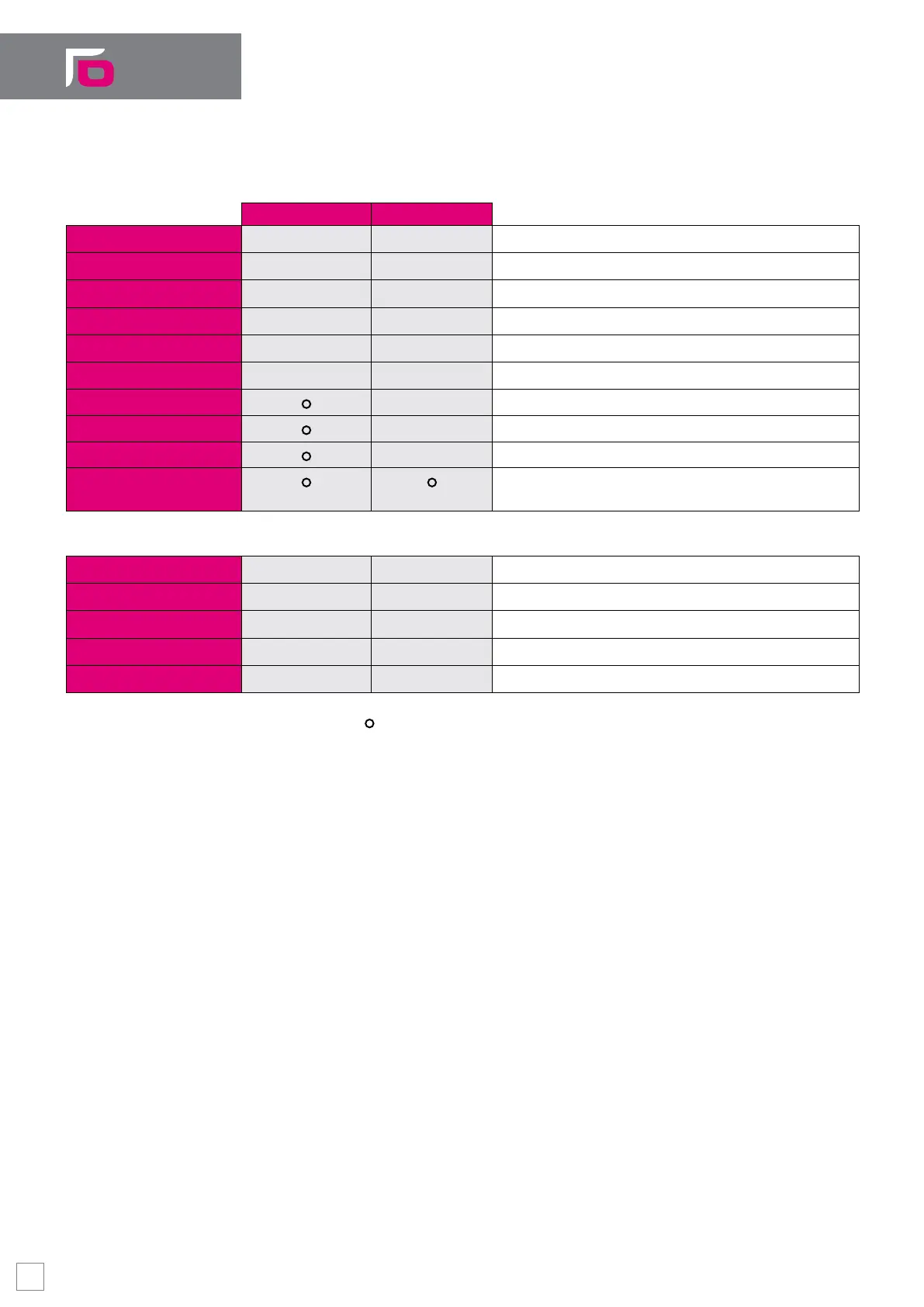

WinNBI consists of different applications, each one with specic functionality:

End User toolkit Windows desktop Windows CE

BootController

● ●

CNC boot manager

ProcessController

● ●

CNC main and auxiliary screens manager and builder

SystemHistory

● ●

System journal

TableEditor

● ●

Table data manager (Offset, Tool, Origins…)

MachinePlot

●

- 2D/3D graphical drawing of the tool trajectory

FileBrowser

● ●

File manager (for CNC and PC)

PathView/ISOView

- Graphical tool for Part Program preview and management

DigiCAD

- 3D graphical tool for digitizing with Spline

OPENCut

- CAM for Plasma & Laser Cutting

OPENMill

Conversational 2D programming and mini-CAM for

milling/drilling machines

OEM toolkit

ODM

●

- System congurator and run-time calibration

Security

●

- SW Installation, backup, restore. License manager

Calibration Tool

● ●

I/O mapping tool for an easy conguration of the I/O

TimeMonitor

●

- PLC and System task timing graphical monitor

O-Scope

●

- Oscilloscope to trace many system parameters

● Available Option - Not available

Process Controller

The application Process Controller, designed to display all the most important information

of the machine tool and to interact with the end-user, allows full customization of the

operator interface in a multi-screen environment using the Layout Builder tool.

Layout Builder offers a wide range of graphical “objects” to create custom screens using

only the mouse with a “Point & Click” and “Drag & Drop” approach, with no need of any

knowledge of programming languages. The single screen can be selected and activated

automatically (as and when events occur) or manually (by toggling real or virtual

buttons). Among the various objects available, there are programmable push buttons,

directly interfaced with CNC functions or managed by the machine logic, the display

and animation of graphic bitmap-objects, progress bars, data entry elds as well as CNC

messages, and variable displays and editing of variable values.

8

Loading...

Loading...