Version 1.2.8 - 2020-08-0348 Translation of original operating manual

MT50

GB

MT50_GB_5.fm

6.3 Inspection and maintenance

The type and level of wear depends to a large extent on the individual usage and operating

conditions. For this reason, all the intervals are only valid for the intended operating conditions.

Interval Where? What? How?

Start of work,

after every

maintenance or

repair work

Milling-machine

Safety check on page 15

Start of work,

after every

maintenance or

repair work

Mobile machine parts

Oiling

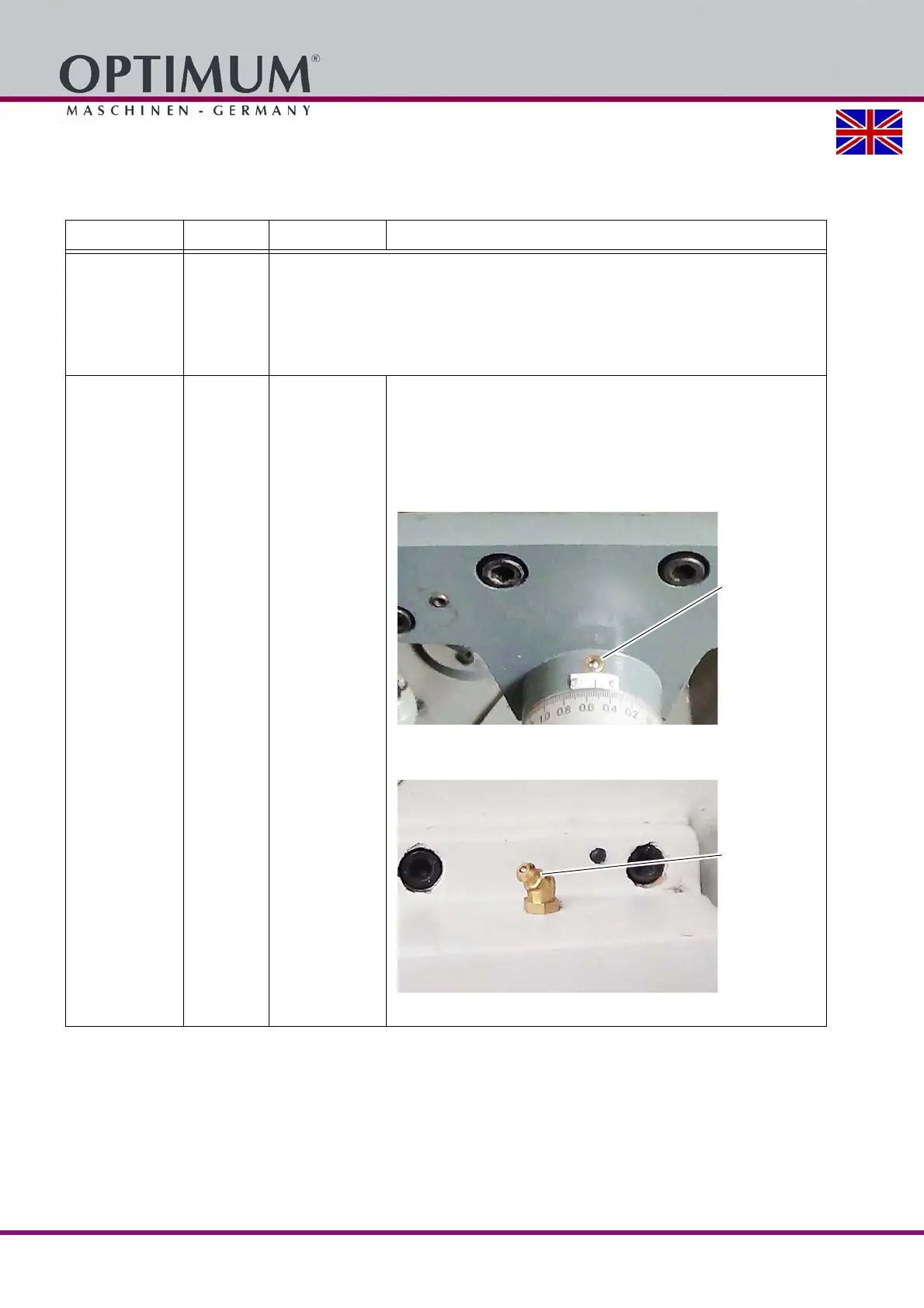

All mobile machine parts such as guides, feed screws,

spindle nuts must be oiled in regular intervals.

Always slightly oil bare surfaces.

Lubricate lifting spindle of the cross table using ball bear-

ing grease.

Oil at these lubricating point positions.

Img.6-1: Oiler cup

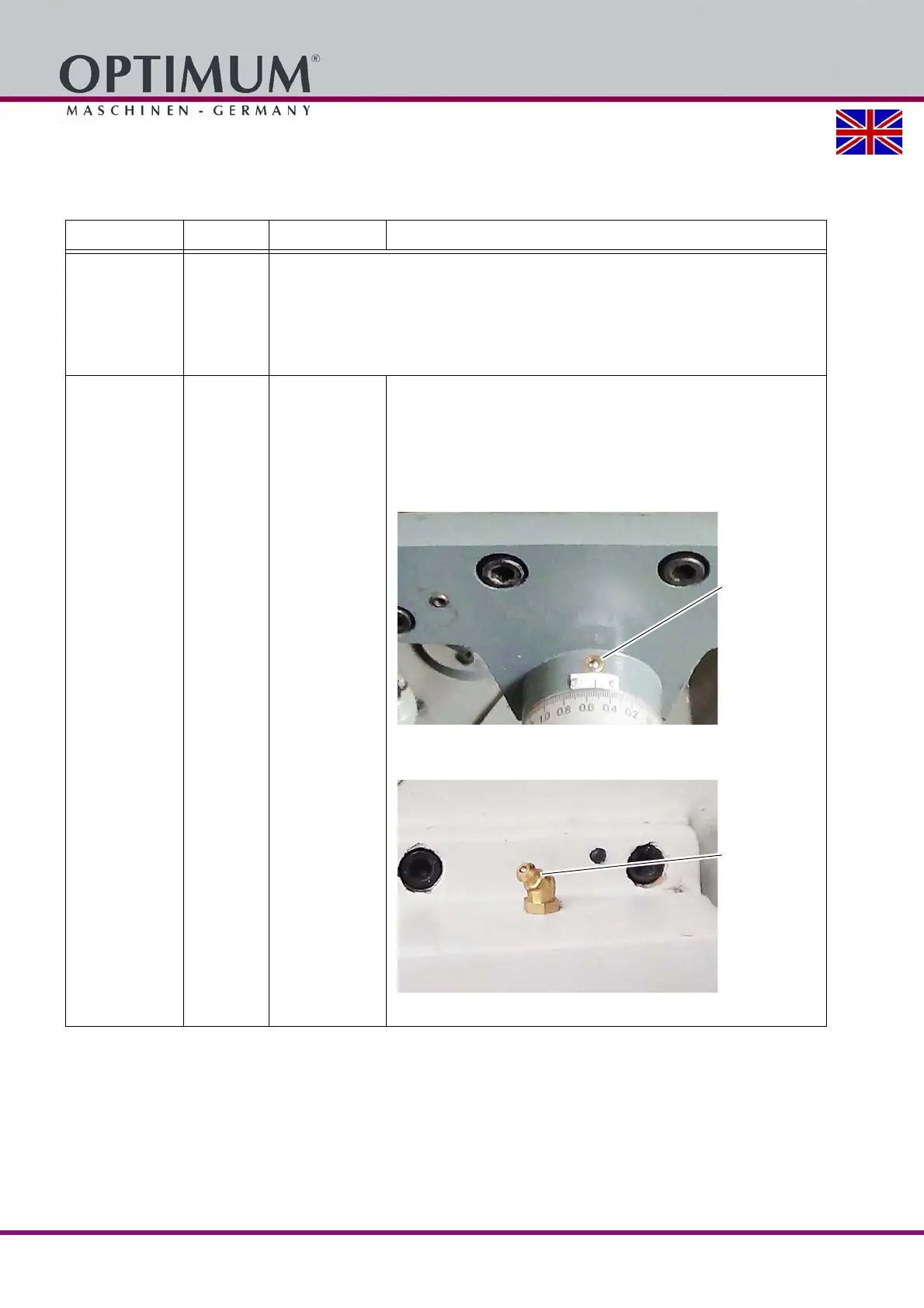

Lubricate at these lubricating point positions.

Img.6-2: Lubricating nipple

Loading...

Loading...