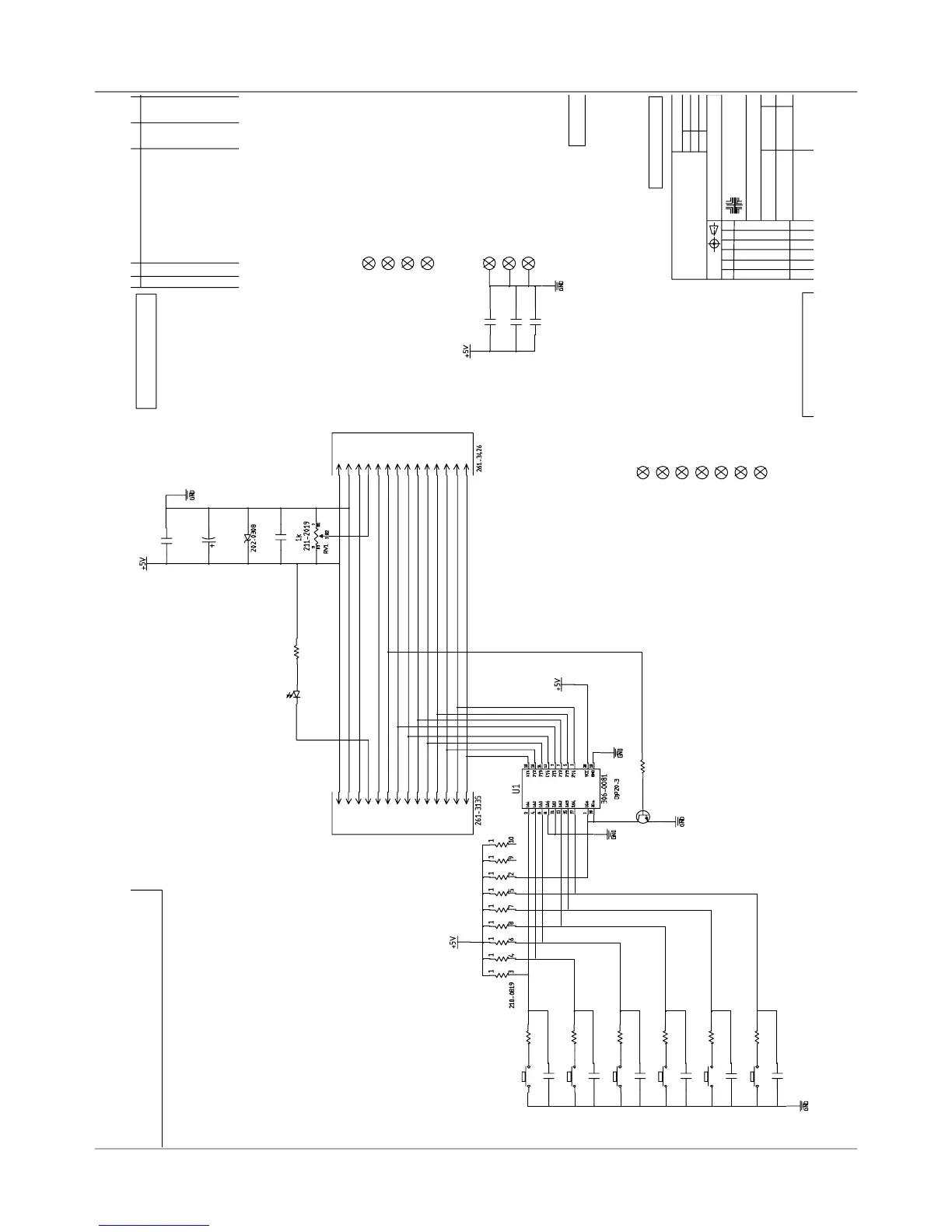

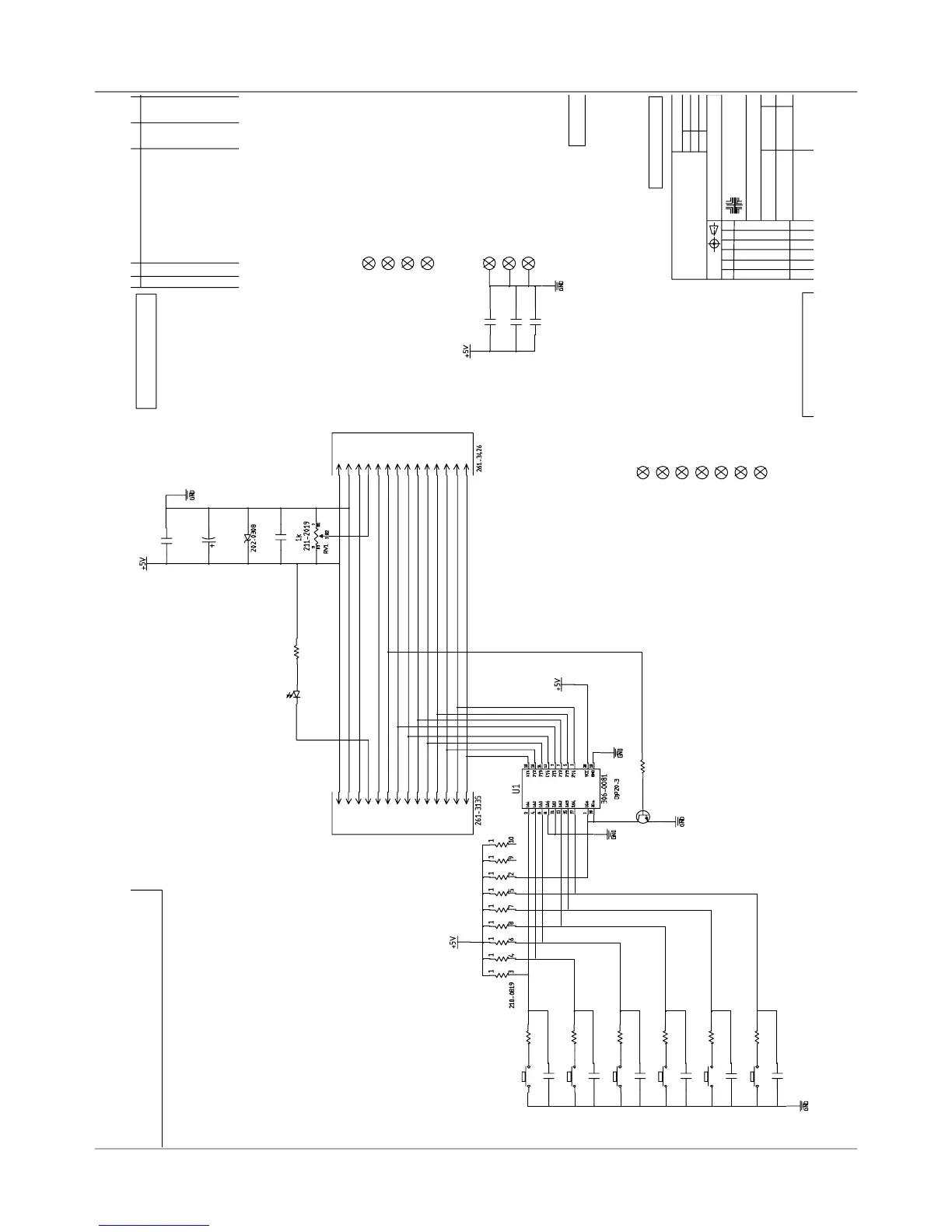

KEYRD~

AD1

AD0

AD3

AD2

AD5

AD4

AD7

AD6

CONTRAST

LCDEN

OL_LIGHT

A1

4.7k

RN1

P2N2222A

Q1

201-0144

2

1

3

1J1

2J1

3

J1

4

J1

5

J1

6J1

7J1

8

J1

9

J1

10

J1

11 J1

12 J1

13

J1

14

J1

4.7uF

206-2052

C2

0.1uF

C1

207-0512

SW1

2

1

SW2

2

1

SW3

2

1

SW4

2

1

SW5

2

1

SW6

2

1

202-0726

D1

GREEN

21

DM74ALS244AN

150ohms

247-3151

R2

4.7Kohms

247-3472

R1

Time:02:47:04 PM Date:03/01/2006

Page: 01 of 01

N

DATE

DRAWN

APPROVED

TITLE

MODE

PART NO

DATE

SCALE

CHANGE ORDER NO

PRODUCT

CODE

NEXT ASSEMBLY REQ

THIRD ANGLE

PROJECTION

DO NOT SCALE THIS DRAWING

ALL OTHER CHARACT

MINOR

MAJOR

CRITICAL

PER PB B1525

CLASSIFICATION OF CHARACTER

+

+

-

-

-

+

THREE PLACE DECIMALS

TWO PLACE DECIMALS

ONE PLACE DECIMALS

0.005

0.01

0.03

TOLERANCES

UNLESS OTHERWISE SPECIFIED:

WORKMANSHIP PER PB PROCEDURE B1850

Pitney Bowes

1

3

456

2

C.O. NO. DATECHANGE DESCRIPTION

SYMLOC

This document/data record is the property of Pitney Bowes

Inc. and contains PROPRIETARY and CONFIDENTIAL information

and is not to be copied.

DWG

NO.

6.8V 5W

D2

0.22uF

C7

207-0574

453ohms

252-0564

R3

0.22uF

C8

453ohms

R4

0.22uF

C9

453ohms

R5

0.22uF

C10

453ohms

R6

0.22uF

C11

453ohms

R7

0.22uF

C12

453ohms

R8

100pF

207-0508

C3

100pF

C5

100pF

C6

100pF

207-0508

C4

MOUNTING HOLE

MH1

MOUNTING HOLE

MH2

MOUNTING HOLE

MH3

MOUNTING HOLE

LCD1

MOUNTING HOLE

LCD2

MOUNTING HOLE

LCD3

MOUNTING HOLE

LCD4

MOUNTING HOLE

KP1

MOUNTING HOLE

KP2

MOUNTING HOLE

KP3

MOUNTING HOLE

KP4

MOUNTING HOLE

KP5

MOUNTING HOLE

KP6

MOUNTING HOLE

KP7

J2 1

J2 2

J2

3

J2

4

J2

5

J2 6

J2 7

J2

8

J2

9

J2

10

J2 11

J2 12

J2

13

J2

14

WS92002

2/24/06

2/24/06

CO10343

JOG

YOUNG LEE WS

CONFIGURATION CONTROL DOCUMENT

REQUIRES UPDATING WHENEVER

THIS DOCUMENT IS REVISED

WSXX REFCCWS82002

KEYPAD

MOUNTING

HOLES

CO10343

A

12/6/05

INITIAL RELEASE

SCHEM, LCD/KEYBD 9K/1

WS9200

BOARD

MOUNTING

HOLES

LCD AND

KEYPAD

CABLE

LCD

LCD

MOUNTING

HOLES

Layout Notes:

1) C1 and C2 must be located between J2 and J1

2) C3 and D2 must be located as close as possible

to J1 with short traces

3) J1, D1 and SW1-SW6 are backside mounted parts.

See Bryce assy dwg # 30-00073-004 REV:E/B for

critical component locations.

4) MH1-3 mounting holes are plated thru 0.156"

5) LCD mounting holes are non plated 0.156"

6) KEYPAD holes are non plated 0.1"

7) Board is two layer

8) Board Layout must have all traces top side

wherever possible.

9) GND is copper pour on bottom

10) +5V is copper pour on top

11) Peel back copper pour from Key Pad carbon

trace land patterns by 1/4 inch on bottom side

12) VR1 is a top side trimpot with a screwdriver

thru slot for back side access. A .156 non plated

Thru hole must be placed under the center of the

slot for backside adjustment.

Assembly Notes:

1) 258-0372 Nylon snap fit standoff inserts

into each LED hole and #6-32 pan head

machine screws secure the LCD to the

board on the backside.

2) 258-0925 is press fits into the three PEM

board mounting holes.

Loading...

Loading...