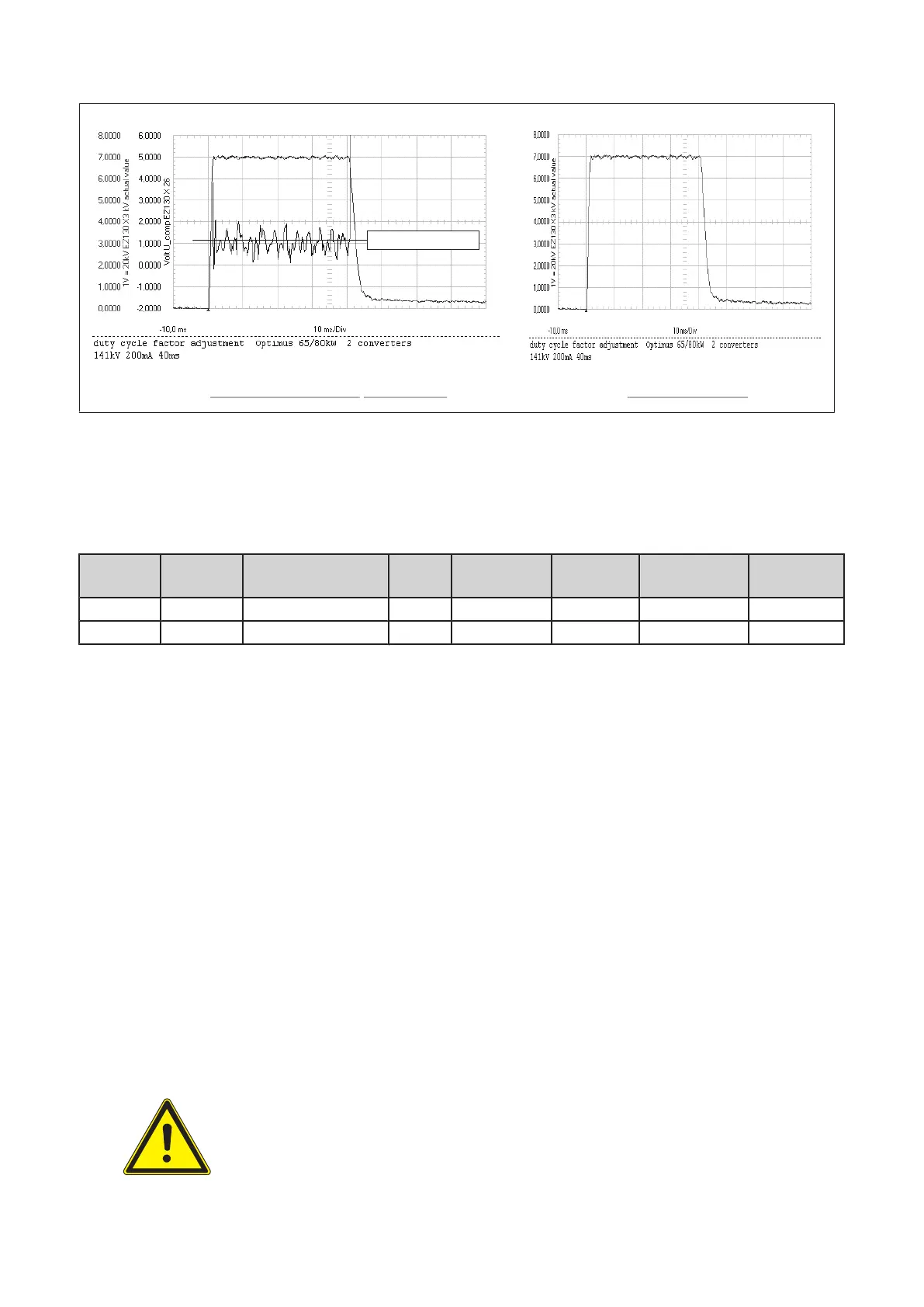

Optimus 80kW with 141kV, UCOMP = +1V AV HT with overshoot

mean value of

UCOMP

kV actual value

kV actual value +

UCOMP

(Fig. 30)

b) 125kV setting (50/65/80kW)

▪ Read the mean value of

U

COMP

for 125kV (in principle figure 29 or 30).

▪ Correct the factor duty cycle till

U

COMP

meets the required reference of 0V.

kV

setpoint

mA

setpoint

PCB type

U

COMP

Tolerance kV peak

of

AV HT

Factor duty cy‐

cle:

Date:

125kV 100mA PCB kV_control 3: +0V +1V / -0,5V 125kV

125kV 200mA PCB kV_control 4: +0V ±0.5V 125kV

Table 2: Factor duty cycle, 125kV limit

Example how to correct the factor duty cycle:

PCB kV_control 3:

▪ If the mean value of UCOMP is: > +1V increase the factor duty cycle in steps of 0.01

< -0.5V decrease the factor duty cycle in steps of 0.01

PCB kV_control 4:

▪ If the mean value of UCOMP is: > +0.5V increase the factor duty cycle in steps of 0.01

< -0.5V decrease the factor duty cycle in steps of 0.01

▪ Check also the kV peak value AV HT (not the overshoot), it must be 125kV for 125kV setpoint.

▪ Remove short link EZ130 X23 GAIN_IN.

▪ Record the results in table 2.

15.2 TUBE CONDITIONING

15.2.1 General Information

WARNING

Radiation is released during the conditioning procedure!

Converter test kit OPTIMUS for OPTIMUS 50/65/80 gen‐

erators release 3.x with converters 4512 104 7231x

Conv test Optimus CSIP Level 1 (08.0)

© 2008 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

45

Loading...

Loading...