Adjustment

5

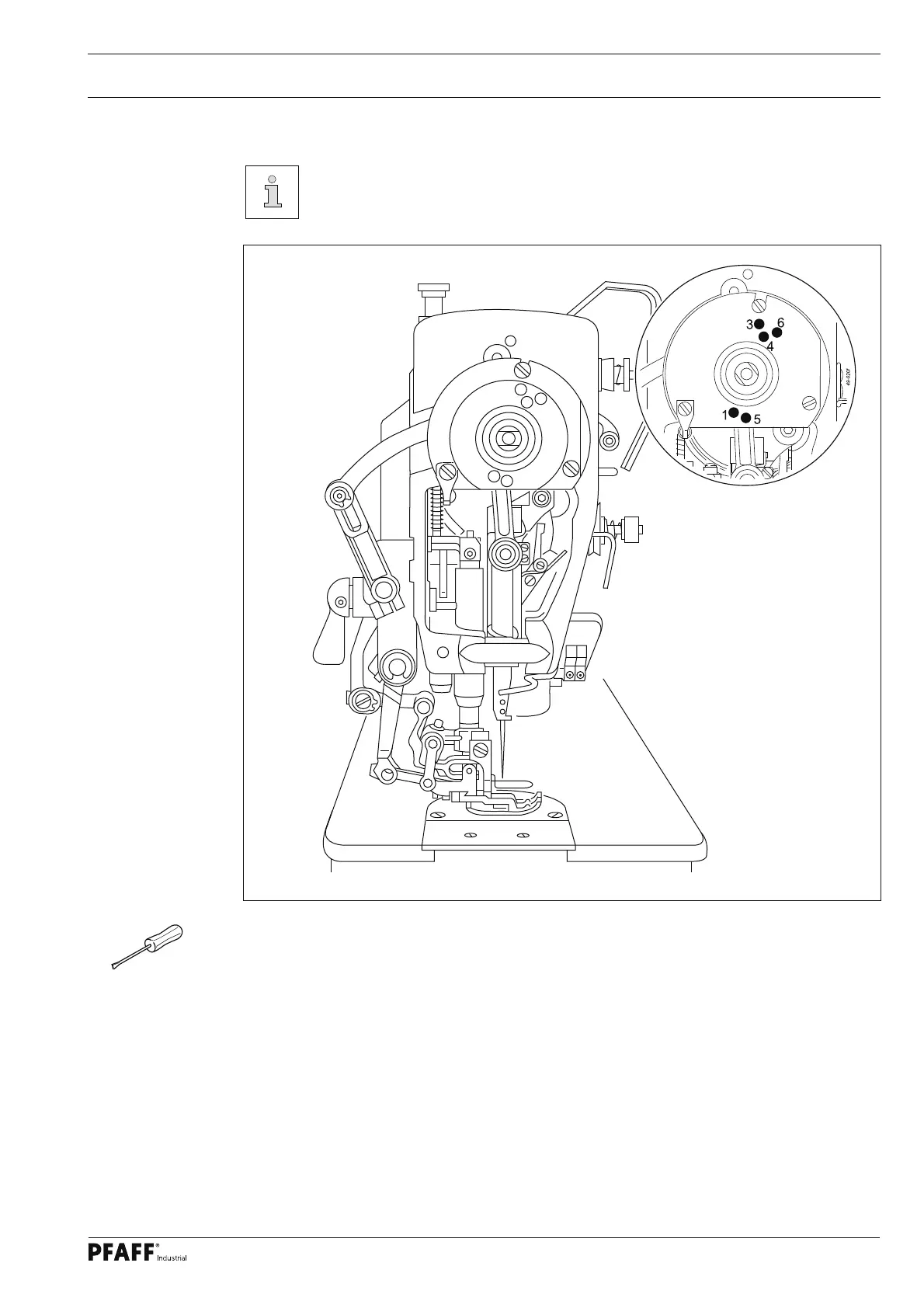

1.05 Checking and adjusting aid

By blocking holes 1 to 6 with a pin it is possible to accurately fi x the required

needle bar positions.

● Turn the balance wheel until the needle bar is roughly in the required position.

● Insert the blocking pin in the required hole and press against it.

● Turn the balance wheel slightly back and forth so that the pin enters the cutout in the

bearing plate behind and thus blocks the machine.

Hole 1 = 0.6 mm past top dead centre of the needle bar (0.6 past t.d.c.)

Hole 3 = 0.6 mm past bottom dead centre of the needle bar (0.6 past b.d.c.)

Hole 4 = 1.8 mm past bottom dead centre of the needle bar (needle rise position)

Hole 5 = top dead centre of the needle bar (t.d.c.)

Hole 6 = 4 mm past bottom dead centre of the needle bar (4 past b.d.c.)

Fig. 1 - 01

Loading...

Loading...