The algorithms take into account several

factors:

Maximum speed change allowed on

each axis

Jerk of each axis in the transition

from linear to circular blocks (linear/

circular, circular/linear, circular/

circular) in the case of tangent blocks

Forecasting and control of the radius

of curvature of the profile

Control of the shape error when the

filters are active

Axes motion lters (FLT)

In order to increase speed on the prole and to reduce machine mechanical vibrations,

with OPENcontrol it is also possible, through the FLT command (accordingly with velocity

leap axes parameter), to congure and to enable lters acting on the geometry and on

the dynamics of axis movements. With this type of lters, it is possible to average all the

points and speeds transmitted to the servo ampliers. This feature makes it possible to

improve dynamic behaviour on the electromechanical system when a program composed

by a series of small axis steps is executed.

Velocity and Acceleration Feed Forward (VFF and AFF)

The VFF and AFF, that can be dynamically enabled and disabled, are managed by the servo-

loop, according with the servo-drive, and allow the acceleration and the speed to be strongly

controlled, as well as the position, to reduce the following error to virtually zero. The result is

the complete control of the axes for a great surface nishing of the machined part.

Tangential axis control (AXT)

The tangential control enables the automatic control of a rotary axis. The axis is rotated

to maintain constant orientation towards the prole. Specically designed for stone

machining, it is often used to automatically maintain a saw or diamond wheels tangential

to the prole.

Constant or Variable Pitch, Multi-start, Threading (G33)

OPENcontrol has cylindrical, taper, or face threading cycles with constant or variable

pitch. The threading motion is synchronized with spindle rotation.

The R parameter in a G33 block enables multi-start threading, starting the motion of

the axes from an angular position that varies according to the programmed R value.

This permits easy programming of the threads, always starting from the same linear axis

position.

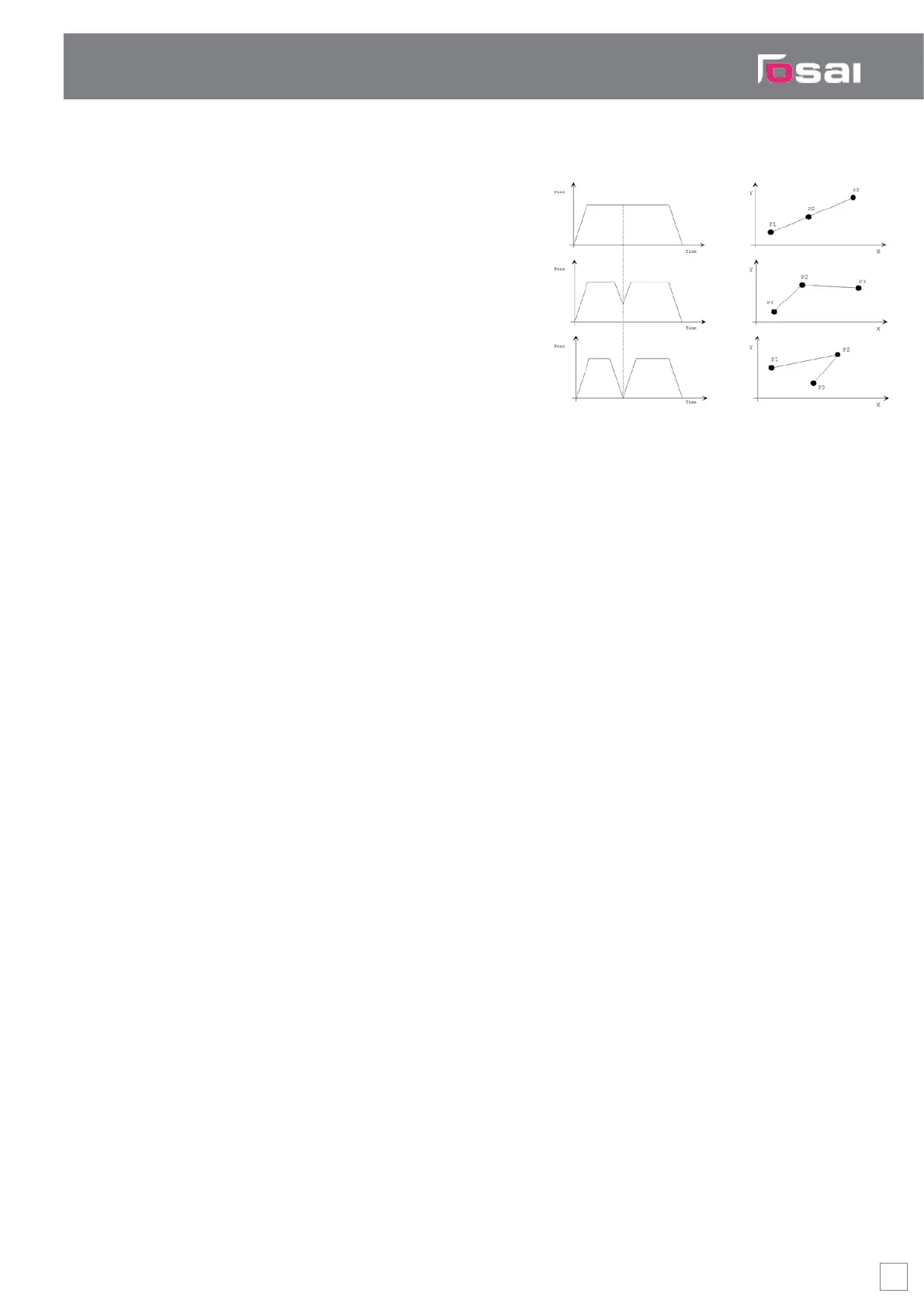

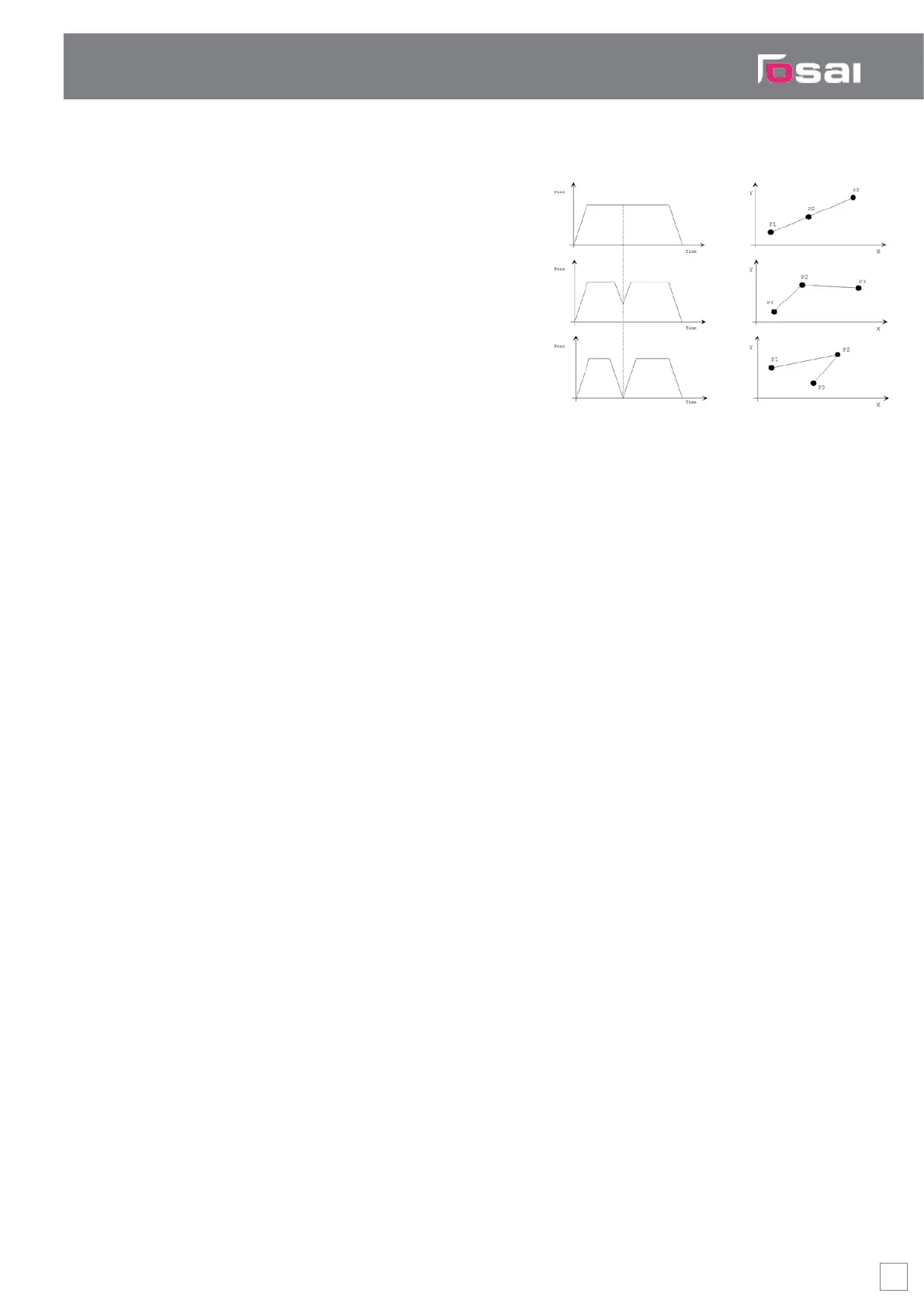

Feedrate diagram in continuous mode

(G27) with Look Ahead enabled

OPENcontrol Technical overview

19

Loading...

Loading...