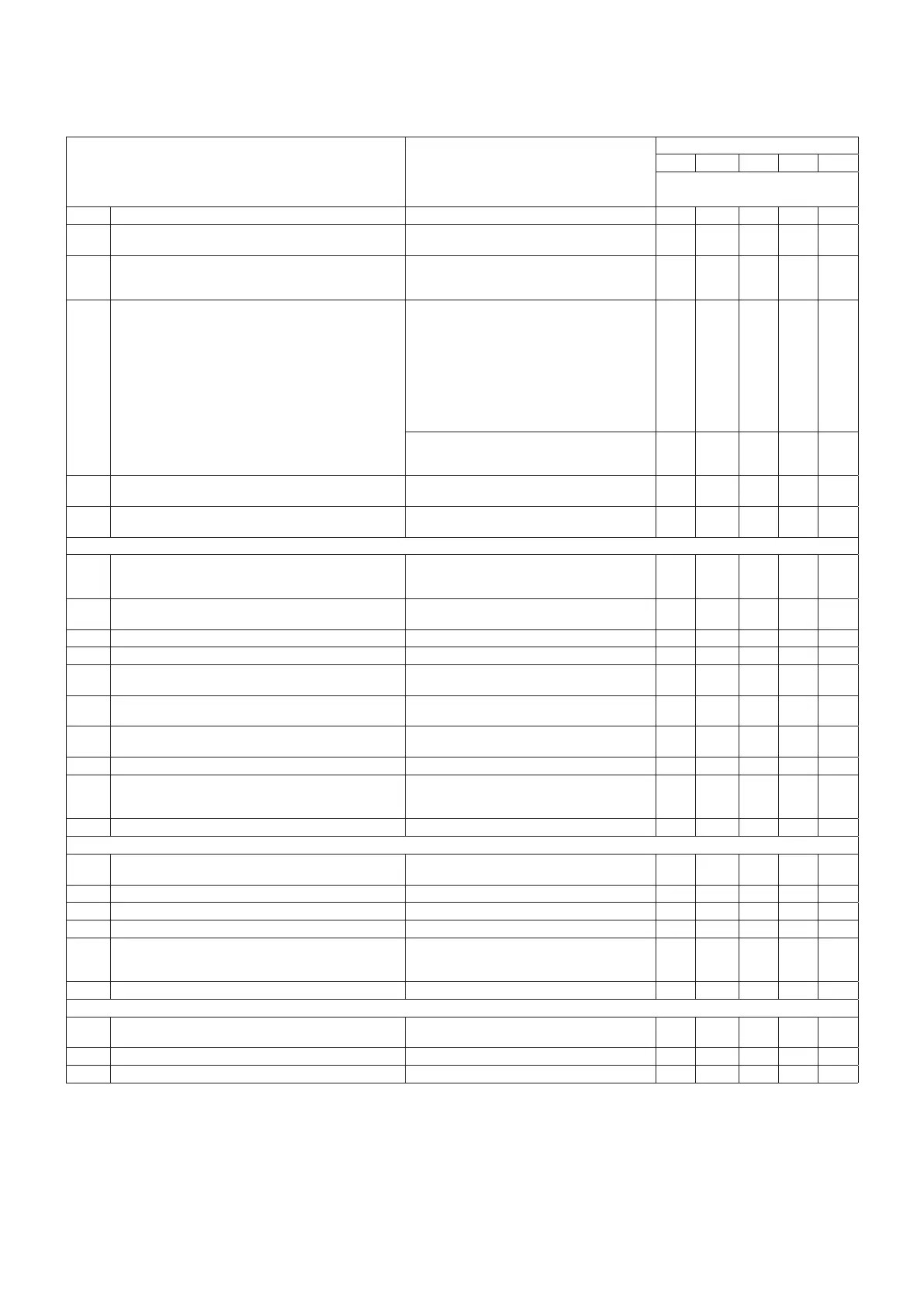

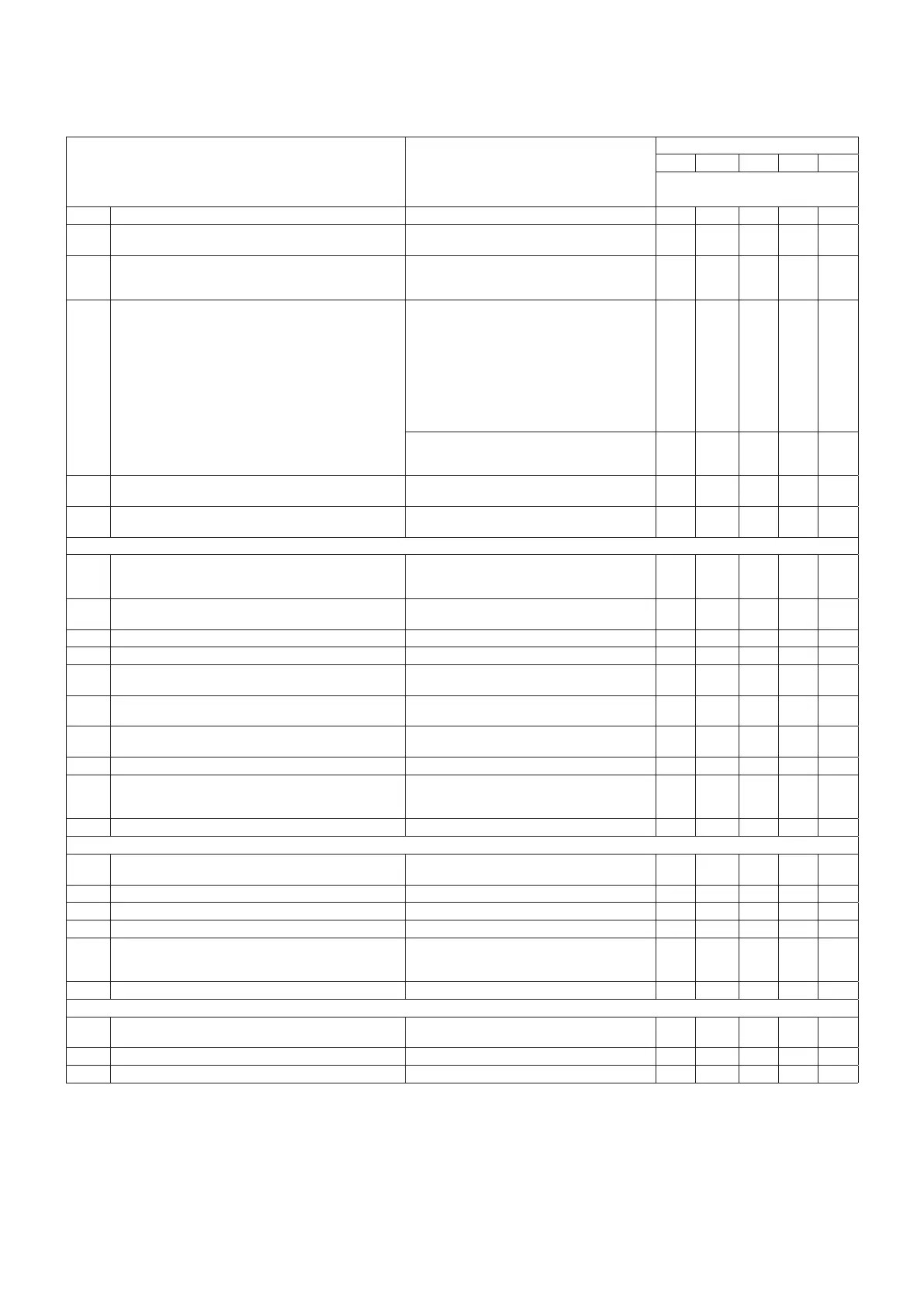

43

Tasks per components Actions

Months

1 3 4 12 24

Recommended inspection

and maintenance interval

3.10 Check fi lter cleanliness Clean

✘

3.11

Check that the hydraulic circuit is fi lled

properly

✘

3.12

Check the condition of the expansion tank

(presence of excessive corrosion, or gas

pressure loss)

Replace if required

✘

3.13 Check the water pump

If the unit has not been used for a long

time, manually rotate the pump shaft

and check that it turns freely.

For a unit equipped with a double

pump, it is recommended to switch

from one pump to the other every

month or to check that the pump

shaft turns freely to prevent the liners

sticking.

✘

Change the pump liner after 15,000

hours running with anti-freeze or

25,000 hours running with water

✘

3.14

Verify that low water pressure sensor works

perfectly

✘

3.15

Record the water temperatures at the plate

heat exchanger inlet and outlet

✘

4 - Electric circuit

4.1

Check the electrical voltage applied to the

unit, which must remain stable within the

tolerances specifi ed in the information plates

✘

4.2

Check that the main supply cable is void of

alterations likely to impact the insulation

Replace if required

✘

4.3 Check the grounding of the metallic structure Repair if required

✘

4.4 Inspect the contacts Replace if required

✘

4.5

Check that all electrical connections of the

device are tight

Tighten if required

✘✘

4.6

Check the thermal protection relays of the

motors

Replace if required

✘

4.7

Check the nominal intensity and condition of

the fuses

✘

4.8 Check the condition of the condensers

✘

4.9

Clean the electrical cabinet with compressed

air to remove any dust or other contaminants

building up

✘✘

4.10 Check the motor windings are insulated

✘

5 - Fan(s)

5.1

Check for lack of contamination, corrosion or

damage

Clean if required

✘

5.2 Check proper fastening of the fan Tighten if required

✘

5.3 Check the vanes to guarantee balancing Clean if required

✘

5.4 Check the bearings for noise Repair if required

✘

5.5

Check the condition of the grease and

greasers (unless permanently lubricated)

Re-grease if required (Lithium soap

grease DIN 51825-K3N for fans type

K, K1, K2)

T >

70°C

✘

5.6 Check the condition of the fan motor

✘

6 - Control

6.1 Check the condition of the alarms

Acknowledge them after taking them

into consideration

✘

6.2 Check the operating set-points

✘

6.3 Check the operation of all probes

✘

Loading...

Loading...