Version 1.2.8 - 2020-08-03 35Translation of original operating manual

MT50 GB

MT50_GB_4.fm

INFORMATION

High temperatures are generated at the tip of the tool by the occurring friction heat. The tool

should be cooled during the milling process. Cooling the tool with a suitable cooling lubricant

ensures better working results and a longer edge life of the cutting tool.

INFORMATION

Use a water-soluble and non-pollutant emulsion as a cooling agent. This can be acquired from

authorised distributors.

Make sure that the cooling agent is properly retrieved. Respect the environment when dispos-

ing of any lubricants and coolants. Follow the manufacturer’s disposal instructions.

5.8 Manual spindle sleeve feed

5.8.1 Rough adjustment

Actuate the quill lever in order to manually lift respectively lower the quill.

You can set the spindle sleeve to a given height using the tightening lever.

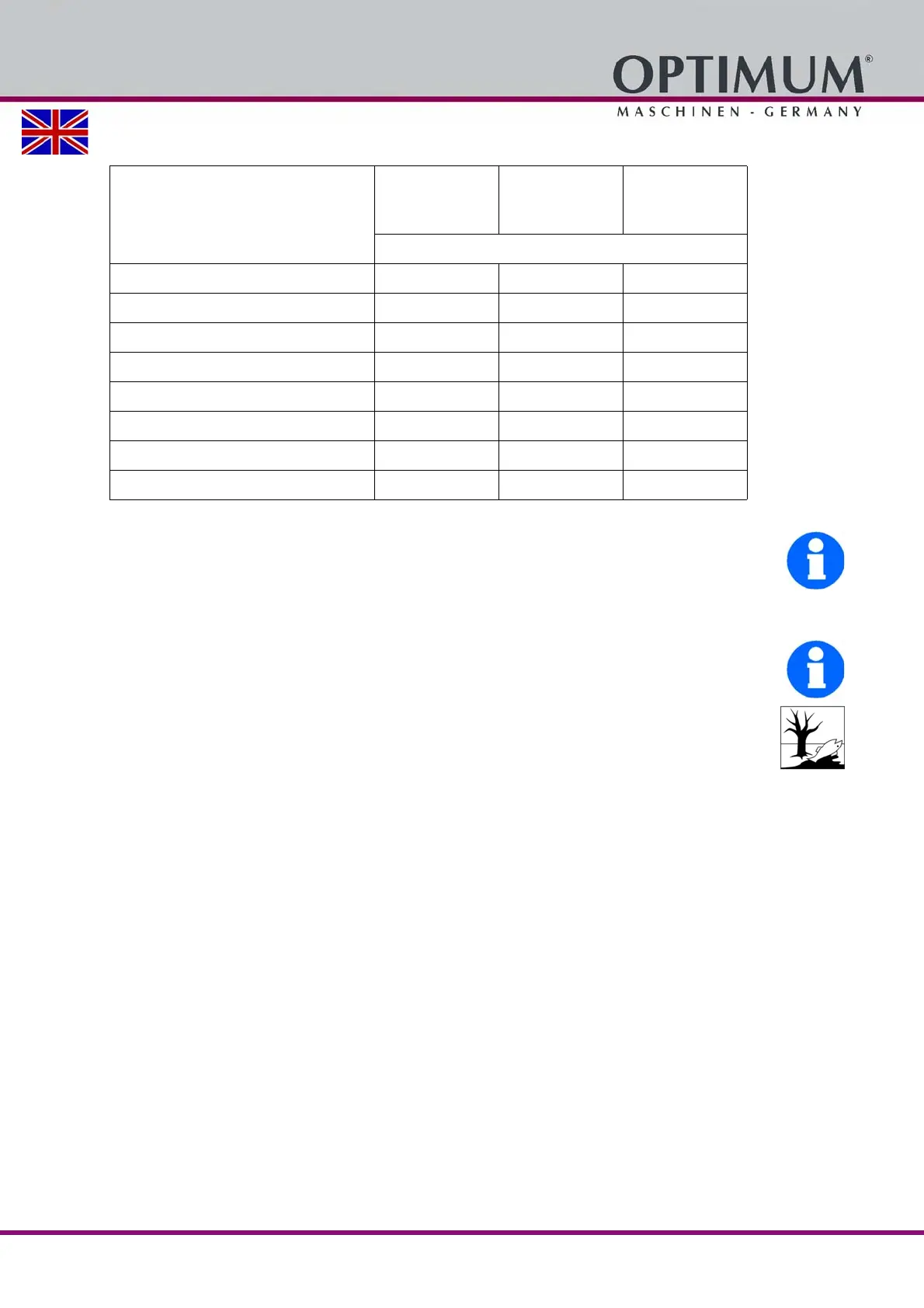

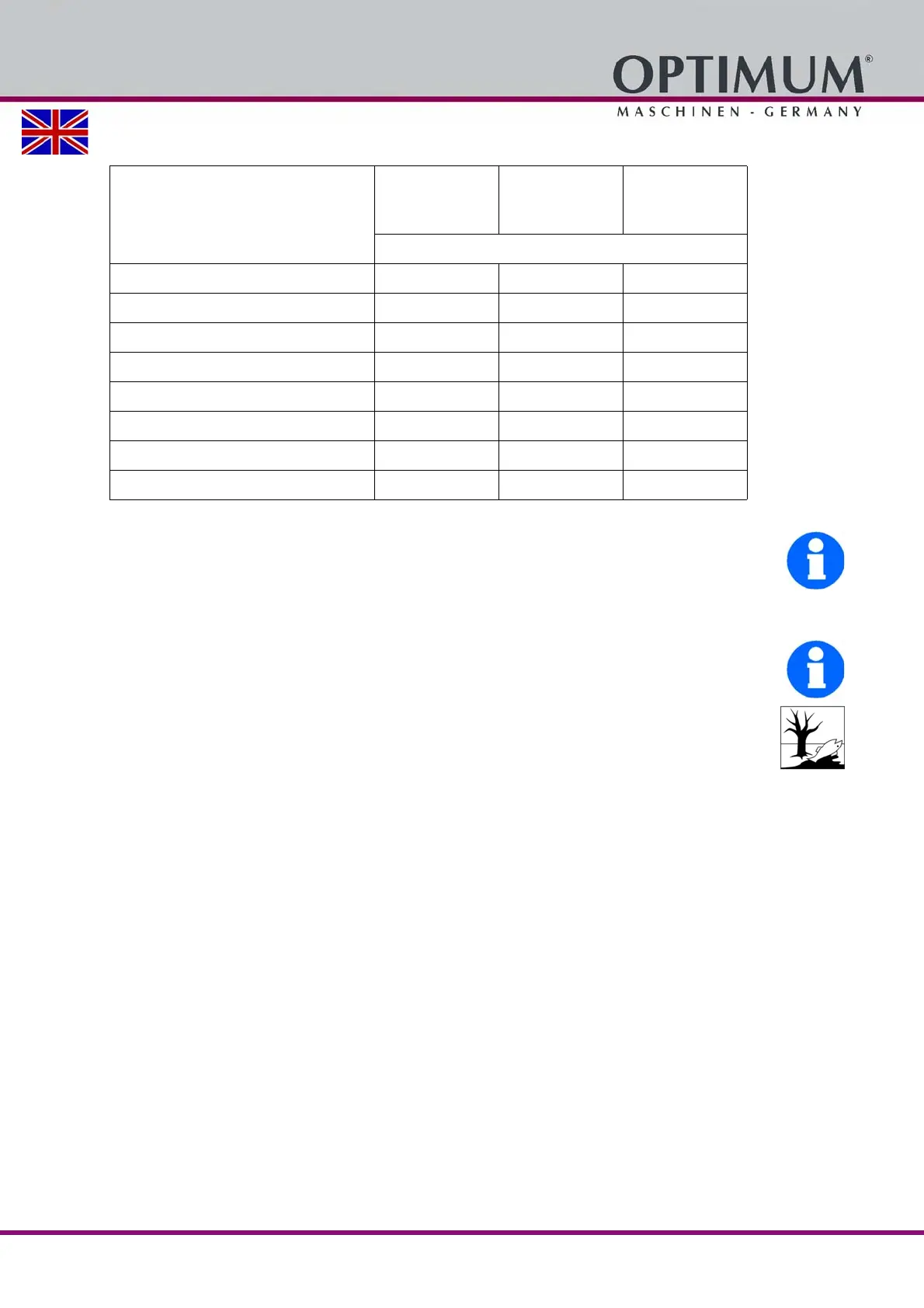

Tool diameter

[ mm ]

form cutters

Steel

15 - 24 m/min

Grey cast iron

10 - 20 m/min

Cured Al alloy

150 - 250

m/min

Speed [ min

-1

]

4 1194 - 1911 796 - 1592 11937 - 19894

5 955 - 1529 637 - 1274 9549 - 15916

6 796 - 1274 531 - 1062 7958 - 13263

8 597 - 955 398 - 796 5968 - 9947

10 478 - 764 318 - 637 4775 - 7958

12 398 - 637 265 - 531 3979 - 6631

14 341 - 546 227 - 455 3410 - 5684

16 299 - 478 199 - 398 2984 - 4974

Loading...

Loading...