17

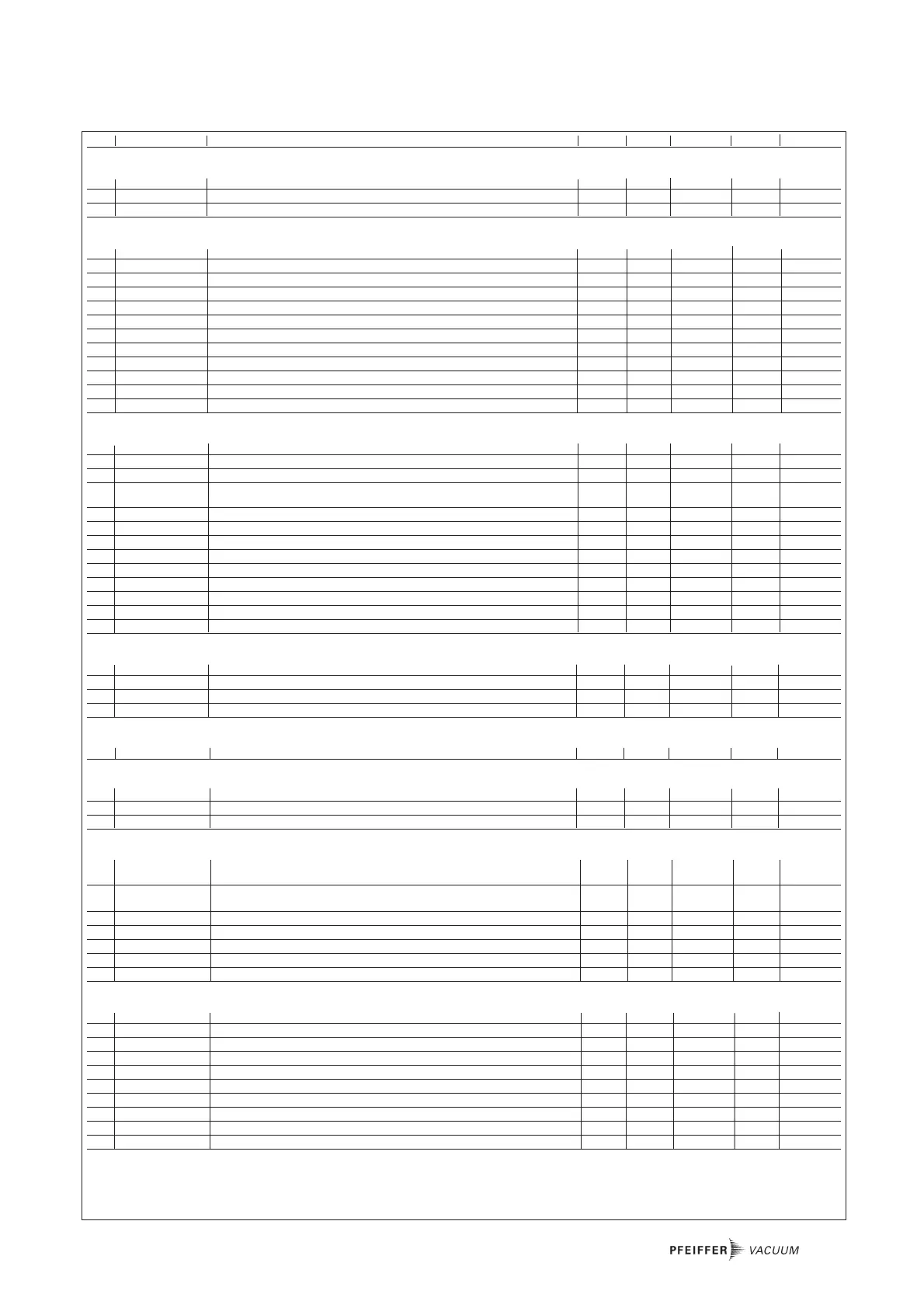

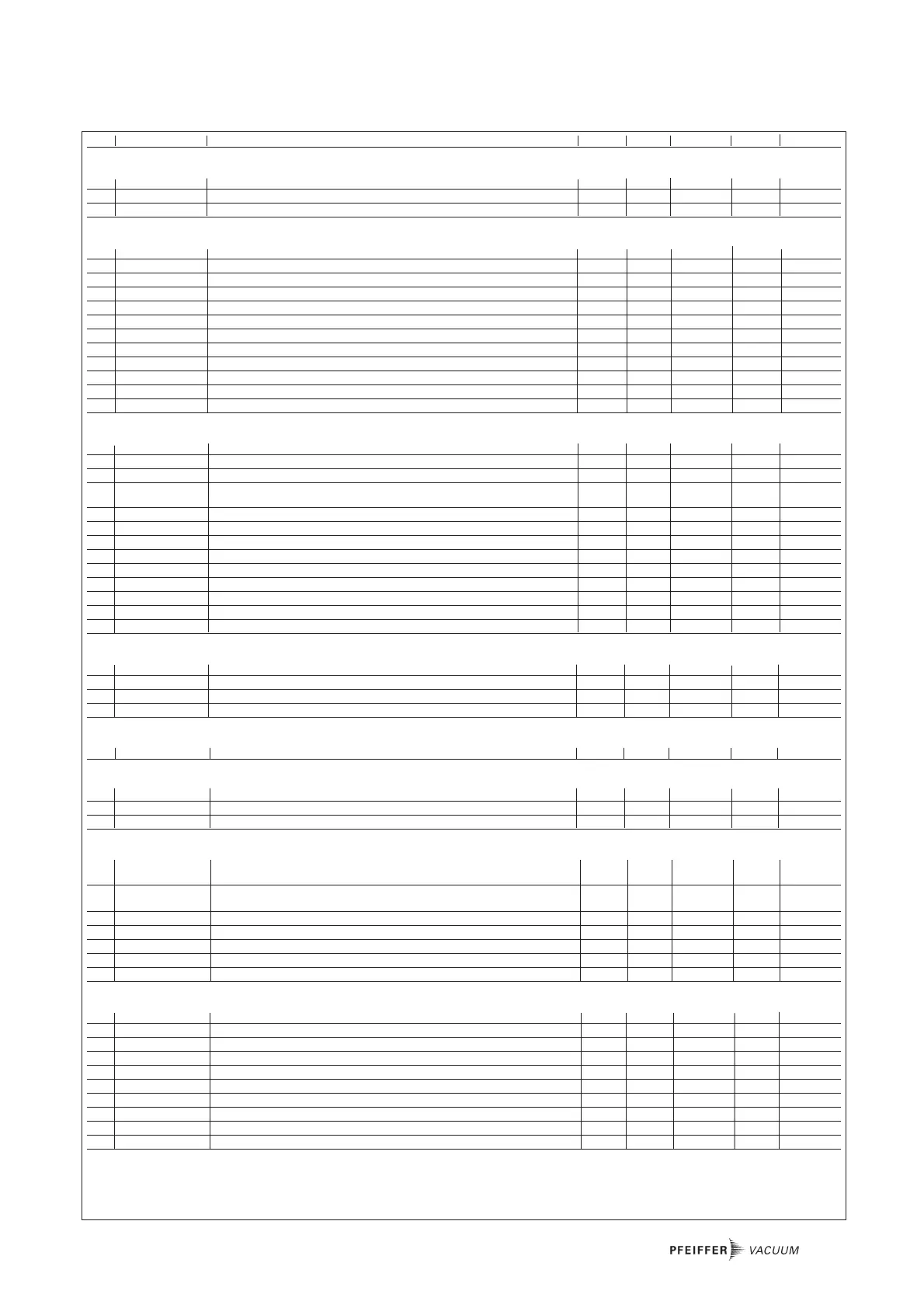

# Display Name, Description min max fact. set. RS 485 Sect.

Run up time and switch point

004 RUTime ctr Run-up time monitoring ON/OFF OFF ON ON • -

700 TMP RUTime Maximum run-up time in mins 1 120 8 • 6.

701 Switch pnt Switchpoint in % of nominal rotation speed 50 97 80 • 6.

General operating information

301 Oil defic Oil deficiency Turbopumpe – – – •

315 TMP finspd Final rotation speed TMP [Hz] 0 2000 – • 6.

310 TMP I-Mot TMP motor current [A] 0.0 25.00 – • 6.

311 TMP Op hrs Operating hours TMP [h] 65535 – • -

313 TMP DClink TMP motor voltage [V] 0 400 – • -

314 Drv Op hrs Operating hours electronic drive unit 0 65535 – • -

316 TMP power TMP motor power [W] 0 5000 – • -

319 Cycl count Cycle counter – 65535 – • -

346 TMPmotTemp Motor temperature pump 0 400 – • -

349 Drv Name Unit type electronic drive unit

6

.

ASCII 32d 6

.

ASCII 127d TCP3kA

• -

352 DrvSoftware Software motor control

6

.

ASCII 32d 6

.

ASCII 127d

• -

354 HW-version Hardware version 6

.

ASCII 32d 6

.

ASCII 127d – • -

Operating adjustment turbopump

002 Standby Stand-by ON/OFF OFF ON OFF

3)

• 6.

010 Pump stat. Pumping station ON/OFF OFF ON OFF

3)

• -

023 Motor TMP Motor turbopump ON/OFF OFF ON ON

3)

• 6.

026 OpMode TMP Operations mode TMP 0 = final rotation speed; 1=rotation speed 0 1 0

• 6.

setting mode

027 gas mode Operations mode 0=heavy inert gases; 1=other gases 0 1 0 • 6.

029 OpMode drv Selection of the voltage supply; 0=single phase; 1=threephase supp. 0 1 0 • 6.

055 ConfA01 Configuration analog output 0=rot. speed, 1=current, 2=power 0 2 0 • -

095 RstCstVals Reset to factory setting (for parameter 0.....99; 700....799) 0 1 0 • -

308 Set rotspd Set rotation speed TMP [Hz] 0 1000 – • -

309 Act rotspd Actual rotation speed TMP [Hz] 0 1000 – • -

707 TMProt set Preset rot. speed in rotation speed setting mode [%] 20.0 100.0 50.0

3)

• 6.

717 Stbyrotset Preset rot. speed in stand-by mode in [%] 20 100 66 • 6.

777 PumpRotMax Max. rotation speed [Hz] 0 2000 0 • 6.

Vent valve controlling turbopump

012 Vent enab Venting release turbopump ON/OFF OFF ON ON • 6.

030 Vent mode Venting mode 0=automatic venting ; 1=do not vent; 2=venting ”On” 0 2 0(*) • 6.

720 Vent frequ Venting frequency as a % of the final rotation speed of the TMP 40 98 50 • 6.

721 Vent time Venting time in seconds 6 3600 3600 • 6.

Gas Ballast Valve controlling OnTool Booster

052 BalstG Vlv Gas Ballast Valve ON/OFF OFF ON OFF • 3.8.

Pumping unit control

025 Vent enab Venting release turbopump ON/OFF OFF ON ON • 6.

710 BkP Poff P

min

for interval operations backing pump [W] 0 1000 0 • 6.

711 BkP Pon P

max

for interval operations backing pump [W] 0 1000 0 • 6.

Others

019 Conf. OUT2 Config. K2 0= open if mains OFF or failure, 1=dto. or warnings

2=open if mains OFF, turbo drive OFF or failure 0 2 0 • 3.

028 OpMode Rem Remote Operations mode 0=Standard operations, 1=Latch 0 1 0

• 6.

(Pin 14 “Remote” set to 1)

303 Error code Actual error code „no Err“, „Errxxx“ oder „Wrnxxx“ – • 4.

312 Drv Softw Software version electronic drive unit – • 8.

794 Param. set Parameter set 0=basic parameter set; 1=expanded parameter set;

795 Servicelin Contains service line =# of the second parameter set 309 • 4.

797 Address Unit address 1 255 1 • 6.

Table of failures

360 Past Err1 Error storage, Position 1 (last visible failure) – • 7.

361 Past Err2 Error storage, Position 2 – • 7.

362 Past Err3 Error storage, Position 3 – • 7.

363 Past Err4 Error storage, Position 4 – • 7.

364 Past Err5 Error storage, Position 5 – • 7.

365 Past Err6 Error storage, Position 6 – • 7.

366 Past Err7 Error storage, Position 7 – • 7.

367 Past Err8 Error storage, Position 8 – • 7.

368 Past Err9 Error storage, Position 9 – • 7.

369 Past Err10 Error storage, Position 10 – • 7.

3)

Function can only be affected via remote plug

• Function can be called by RS-485

5.3. Parameter overview TCP 3000, operation oriented

Loading...

Loading...