56

6000 Series Purge/Pressurization System

I/O Manual

Maintenance and repair

1. The 6000 purge and pressurization system

does not require special maintenance except

replacement of pneumatic lters, when used,

and normal periodic functional checks, including

pressure and ow readings within specications

contained in this manual. When checking whether

the pressure and ow measurements of the EPV-

6000 vent are within specications, use calibrated

equipment to determine measurements, or contact

a Pepperl+Fuchs representative or the factory to

send back the EPV-6000 vent for pressure and ow

verication.

2. The purge and pressurization system, when

operated in conjunction with a hazardous area,

must not be modied. If there is a defect, the

product may need to be replaced. Repairs must be

performed only by a Pepperl+Fuchs specialist who

is specically trained and authorized to repair the

defect.

3. Any replaceable fuses must be replaced with specic

fuse ratings and type, as written in this manual under

Specications.

4. When servicing, installing, and commissioning,

the area must be free of all combustible material

and/or hazardous explosive gas. Only the terminal

compartment of the control unit is accessible to the

user. Not under any circumstances, shall the control

unit, user-interface, or vent, be taken apart. The Ex d

housing cover shall only be removed when power is

removed from the device or the area is known to be

safe.

5. Any cable glands that require replacement shall be

replaced with the same model or another approved

cable gland that meets the area classication.

6. When replacing the EPCU, the area must be free of

hazardous gas and/or dust and power removed from

the EPCU, enclosure contacts, and auxiliary contacts.

Two screws on the bottom of the Ex d enclosure

need to be loosened but not removed. Twist the

EPCU clockwise and lift it out of the Ex d enclosure.

Reverse to install new EPCU.

Contact customer service for an RMA (return

merchandise authorization).

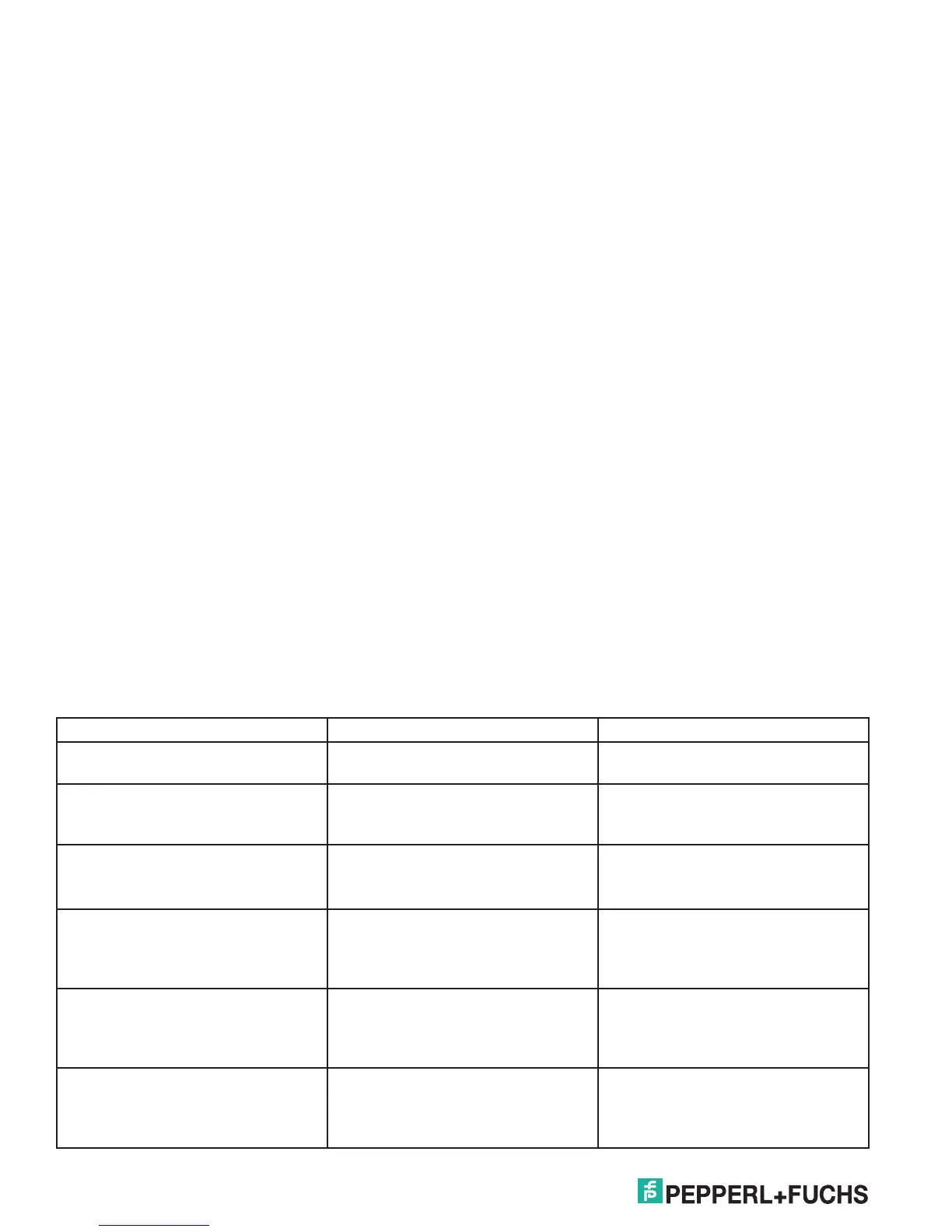

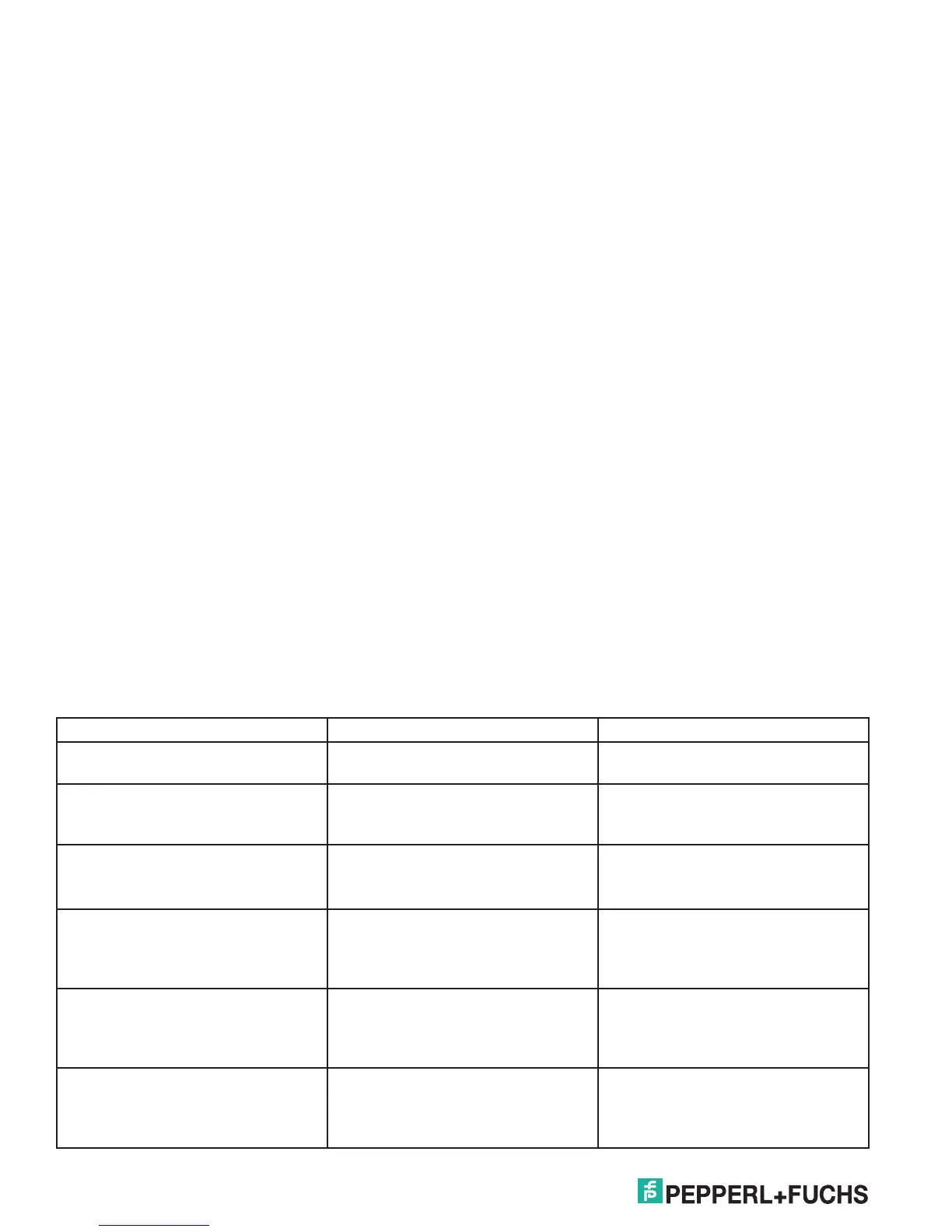

Alarm and fault conditions

The 6000 purge controller can indicate certain alarm and fault conditions when they happen. The alarm condition

is indicated on the display under the Alarm/Fault LED and will blink for an alarm and remain solid for a fault. The

alarm will not disengage enclosure contacts if they are on but can be directed to the AUX alarm contact. The fault will

disengage enclosure contacts.

Below are the alarm descriptions:

Alarm Description Cause

NO SAFE PRESSURE Enclosure pressure is below

minimum safe pressure

-No purge supply

-Enclosure leakage too great

MAX PRESSURE Enclosure pressure is above the

maximum pressure allowed

-Purge supply pressure too much

-EPV-6000 vent is blocked or not

installed

LOW PRESSURE Enclosure pressure is below the

alarm pressure but above the min.

safe pressure

-Purge supply capacity is not keeping

up

-Enclosure is starting to leak more

INPUT 1-4 BROKE/SHORT When SRM is selected, then a wire is

broken or shorted going to the switch

input

-SRM is selected and not installed on

the switch input

-Broken or shorted wire to switch/

SRM

DOOR OPEN Causes the purge system to reset

and will not start again until clear

- Signal from switch input activated

door open

-Shorted wire going to switch input

with no SRM selected

IMMEDIATE SHUTDOWN Causes the purge system to reset

and will not start again until clear

-Signal from switch input activated

immediate shutdown

-Shorted wire going to switch input

with no SRM selected

Loading...

Loading...