18

The factory setting for "Standby mode" is the pump operating

at 66.7 % of its final rotation speed. This value can be

changed.

➡ Select

[[PP::771177]]

«Stbyrotset».

➡ Set the standby speed within the range 20-100 %.

Standby is recommended during stoppages. This function

may also be activated via remote control or using the serial

interface.

Standby mode is not possible in rotation speed setting mode

(see item 6.8.).

Only Turbo Pumps:

Pumps with integral lubricant pump are initially accelerated

to 60 % of their nominal rotation speed in standby mode, even

if the set standby speed is < 60 % x f

nom

.

At operations below 50 % x f

nom

pump shut-

down due to lubricant deficiency is possible.

6.5. Operation Dependent On Gas Type (only

Turbo Pumps)

Gas mode adjustment

➡ select «

779944 :: PPaarraamm.. SSeett

» and set to «

11

».

➡ select «

002277 :: ggaass mmooddee

».

➡ select «

00

» for heavy inert gases (e.g. Argon), «

11

» for other

gases.

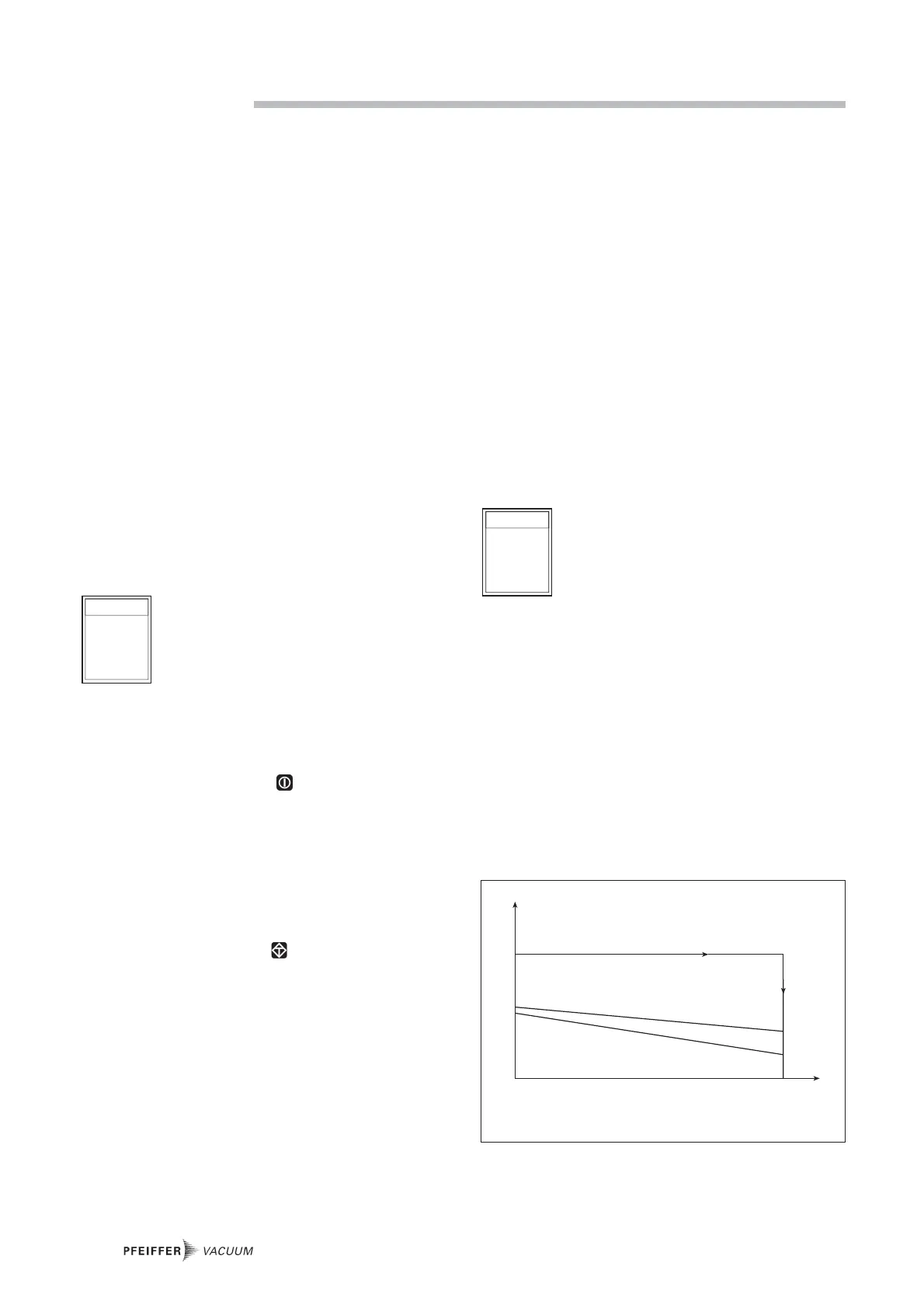

Rotor overheat protection

The TCP 3000 includes a rotor overheat protection to avoid

overheating of the rotor by high gas load and high rotation

speed. This is guaranteed by the gas type curves

[[PP::002277]]

(see

below).

In accordance to the adjustment of

[[PP::002277]]

the protection area

is defined between the power limit acceleration and the curve

B-A or D-C.

6.1. Switching On The Unit

➡ The unit contains no mains switch. After connecting with

mains voltage the Electronic Drive Unit is ready for opera-

tion.

Self test

The TCP 3000 performs a self-test. Once the self-test is

complete, the unit is ready for operation.

6.2. Setting the max. Pumping Rotation

Speed

Before putting the pump into operation, you must set the

maximum pumping rotation speed

[[PP::777777]]

. The pump will not

start unless this value is pre-set. The error message

EE777777

is

displayed. Please refer to the relevant pump operating

instructions to ascertain the maximum pumping rotation

speed.

➡ Select «

777777 :: PPuummppRRoottMMaaxx

» and enter the maximum

pumping rotation speed.

6.3. Switching On the Pump

Before the pump is switched on, the reference

value inputs and control commands (see Chap-

ter 5) must be checked to ensure their suitabili-

ty for the selected pump and application in

question, and changed if necessary.

➡ Select «

779944 :: PPaarraamm.. SSeett

» and set to «

11

».

➡ Check

[[PP::77xxxx]]

reference value inputs and

[[PP::00xxxx]]

control

commands.

➡ Switch on the pump using the key on the TCP. Alterna-

tively, switch on using the remote control or the serial

interface.

The pump begins to rotate. The rotation speed switch point

[[PP::770011]]

must be reached within the pre-set run-up time

[[PP::770000]]

. If an error code is displayed, see the error code table

in Chapter 7.

Acknowledge the error with the key to reset the run-up

time to the starting value.

Pump Normal Operation

Once the final rotation speed

[[PP::331155]]

has been reached, the

motor current

[[PP::331100]]

sets itself to a particular value,

depending on the gas throughput and fore-vacuum pressure.

6.4. Stand-by On/Off

➡ Select «

PP::000022 :: SSttaannddbbyy

».

➡ Select «

OOFFFF

» or «

OOnn

».

Loading...

Loading...