15

6000 Series Purge/Pressurization System

I/O Manual

4. Put 2 of the mounting screws in the back of the

control unit to align with the key holes in the

mounting plate.

5. Hang the control unit onto the plate. Slide the unit

towards the enclosure so that the EFC-6-SS tting

is in the proper location.

6. Tighten the 2 bolts. Put the other two mounting

bolts in place and tighten.

7. Place the EFC-6-SS bolt in position and tighten.

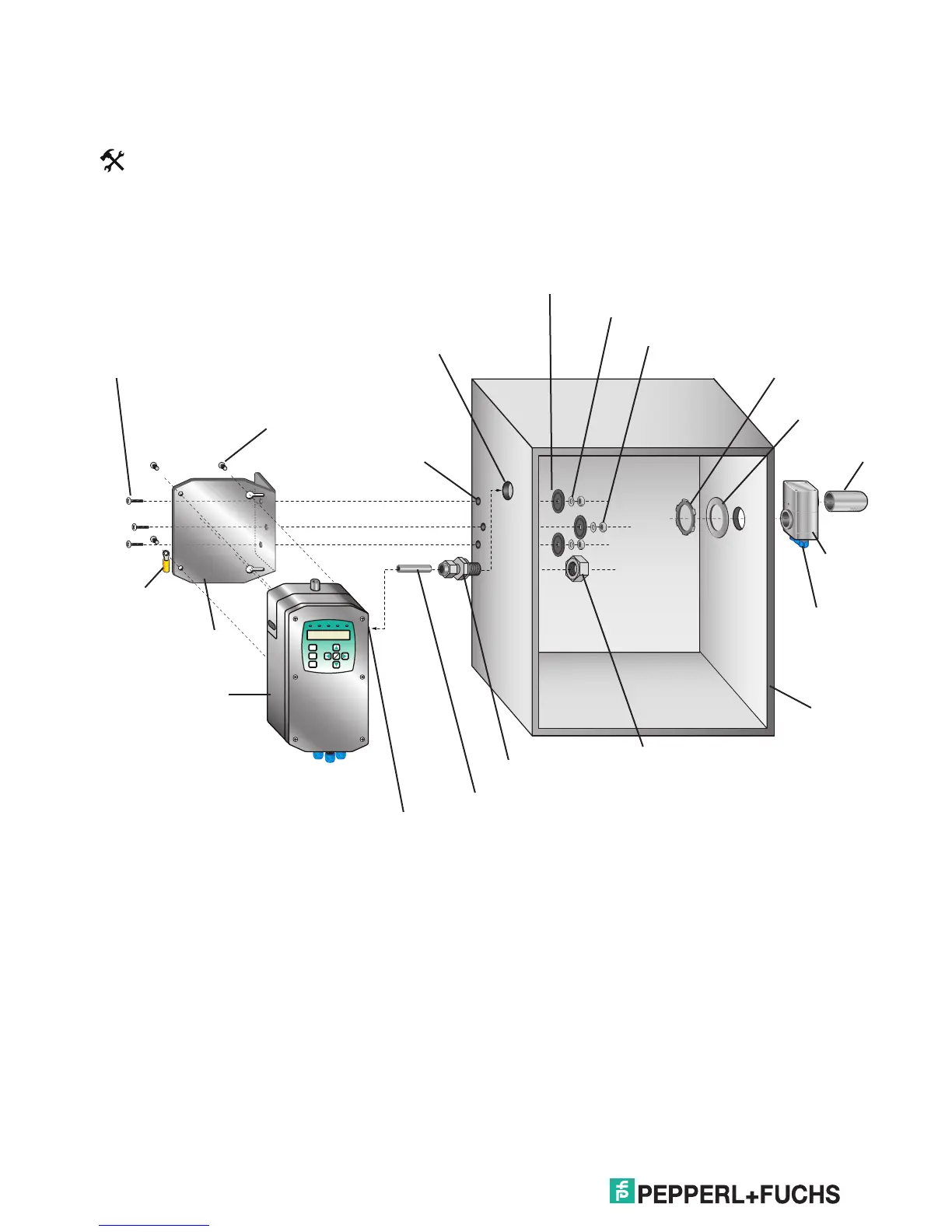

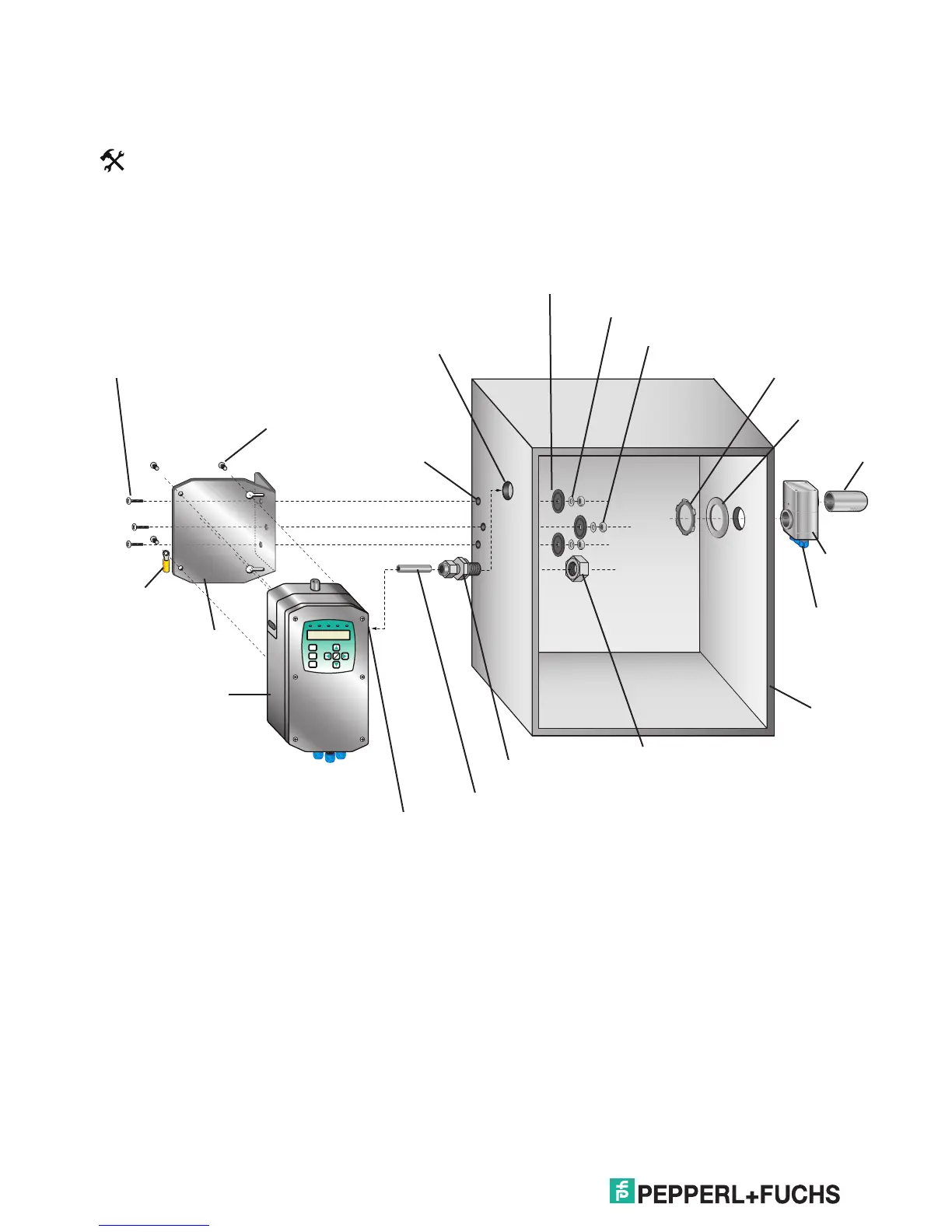

6000 Control unit with housing "WH"

Tools:

Appropriate sized drill bits or knockout holes

1 1/16" open end box wrench

Bolts: 1/4-20 (provided),

hole clearance = 0.27" (6.86 mm) diameter

EFC-6-SS (provided):

hole clearance = 0.61" (15.54 mm) diameter

1. Drill holes using template. Check the scale if

printing an electronic version.

2. Assemble tubing and tting to control unit. Install

on the "Out" port of the correct side.

3. Bolt mounting plate to the enclosure. Type 4X

washers must be mounted inside the enclosure.

Tighten to 60 – 80 in-lb (16.38 – 18.08 Nm).

Locking nut

w/grounding screw

(included)

Seal gasket

(included)

EPV-6000

Vent cap

(included)

1/4-20 nuts (3 included)

Seal washer (3 included)

Lock washer (3 included)

EFC-6-SS (included)

Enclosure

EFC-6-SS nut (included)

3/8" stainless steel tube, 2.5" (65 mm) long (included)

3/8" ferrule tting (included)

6000 control unit

Ø 0.27" ( 6.86 mm)

hole (3x)

Ø 0.61" (15.54 mm) hole

Mounting bracket

(included)

1/4-20 pan head bolts

(3 included)

Vent cable

(included)

Grounding lug

(included)

1/4-20 pan head

w/lock washer screws

(4 included)

Loading...

Loading...