PISTON-CYLINDER COUPLING CATEGORY

Name Initials Cylinder Piston Play on fitting

cylinder - piston M (84.010 ÷ 84.017)mm (83.953 ÷ 83.960)mm (0.050 ÷ 0.064)mm

cylinder - piston N (84.017 ÷ 84.024)mm (83.960 ÷ 83.967)mm (0.050 ÷ 0.064)mm

cylinder - piston O (84.024 ÷ 84.031)mm (83.967 ÷ 83.974)mm (0.050 ÷ 0.064)mm

cylinder - piston P (84.031 ÷ 84.038)mm (83.974 ÷ 83.981)mm (0.050 ÷ 0.064)mm

N.B.

THE PISTON MUST BE INSTALLED WITH THE ARROW FACING TOWARDS THE EXHAUST SIDE,

THE PISTON RINGS MUST BE INSTALLED WITH THE WORD «TOP» OR THE STAMPED MARK

FACING UPWARDS.

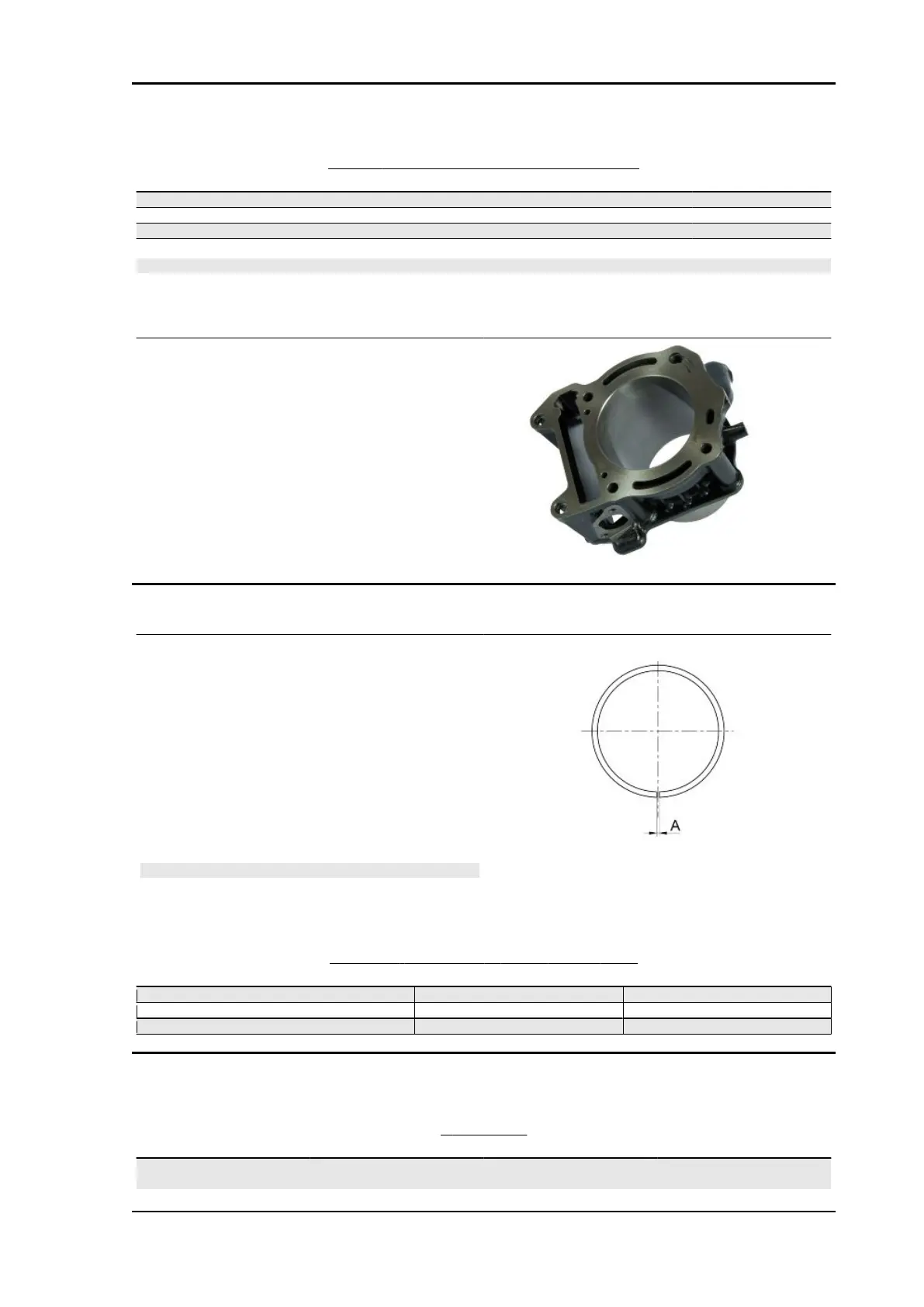

- Check that the head coupling surface is not worn

or misshapen.

- Pistons and cylinders are classified according to

diameter. The coupling is carried out in pairs (M-

M, N-N, O-O, P-P).

Characteristic

Maximum allowable run-out:

0.001 in 0.05 mm

Piston rings

- Carefully clean the seal housings.

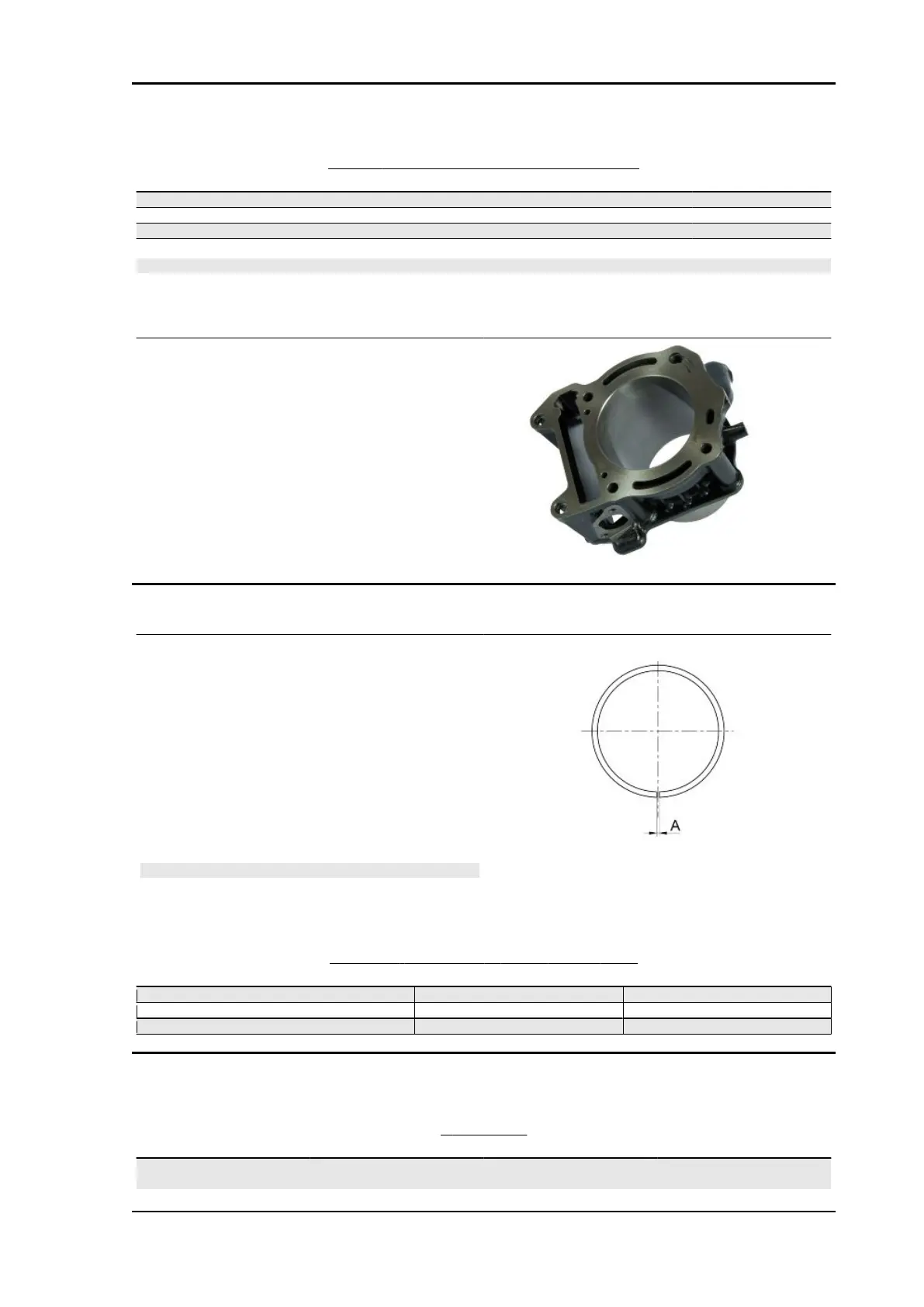

- Measure the coupling clearance between the

sealing rings and the piston grooves using suitable

sensors, as shown in the diagram.

- If the clearance is greater than that indicated in

the table, replace the piston.

- Check the clearance upon mounting (A) of the

bands:

N.B.

MEASURE THE CLEARANCE BY INSERTING THE BLADE

OF THE FEELER THICKNESS GAUGE FROM THE SECOND

SEAL SIDE.

ASSEMBLY CLEARANCE OF BANDS - SEAL RINGS

DENOMINATION DIMENSIONS ASSEMBLY CLEARANCES (A)

1st compression ring 84 x 1 mm 0.10 ÷ 0.30 mm

Oil scraper ring 84 x 1.5 mm 0.35 ÷ 0.55 mm

Oil scraper ring 84 x 2.5 mm 0.25 ÷ 0.55 mm

Crankcase - crankshaft - connecting rod

CRANKSHAFT

Titolo Durata/Valore Testo Breve (< 4000 car.) Indirizzo Immagine

Crankshaft Axial clearance between

crankshaft and connecting rod

Beverly 400 E5 Technical Data

DT - 33

Loading...

Loading...