12

6000 Series Purge/Pressurization System

I/O Manual

Pneumatic requirements

Protective gas supply

The protective gas supply to the enclosure system must

be a clean, instrument quality compressed air or inert

gas ltered to a minimum of 40 microns. It must contain

no more than trace amounts of ammable gas, vapor, or

dust.

The protective gas supply compressor intake must

originate in a nonhazardous location. The suction

duct passing through a hazardous location and the

protective tubing and piping must be fabricated from

noncombustible materials suitable for the prevailing

hazardous and environmental conditions.

The protective gas supply provided must be able to

handle the ow and pressure requirements for purging

and pressurization (see page 66, Establishing connection

sizes, lengths & bends).

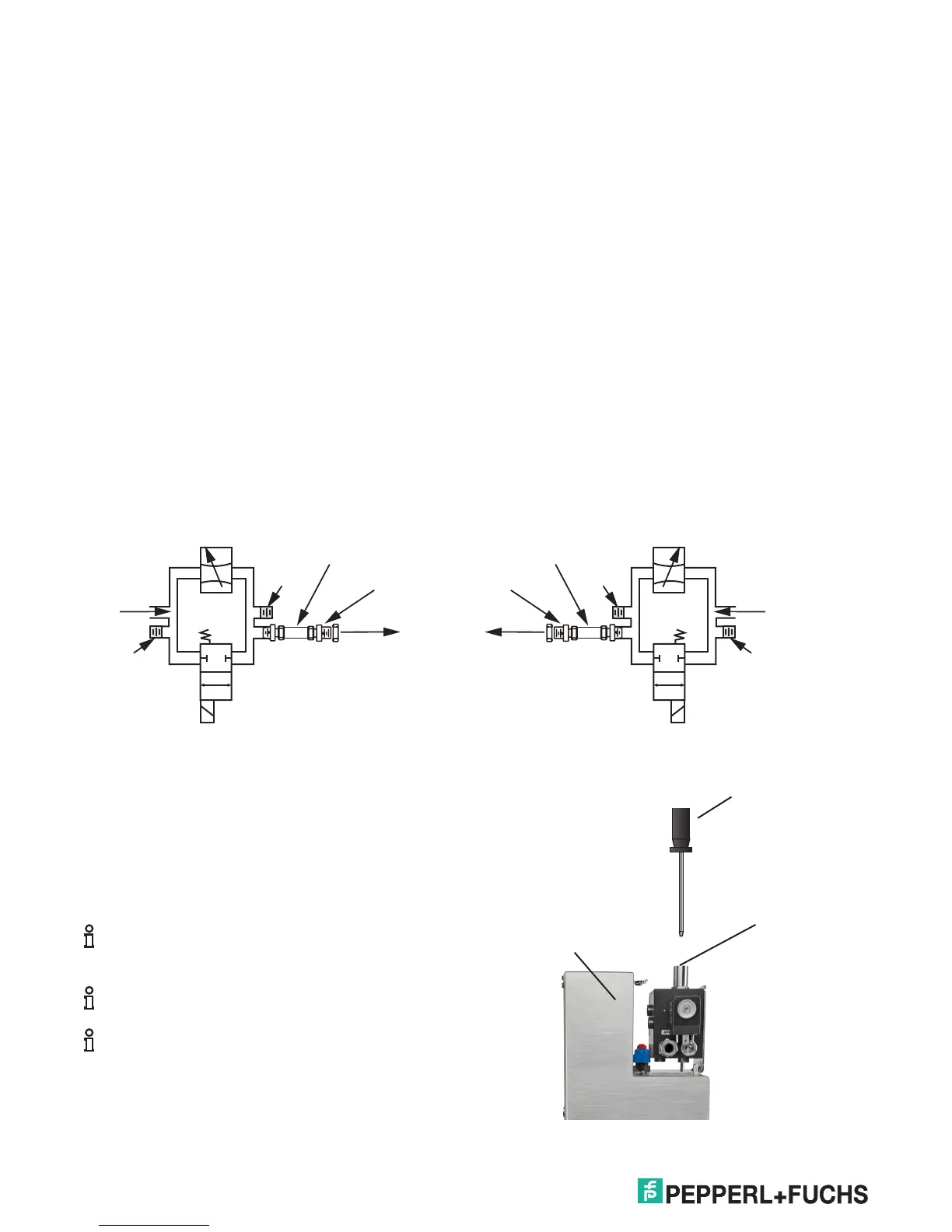

Pressurization adjustment

To adjust, use a at head screw driver inserted into the

needle valve of the manifold as shown. Turn clockwise to

decrease the ow, counter-clockwise to increase the ow.

The maximum number of complete rotations allowed is

ve (5).

Diagram shown is without plumbing. See the

diagrams on the following page for plumbing

installation.

Unit must be powered to get a pressure reading.

When delivered, the system is in its default mode

(fully automatic [FA]). It may be easier to adjust

safe pressure in standard (STD) or

semiautomatic (SA) mode so that the system

does not automatically begin purging when

energized.

Pneumatic connections

The 6000 series system requires only two pneumatic

connections to the protective enclosure, one for the

exhaust for the vent mounting and the other for the

protective gas supply for purging and pressurization.

The vent requires a single 1 1/2" conduit knockout (Ø2"

[50.8mm]) hole in the enclosure. A lock ring with gasket

for sealing are provided. The control unit for the 6000

series provides a compression tting with a lock ring and

washer connected to a 3/8" tube. All tubing and ttings

are 316L (UNS S31603) stainless steel. A single hole

into the enclosure as noted on the mounting template will

provide the installation for this tting.

For replacement of this tubing use only 3/8" tubing with

wall thickness of 0.035" (0.9 mm).

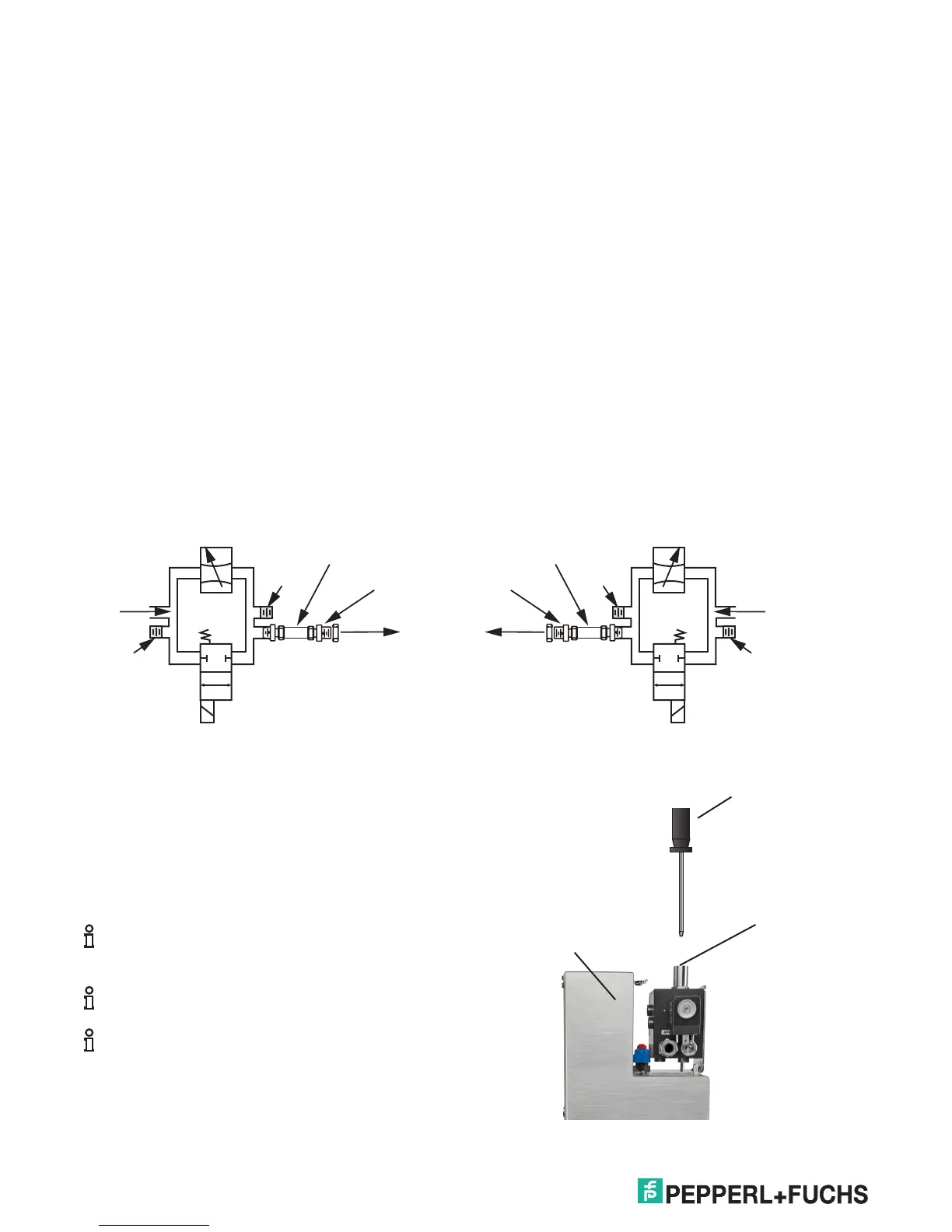

The 6000 series control unit with the manifold can be

top, bottom, right, or left-hand mounted on the enclosure.

However, the manifold connections may have to be

reversed as shown below.

Needle valve

Plug

3/8" tubing

EFC-6-SS

Protective

gas supply

Plug

Solenoid

valve, EEx io

2/2 way

Supply

to enclosure

Needle valve

Plug

3/8" tubing

EFC-6-SS

Protective

gas supply

Plug

Solenoid

valve, EEx io

2/2 way

Supply

to enclosure

Note

Note

Counterclockwise

rotation

increases ow

Clockwise

rotation

decreases ow

Flathead screwdriver

Needle valve

in manifold

6000 control unit

housing

MAXIMUM of ve (5) turns

Loading...

Loading...