Simultaneous activations of the same Cam with different rules

Start and stop driven by input signals or other axis positions (by PLC)

Cam based on virtual master axis (by PLC)

Rollover Cam

Cam of cam (where the slave is a master of another cam)

Volumetric and Cross Compensation, Axis Calibration

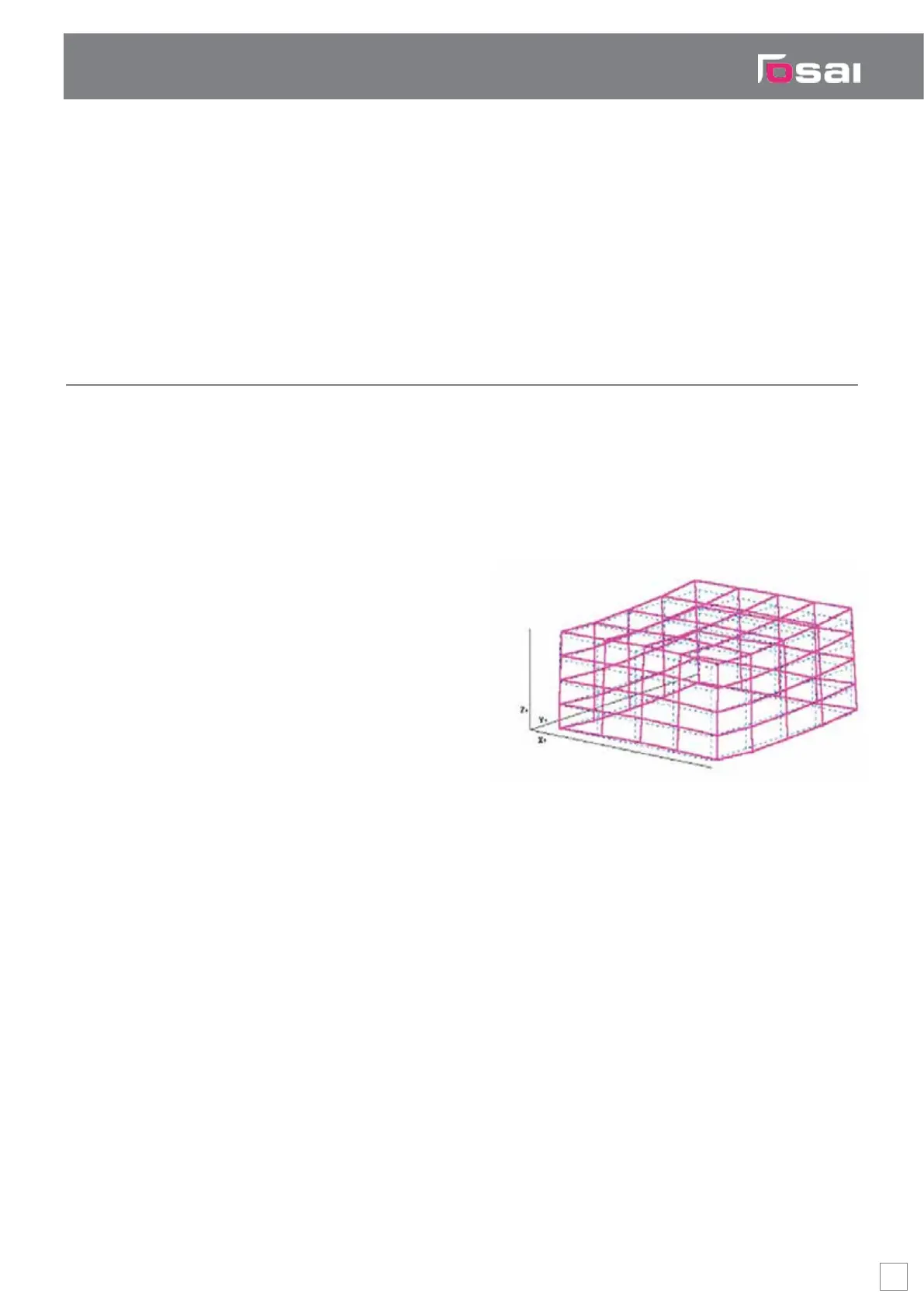

OPENcontrol CNC can offer even higher working precision for the machine tool, using

the Volumetric Compensation algorithm. This algorithm has been designed to take into

account and correct for any positioning errors, which occur as a result of any mechanical

distortions created by the machine tool in the working volume.

The OPENcontrol Volumetric Compensation algorithm is capable of correcting many

different types of positioning errors in space.

Acquired positioning error data

can be used to correct a single or

multiple errors introduced by the

mechanics. Typical uses would be

bi-directional Axis Calibration,

twist error correction and Cross

Compensation of an axis, non-

orthogonal, etc.

After taking a number of

measurements on the machine

tool, OPENcontrol is able to

compensate the errors by interpolating the available values.

The number of measurements taken will determine the accuracy of the correction which

can be achieved. The greater the number of samples is, the greater will be the accuracy.

This software module is organized with three different optional levels:

Level 1: bi-directional Axis Calibration for a single axis

Level 2: Cross Compensation and compensation of non-orthogonal axes

Level 3: Compensation of all position error types

Higher levels include the features of the previous ones.

OPENcontrol Technical overview

25

Loading...

Loading...