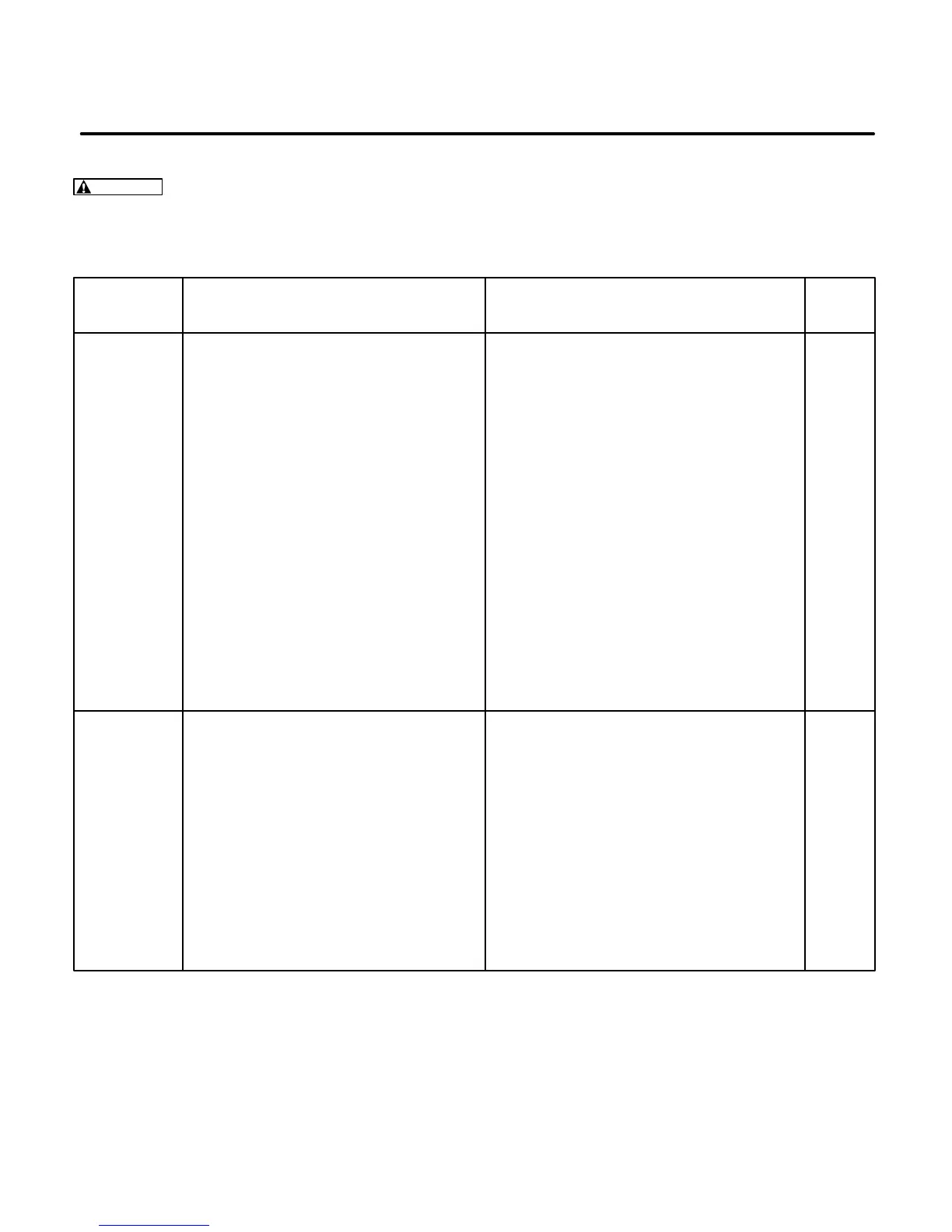

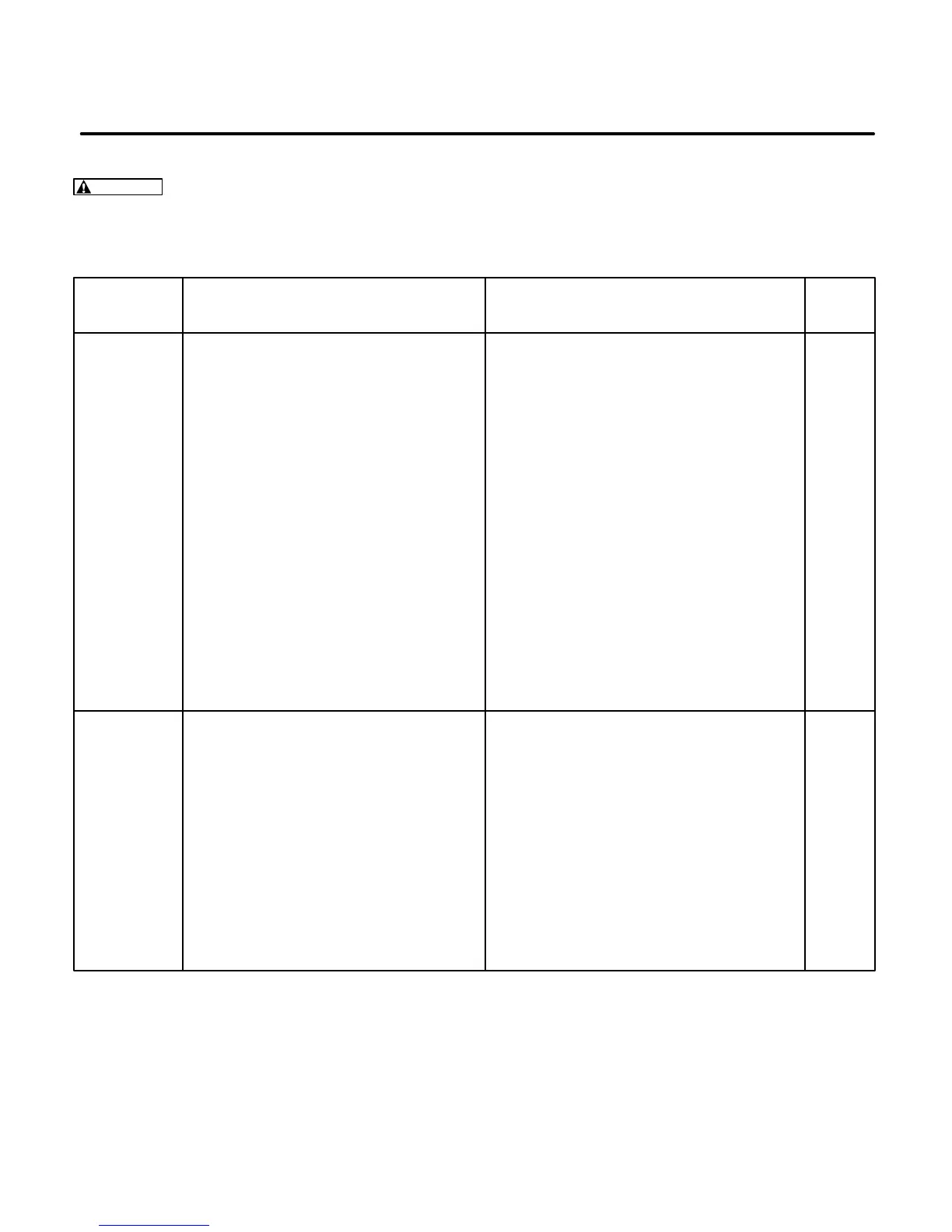

TABLE 6-18. TROUBLESHOOTING ENGINE PRIMARY SYSTEMS

Trouble Possible Cause Corrective Action Section/

Page

Engine Hunts 1. Fuel supply problem caused by: 1a. Check fuel pump and replace 8-19

or Surges a. Faulty fuel pump. if defective.

b. Contaminated fuel supply. 1b. Drain and refill fuel supply.

c. Vapor locking. 1c. Let genset cool down. Check for

blockage air inlet or outlet or improper

fuel system installation.

d. Plugged fuel filter. 1d. Replace fuel filter. 8-19

e. Carburetor passages plugged. 1e. Clean passages or replace pilot jet. 8-15

2. Incorrect fuel mixture due to: 2a. Adjust carburetor main and 8-13

a. Incorrectly adjusted idle adjustment screws.

fuel mixture screws. 2b. Disassemble carburetor and 8-14

b. Dirt or varnish in carburetor. clean all internal passages.

3. Governor problem due to: 3a. Check linkage alignment.Make sure 8-9

a. Sticking or binding governor linkage. it does not touch other parts. Clean

b. Incorrect governor adjustment. and lubricate linkage.

c. Faulty governor spring. 3b. Adjust speed and sensitivity settings. 8-9

d. Governor mechanism worn 3c. Replace governor spring.

excessively. 3d. See

Governor

in Section

10.

Engine

10-8

Block Assembly

.

High Oil 1. Oil viscosity too light or oil is diluted. 1. Drain oil and refill with correct

Consumption viscosity oil.

(Note: New 2. Crankcase breather valve is 2. Clean crankcase breather 8-8

engines can dirty, faulty or improperly installed. and replace if defective.

have high

oil consump- 3. Oil leaks. 3. Locate source of leak and

tion during repair as required.

break-in)

4. Excessive engine wear. 4. See Section

10.

Engine Block Assembly

.

5. Light loading. 5. Do not run genset at no-load for long

periods of time.

6. Intake valve seal worn or defective. 6. Replace intake valve seal. 10-7

Loading...

Loading...