58

6000 Series Purge/Pressurization System

I/O Manual

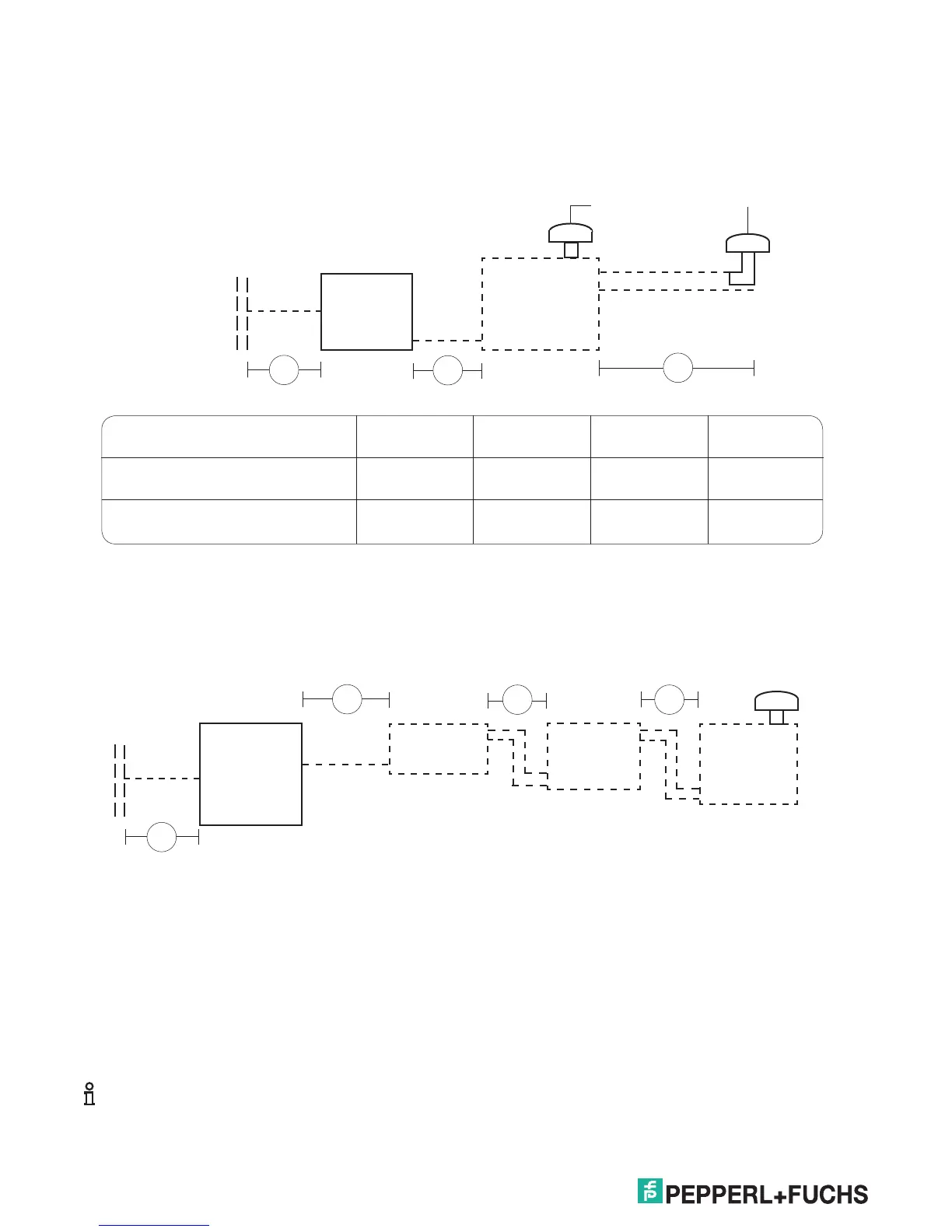

Establishing connection sizes, lengths & bends

Typical single protected enclosure connections with vent

Protected

enclosure

B

Enclosure protection vent

(required)

E

Supply

1/2" protective

gas supply

header

Enclosure

protection

system

Maximum tubing / pipe length and

maximum number of bends / elbows

1/2" O.D. tubing

or

1/2" I.D. piping

6.1 m (20 feet)

10 bends

3/8" O.D. tubing

Model 6000

*Tubing or pipe diameter

Tubing and pipe must be fully reamed

Enclosure

supply

System

supply tubing

6.1 m (20 feet)

5 bends

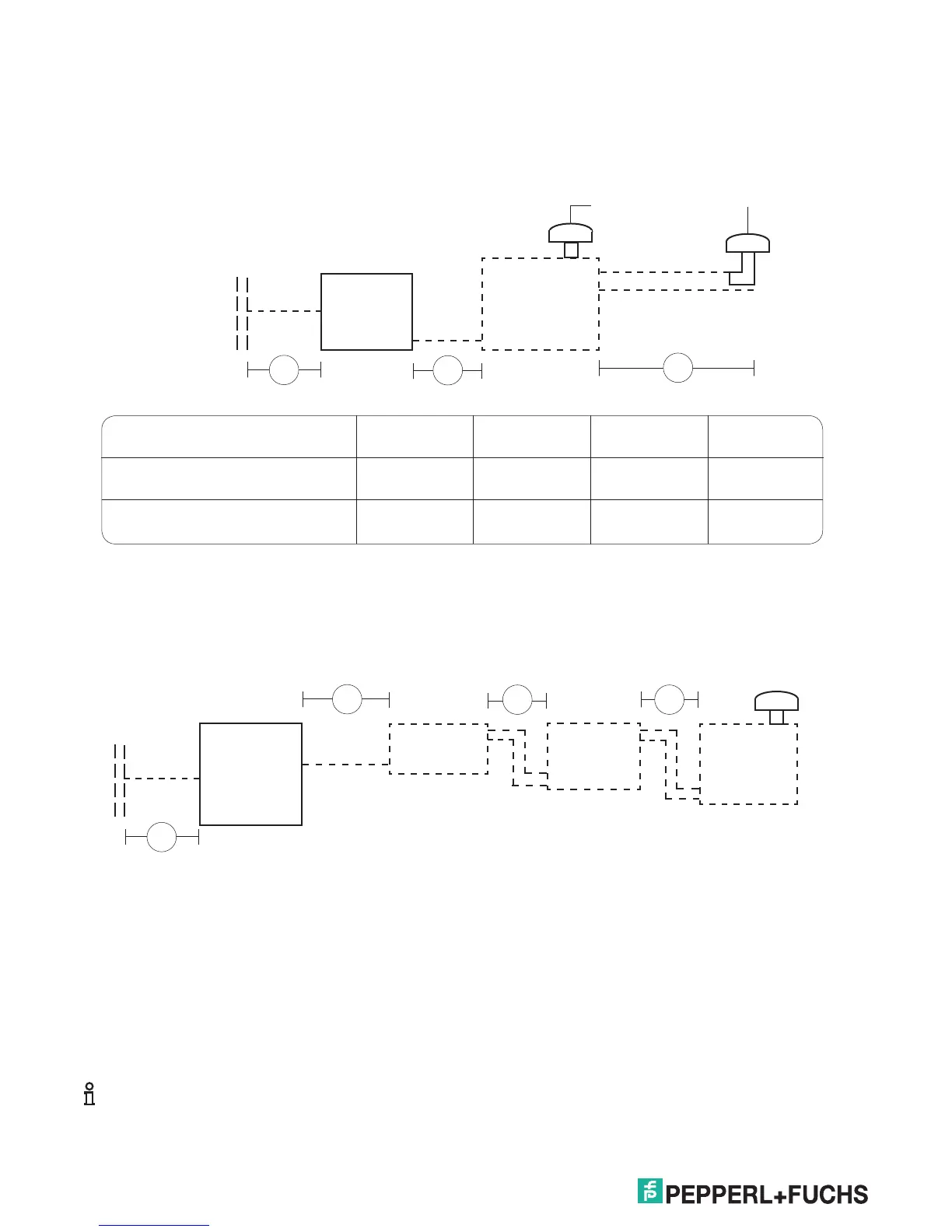

Multi - enclosure

connections

1-1/2" I.D. pipe

fully reamed

3.1 m (10 feet)

5 elbows

Optional remote

venting

1-1/2" I.D. pipe

fully reamed

3.1 m (10 feet)

5 elbows

A*

B*

E

D

Enclosure

protection

system

Protected

enclosure

Protected

enclosure

D

Supply

B

Typical multiple protected enclosure connections

1/2" protective

gas supply

header

A

A

D

Helpful hints

To ensure adequate protective gas ow to the protected enclosure(s), all piping and tubing must be fully reamed.

Precautions must be taken to prevent crimping and other damage to protective gas piping and tubing.

When protecting multiple enclosures with a single enclosure protection system, the enclosures should be connected

in series from the smallest to the largest to ensure adequate protective gas ow.

Protected

enclosure

*Smaller tubing and longer lengths allowed but ow will be decreased

NOTE: Tube and pipe sizes are trade sizes and are NOT equal in inside

diameter. DO NOT substitute tube for pipe with the same trade size.

Flow rate will also be dependant on the regulated pressure source

Loading...

Loading...