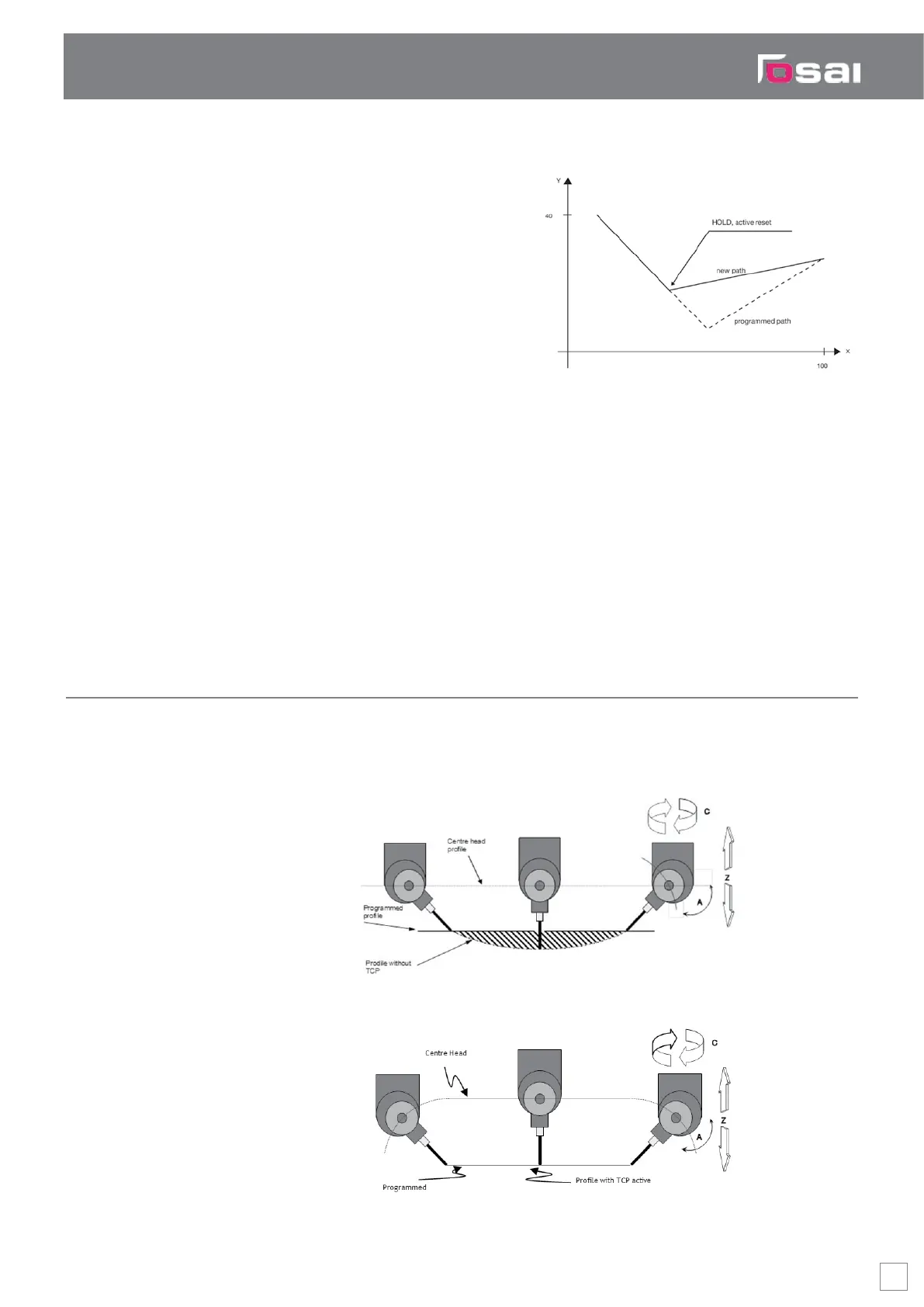

Active Reset

This feature allows a program block

that is currently in execution to

be cancelled and to automatically

adjust the prole in order to resume

execution from the subsequent block.

Active reset is enabled by the machine

logic and the part program.

Active Reset

Part Program execution time estimation

In order to estimate the machining cost, OPENcontrol can rapidly simulate the whole Part

Program. When simulation is done, information provided are:

Total execution time of the program

Working times (operations made with G1/G2/G3...)

Positioning times (times in G0/G10)

Technology execution times (times of the functions M, S, T)

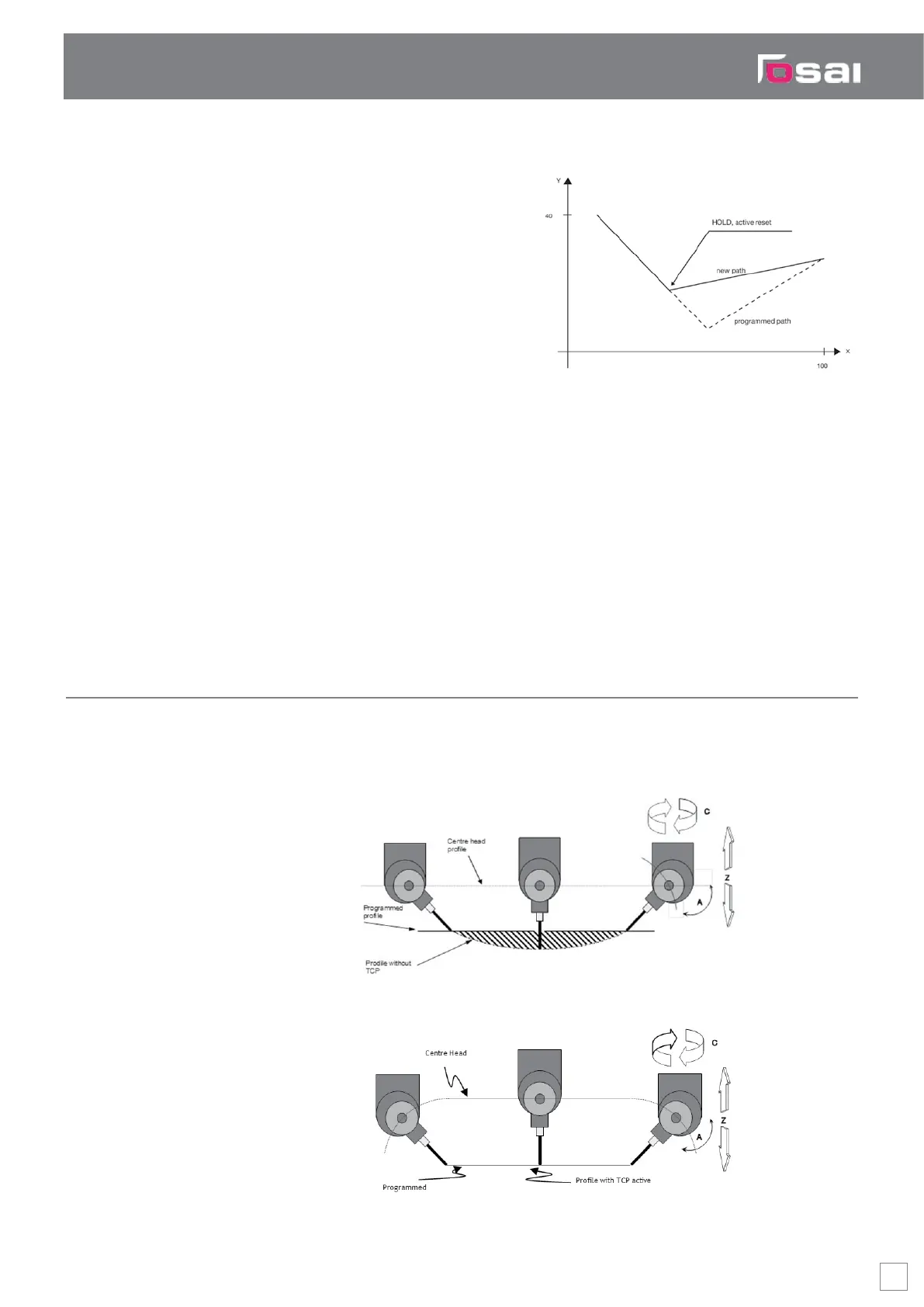

Tool Centre Point (TCP)

The functionality of Tool Centre Point, greatly simplies the programming of the 5 axes

machines (3D) by automatically managing the movement of the axes to keep the tool tip

in the programmed position taking care of the machine kinematic.

Programming without TCP

Programming with TCP

OPENcontrol Technical overview

21

Loading...

Loading...