High Speed Machining

With OPENcontrol, new Interpolation algorithms have been developed to respond to the

increasing requirement for machining cycles with high speeds and high quality surface

nishing, particularly on 5 axes machines.

The High Speed Machining (HSM) can be activated when one of the available Tool Center

Point kinematics is enabled (TCP programmed). While TCP calculates axes position

considering the trajectory of the tool tip only, HSM add the calculation, of the prole and

relevant acceleration/velocity of the joints (single axis) using the inverted kinematics

calculation to allow to use the maximum dynamic and precision of the axes maintaining

the programmed feed on the workpiece.

The algorithm allows to reach the best machine performances and machining results

avoiding to stress the mechanics.

Virtualization

Virtualization means a set of features for programming virtual axes on a plane to obtain

the motion of the associated physical axes in a three dimensional space.

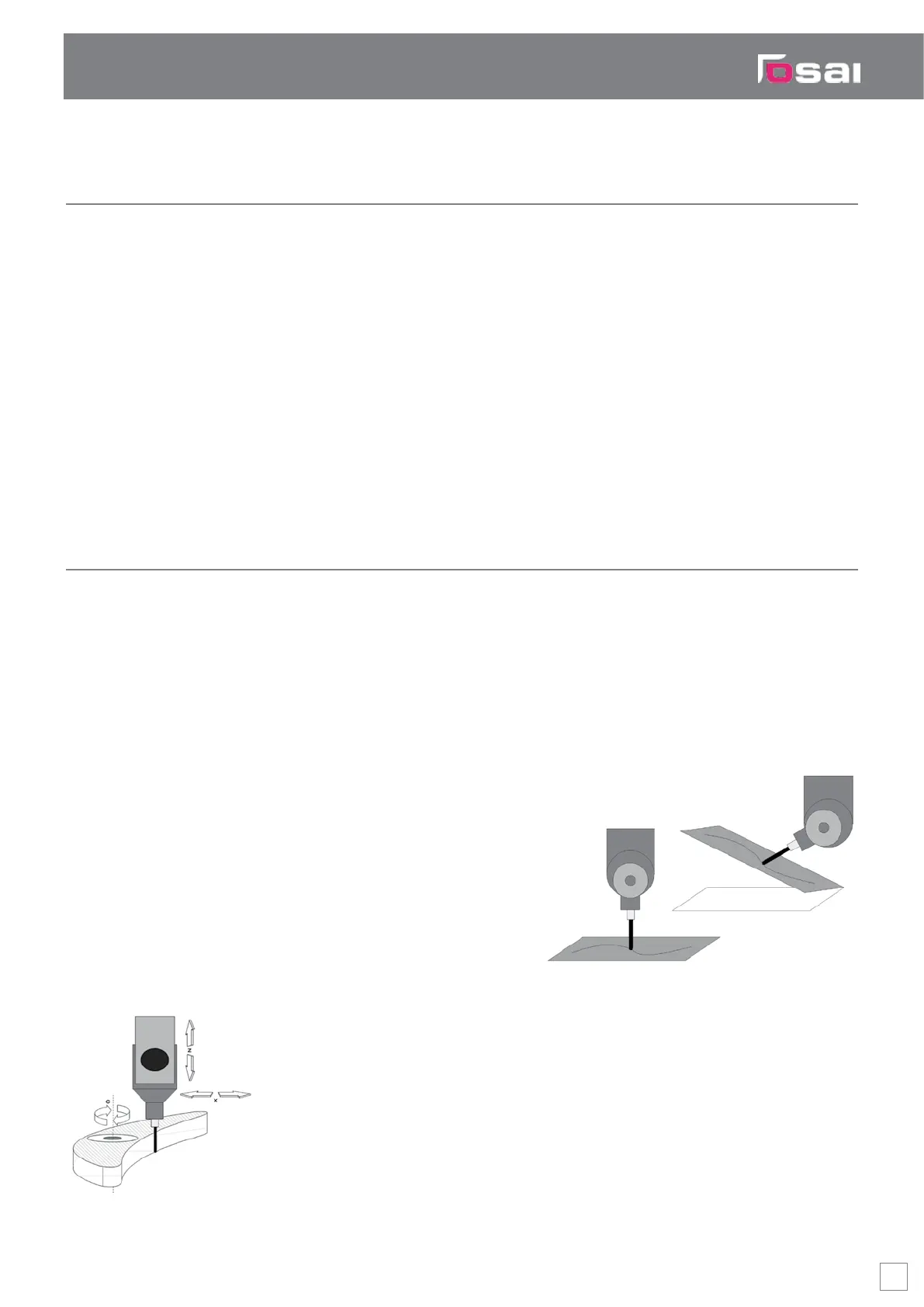

Programming on Rotated Plane

This virtualization allows the programming of any function of the machine (linear or

circular interpolation, canned cycles, probing cycles, cutter radius compensation, TCP,

etc.) in a space rotated towards the 3 Cartesian axes of the machine tool.

It is activated by the program through

an instruction (UPR) where the rotation

angles are specied.

The same axis names used for the original

plane are used to program the virtual

plane. It is also possible to temporarily

switch to the programming of the original

plane using the function G79.

Machining on a 3D oriented plane

Polar Coordinates

Polar coordinates are used when a linear X axis and a rotary C axis must be moved

by programming the axes positions on the UV Cartesian plane. Polar programmed

positions are automatically translated into the physical axes position. This function

is enabled with the UVP (Use Virtual Polar) instruction.

Machining with polar coordinates

OPENcontrol Technical overview

23

Loading...

Loading...