Faults

- 39 -

optek-Manual--1004-1022-02--156-US-2017-12-11

www.optek.com

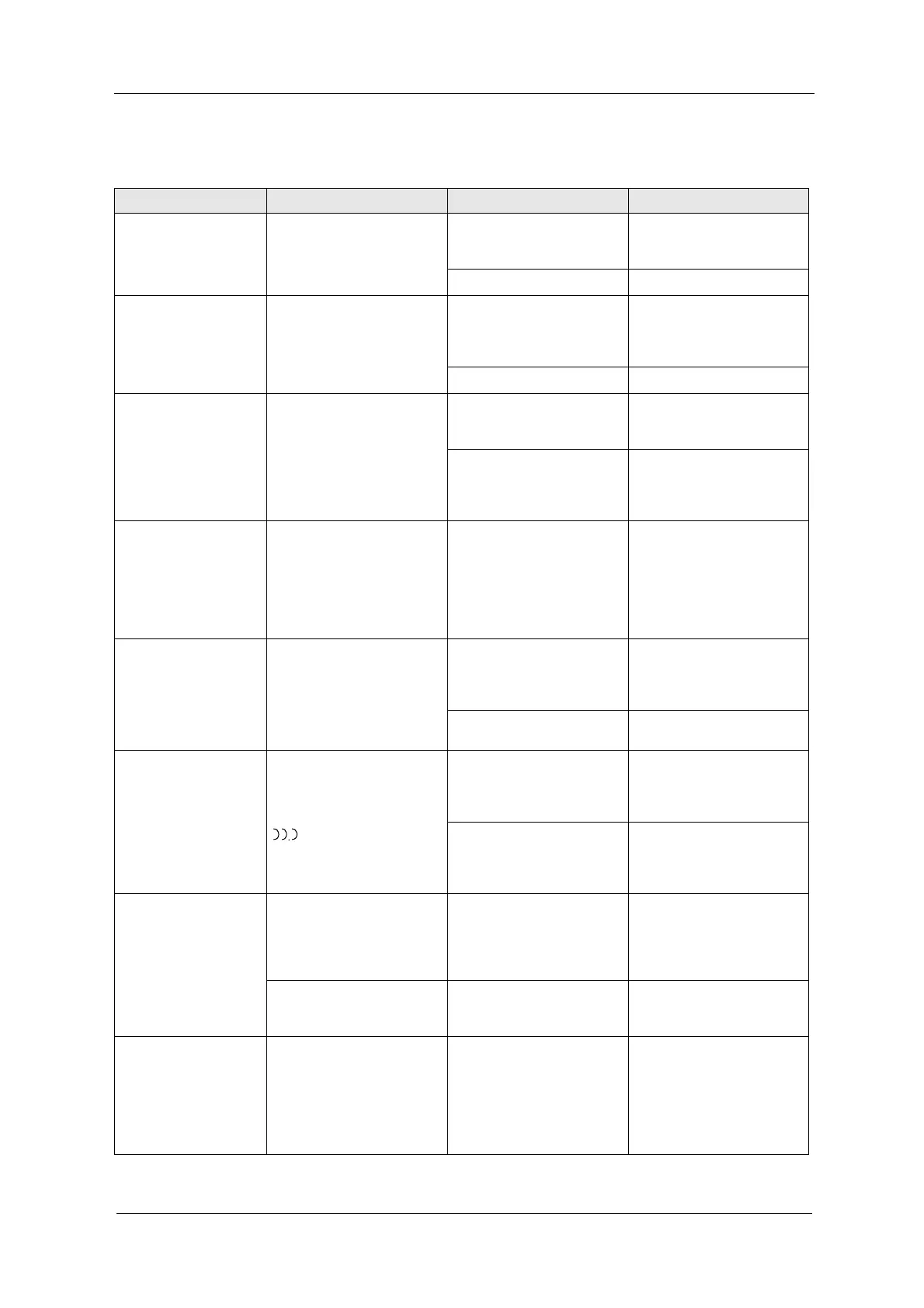

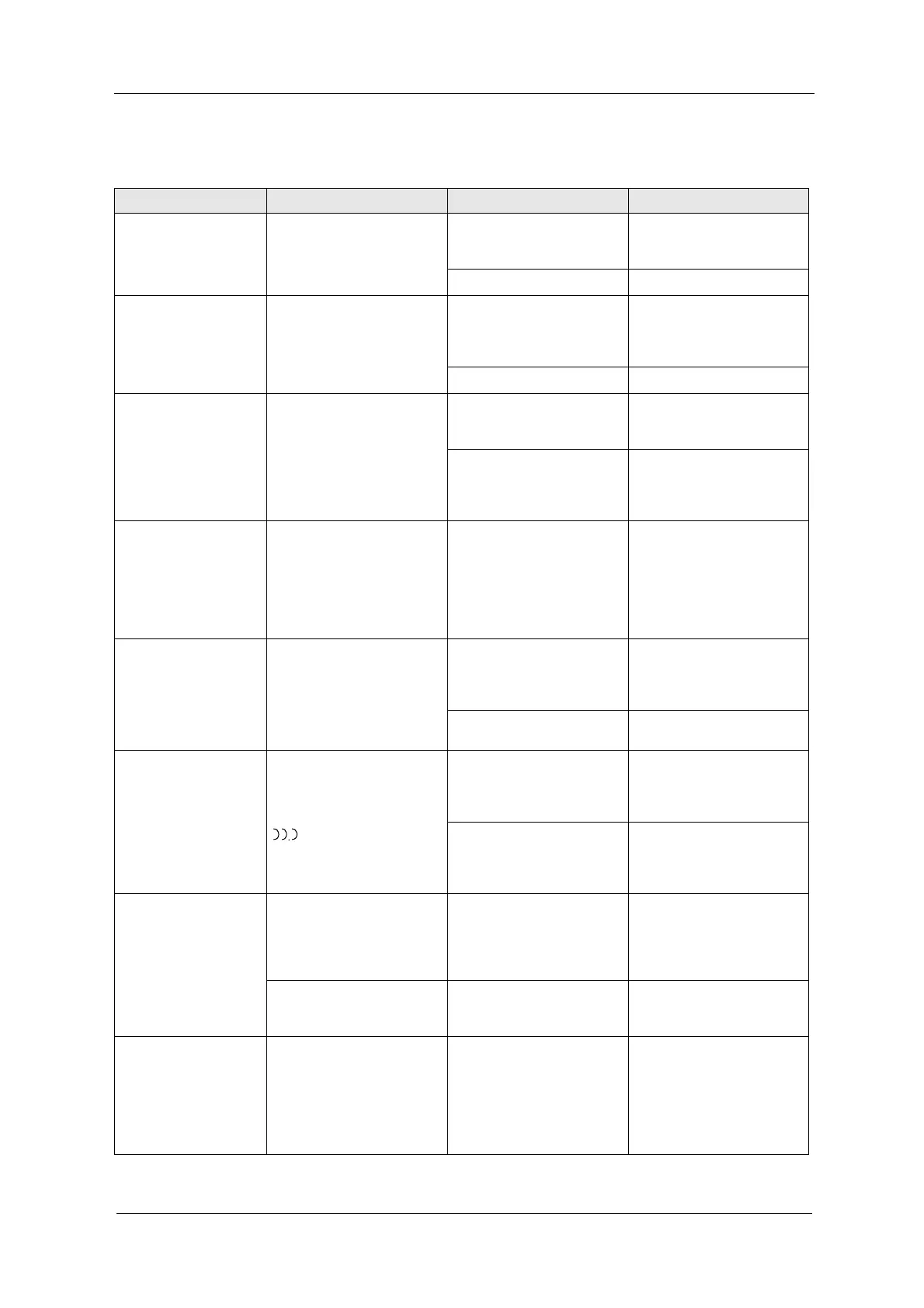

Tab. 7 Possible faults and remedies

Possible fault Possible remarks Cause Remedy

Failure of lamp module

• "Lamp failure" LED of

converter flashes.

• Signal loss

Lamp cable between sensor

and converter defective

• Continuity test of lamp cable

• Exchange lamp cable for new

one.

Lamp module defective • Exchange lamp module.

Detector failure -

Detector cable between sen-

sor and converter defective

• Continuity test of detector

cable

• Exchange detector cable for

new one.

Detector defective • Exchange detector.

Condensate formation

Unrealistic, random measuring

results

Humidity gets into optical

housing and forms condensa-

tion deposits on windows.

• Use air purge

O-Ring missing or defective

• Disassemble sensor

assemblies and check

O-Rings, exchange if

necessary.

Wrong results

• Results are fluctuating.

• Zero point is drifting.

• Sensor body windows are

dirty.

• Sensor body windows are

corroded.

• Lamp module near failure,

lamp module near the end of

its life.

• Clean sensor body window.

• Exchange sensor body

window for sapphire window.

• Exchange lamp module.

Connection error

• No function

• No "Lamp failure" LED

message

Detector cable between sen-

sor and converter defective

• Continuity test of detector

cable

• Exchange detector cable for

new one.

Sensor cable incorrectly

connected to converter

• Check and revise

connections.

Measuring range excee-

ded

Converter indicates flashing

Process conditions

• Amplify measuring range.

• If the measuring range cannot

be amplified, reduce optical

path length.

Wavelength-dependent detec-

tor module reduces the dyna-

mic measuring range, optical

filters reduce wanted signal.

• Reduce optical path length

and / or change measuring

wavelength.

• Exchange lamp modul.

mA-signal (output)

The mA-output provides

correct current values when

measuring results are low and

too low current values when

measuring results are high.

Connected load > 500 ohms

• Check resistance of wiring.

• Use appropriate mA-input.

Small deviations given in %

Poor calibration of the receiving

mA-input

• Compensation by adjusting

calibration of the sending

mA-output.

Converter defective

None of the above mentioned

errors can be detected.

-

• Send system (converter and

sensor) to optek for checking

purposes. If necessary, the

sensor body can remain in

the pipeline so that only the

optical arms and the

converter have to be sent.

Loading...

Loading...