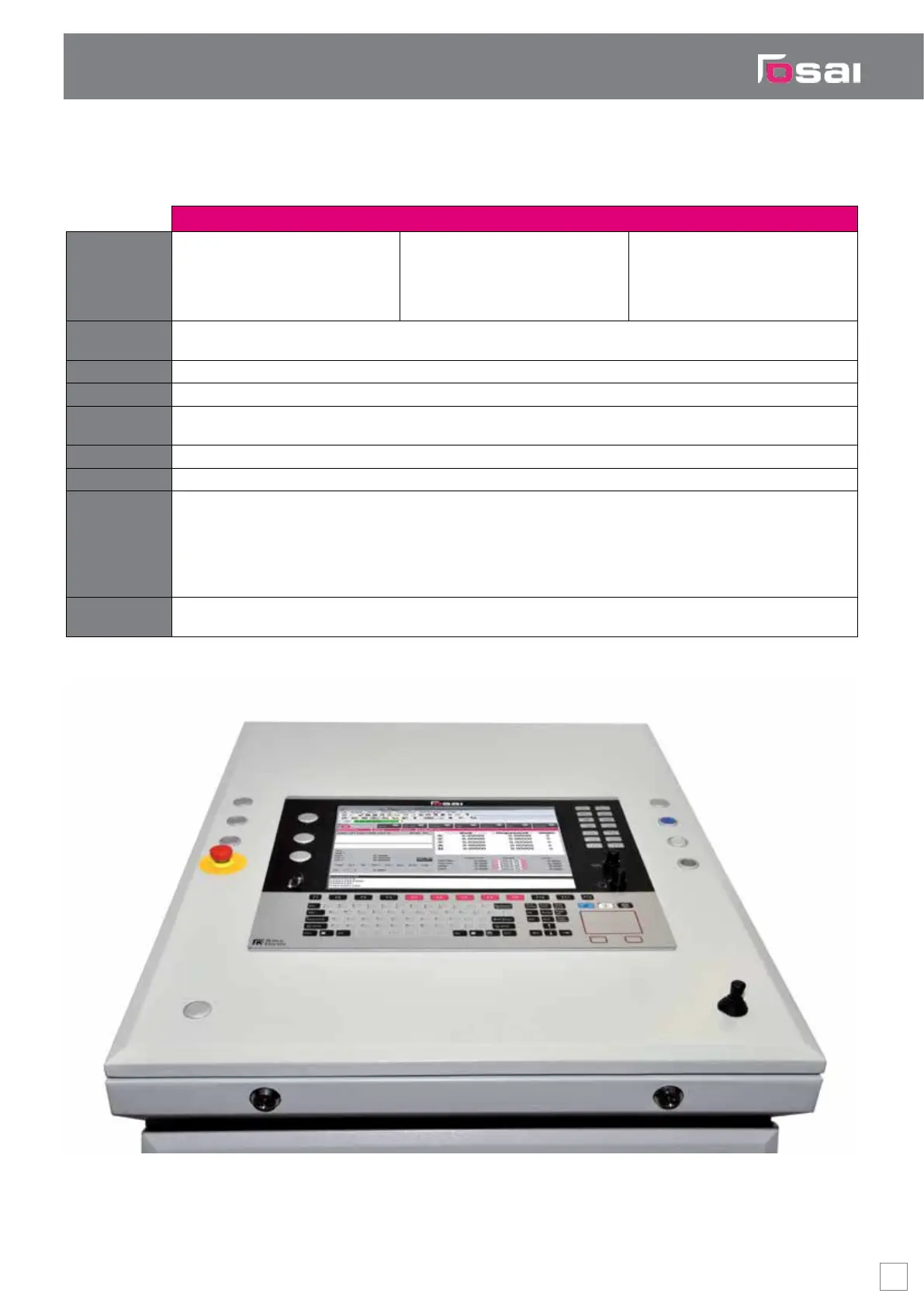

Technical Data

Turnkey Conguration

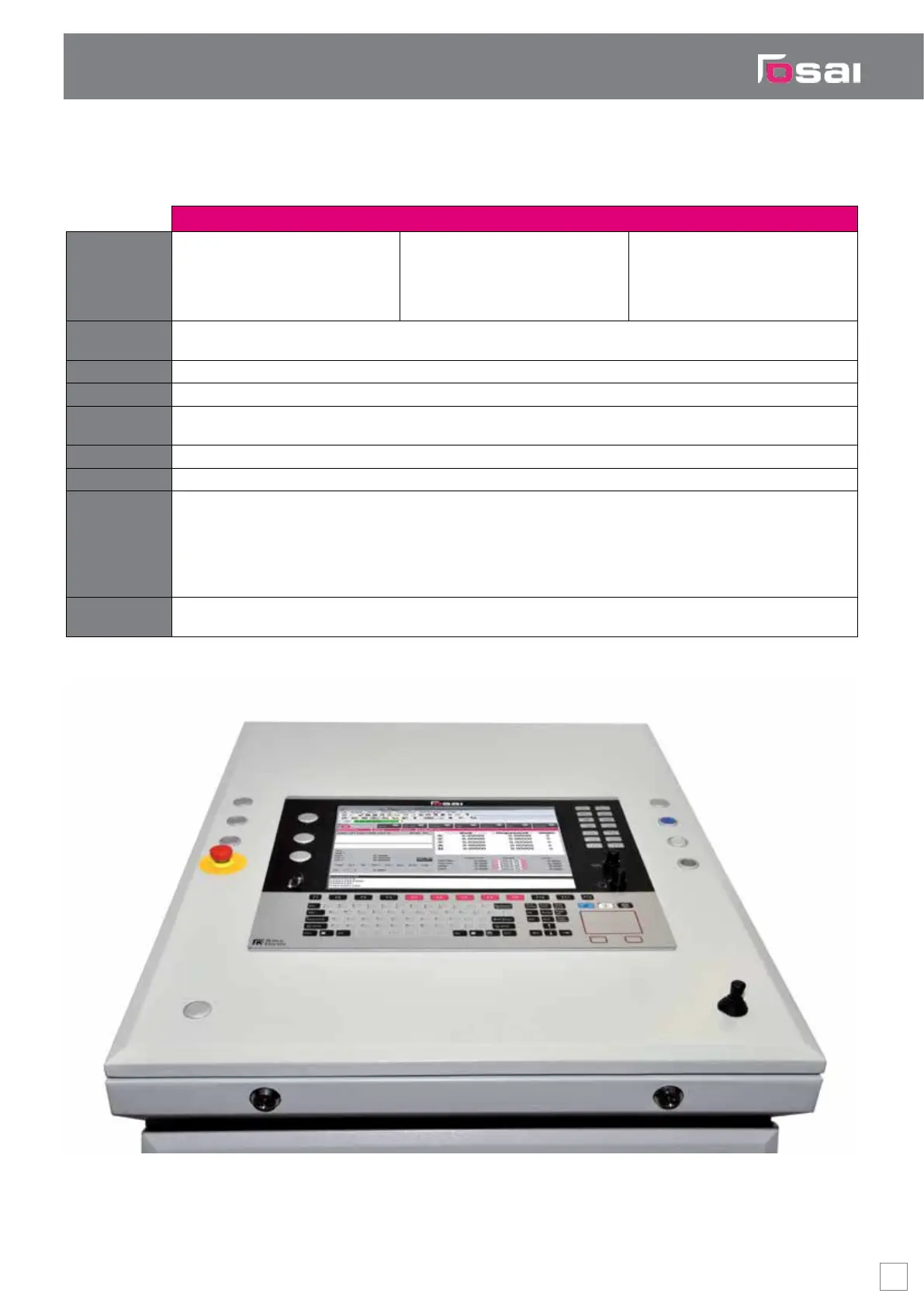

Operator

Interface

LCD 15” display, Touch Screen,

industrial keyboard and touch-

pad, E-Stop, buttons dedicated to

machine functions, Joystick

(max 2)

Ofce Standard Monitor, keyboard

and mouse (not supplied).

Requires a mechanical kit for

assembly. Possibility of adding an

Ofce PC, Joystick (max 2)

LCD 6,5” TOP5 portable panel,

Touch Screen, E-Stop, HPG,

buttons dedicated to machine

functions

CNC

OPEN-XS with Atom CPU, OPEN-M with Celeron M CPU, OPEN-XL

with Core 2 Duo CPU

Software Single or Double Operating System with software OPEN-20 or OPEN-30

Applications OPENCut Plasma, OPENCut Laser and OPENMill

I/O Modules

OPENrio SL modular I/Os which can be increased up to 96 I/O

(digital and analog)

Axes Up to 8 servo-drives with currents of 3A, 6A, 12A RMS

Splindle Spindle servo drive (from 1kW to 11kW)

Motors

Brushless servo-motors with or without brake

OS3 line:

400V with Sincos transducers (incremental or absolute). From 0,6 to 2,8 kW

XML line:

400V with incremental encoder. From 0,9 up to 3kW

200V with incremental encoder. From 0,1 up to 1,4 kW

Safety

Double contactor, safety relay (optional), STO on all servo-drives,

emergency button

OPENcontrol Technical overview

61

Loading...

Loading...