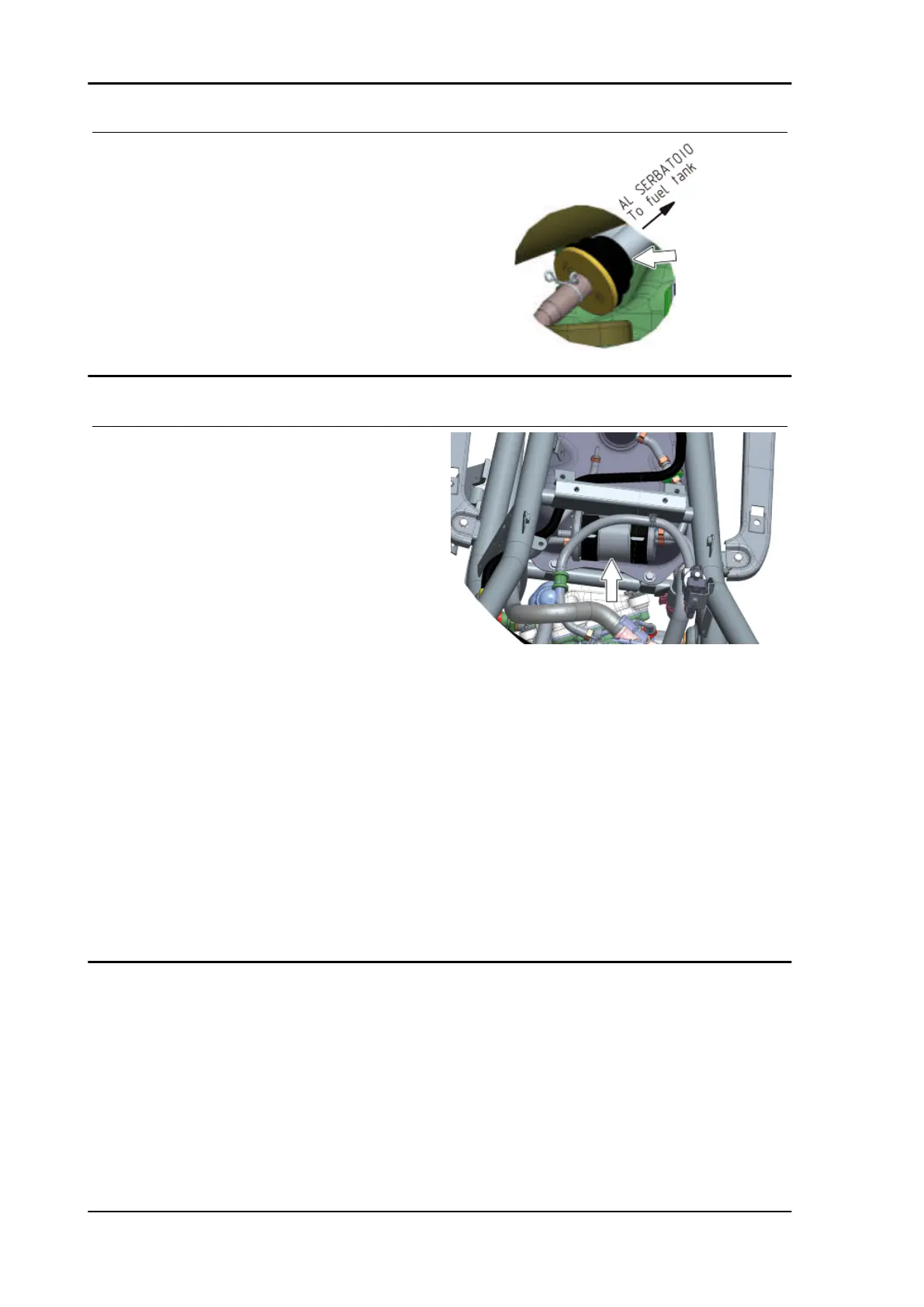

Ensure the correct orientation of the breather

valve, with the writing "TANK/RESERVOIR"

placed on the side shown in the figure.

If you detect different pressures, replace the valve.

Characteristic

Opening pressure

110 mbar

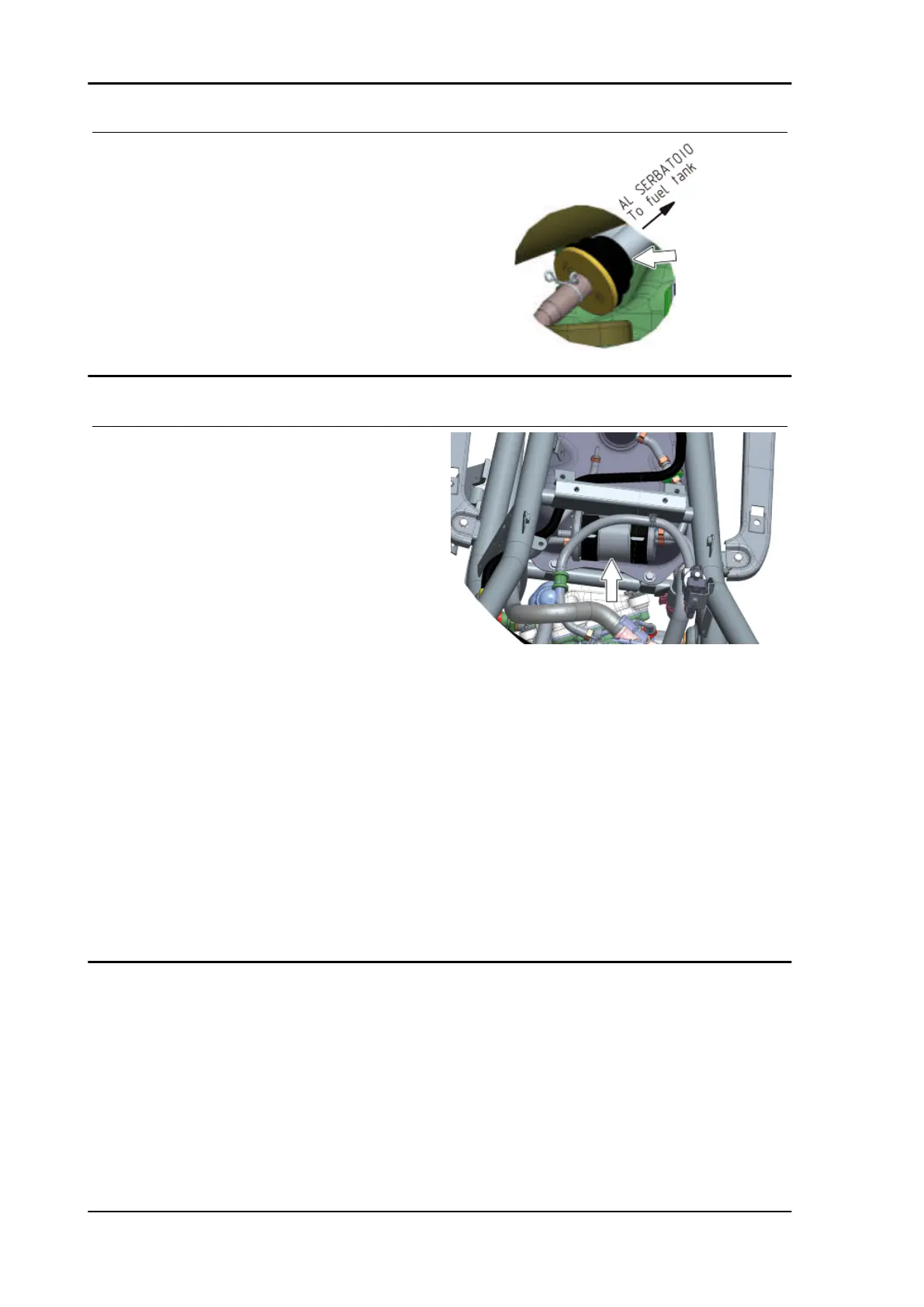

Canister inspection

The canister is essential to treat the hydrocarbons

present in the volume of gas that escapes from the

tank when there is an increase in internal pressure

(tank heating induced by the cooling radiator, by

the motor or by the external environment).

Although the amount of hydrocarbons coming

from the tank is small enough to avoid the satura-

tion of the canister, it is necessary to regenerate

the activated carbon by means of a reversed flow

of ambient air sucked by the engine.

These vacuums of pollution and carbon regener-

ation take place at each cycle of use of the vehicle.

To control the canister, it is necessary to proceed with its removal while keeping the 2 pipes connected.

•

Shake the Canister and make sure there is no noise.

•

Using a compressed air gun, blow alternately in 3 ducts and make sure that pressure does

not build inside the canister.

•

Check that the air flow is kept free and that no carbon residues escape out of any pipe.

If you detect noise, clogging or loss of carbon, replace the canister.

Maintenance Beverly 400 E5

MAIN - 66

Loading...

Loading...