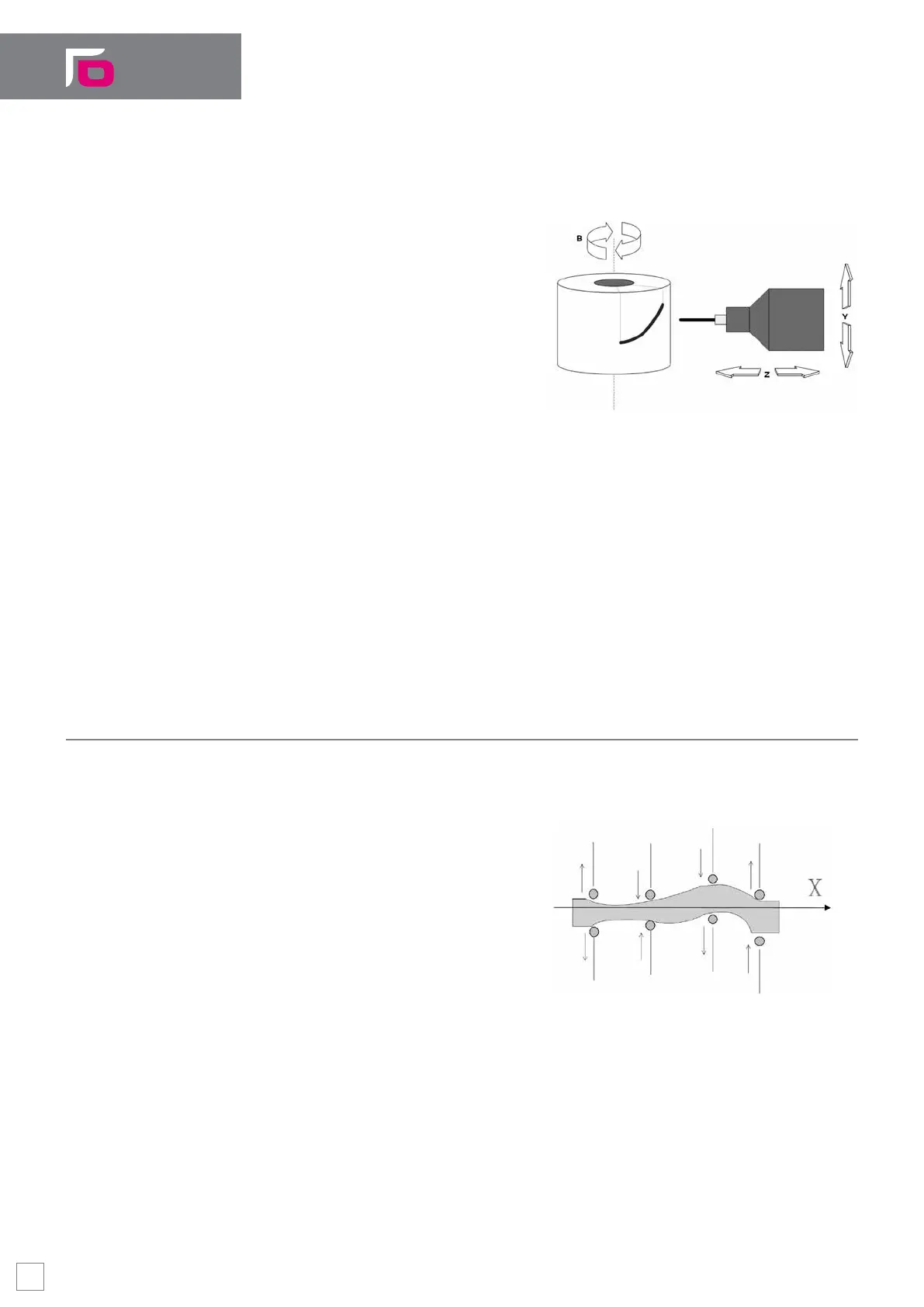

Cylindrical Coordinates

This feature is used when a linear X axis and

a rotary B axis are moved by programming

the axes positions on a Cartesian (e.g.

WX) plane. Virtual X axis movements are

the same as X physical axis movements,

whereas every virtual W axis movement

corresponds to an arc that -depending on

the cylinder radius is translated into an

angular movement of the physical B axis.

This function is enabled by the UVC (Use

Virtual Cylindrical) code.

Machining with cylindrical coordinates

Non-orthogonal axes

The UVA (Use Virtual Angular) command makes it possible to program non-orthogonal

axes by treating them as if they were orthogonal.

This type of virtualization is used when moving two linear XY axes that are not mutually

orthogonal, by programming the coordinates on a virtual orthogonal (e.g. UV) plane. The

U axis, the abscissa of the new pair of axes, will be coaxial with axis X, whereas axis V

will be perpendicular to U, forming an angle of 90°.

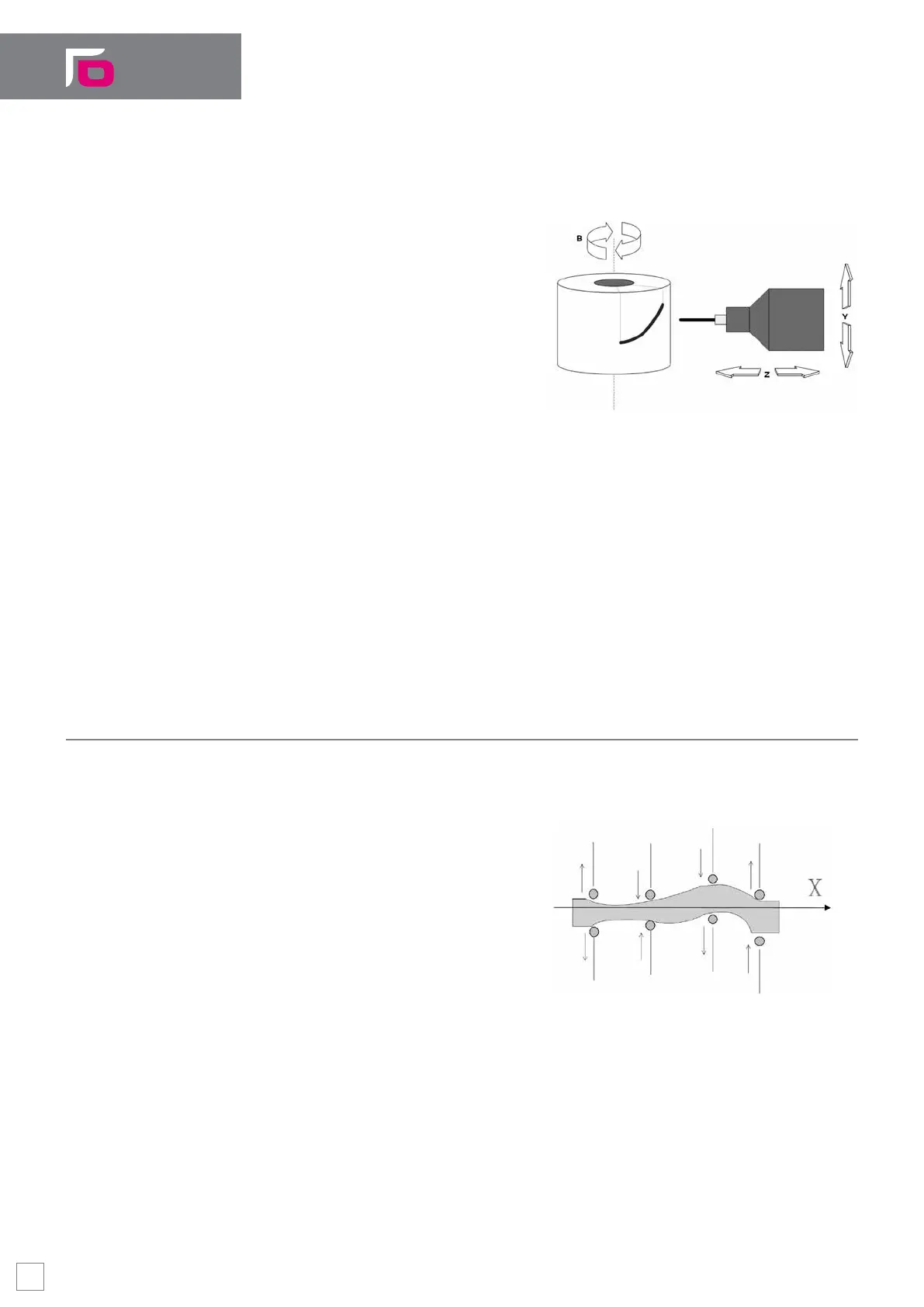

Multi-Axis Electronic Cam

This option allows a group of slave axes to be moved along a specic path, depending

on the position of a master. While the master moves, the system moves the slaves (for

example, N heads carrying different

tools), which simultaneously follow a

trajectory but independent of each other.

In addition to the positions, the electronic

cam controls with accuracy the speed of

movement of the slave axes by adapting

it to the movement of the master axis,

thereby ensuring that the system covers

the required prole in optimal conditions.

Example of machining with one master (X) and eight slaves

The relationship between the positions of the master axis and the slave one, can be

created off-line by a CAD or through graphical applications. Advanced PEG (Position

Event Generator) functionalities simplify the application development permitting to

synchronize output signals with the master axis positions while the exibility of the

system is guaranteed by many other features like:

Cams managed by Part Program and PLC

Cams dynamic definition (up to 64)

Software Key Features

24

Loading...

Loading...