107

60. Synchronizer

The synchronizer consists of two forked light barriers, which scan two coded discs supplying four different

signals per revolution of the machine:

The handwheel must be turned twice by the operator manually, with a connected sewing mechanism.

All possible combinations of the synchronizer sensor must be covered during the process.

The revolutions counter is reduced in the display.

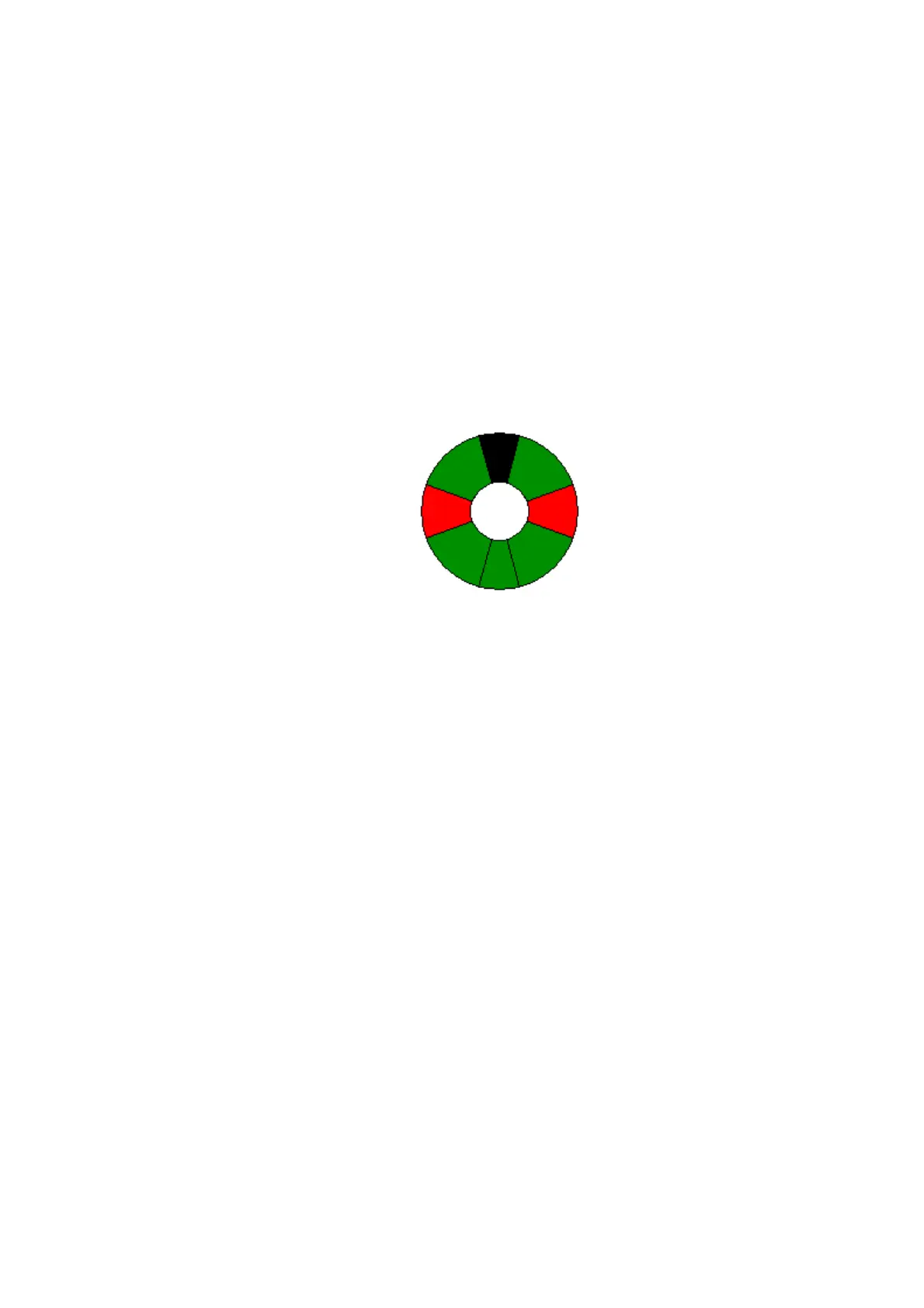

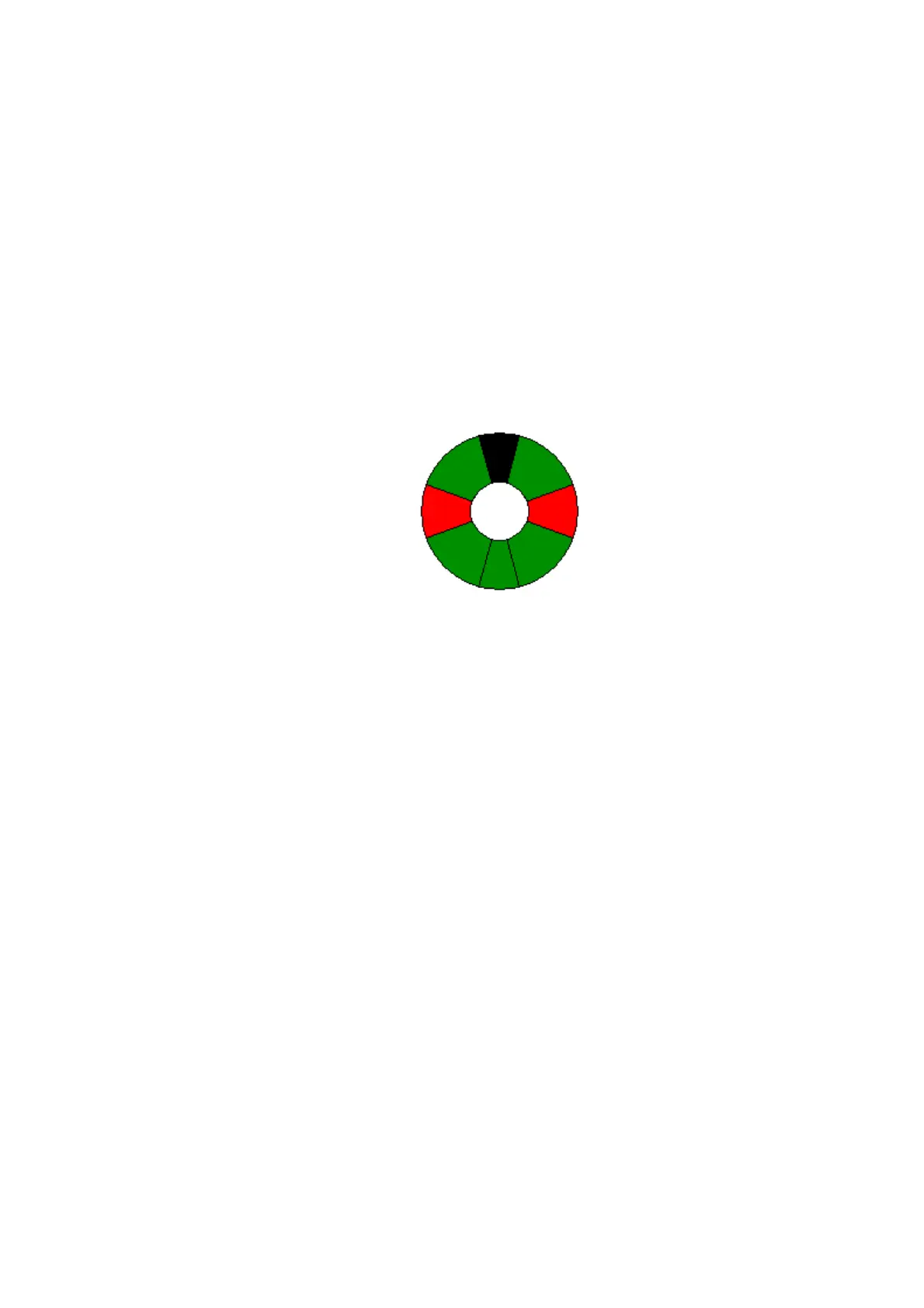

By way of a visual check, a segment consisting of bitmaps appears on the screen to indicate the current

position of the sensor.

The current position area is displayed in black (although the following illustration shows all the areas in

different colors, only the actual area will be displayed in black during the test, for example: the red area is

displayed in black while the other areas are white).

Synchronizer

OK

End = key „i“

3 * turns of hand wheel

Black: stop area for „needle raised“

Red: no stepping motor for sewing operation is allowed to move here

Green top: area for the zigzag stepping motor

Green bottom: area for the feed stepping motor

The change-over from red to green is the trigger signal for the corresponding stepping motor.

An evaluation window (OK or Error) is displayed after completion of the test.

Press the button „i“ = End (end of test with possibility to go to the next test)

The current test can be interrupted with the „i“ button.

If the „Full test“ mode is activated, the next test will be automatically executed after completion of the test.

Loading...

Loading...