Fuel / Exhaust

4.6

Keihin Carburetor System Overview -- Continued

Pop Off Pressure

Carburetor pop-off pressure is pre-set at the factory for a given engine. Test as outlined on following page. If pop-off

pressure is incorrect, follow the procedure below to find the cause. Pop-off pressure should not be changed to correct

a running condition problem unless required by changes in elevation, or engine/carburetor modifications for racing.

Fuel inlet needle “pop off” pressure is influenced by many factors. Atmospheric pressure, venturi vacuum (low pres-

sure), the amount of spring pressure on the control arm, fuel pressure from the fuel pump, and the size of the needle

and seat all have an affect on operating pop off pressure. All of these forces combined regulate the amount of fuel

that enters the carburetor fuel chamber and the engine.

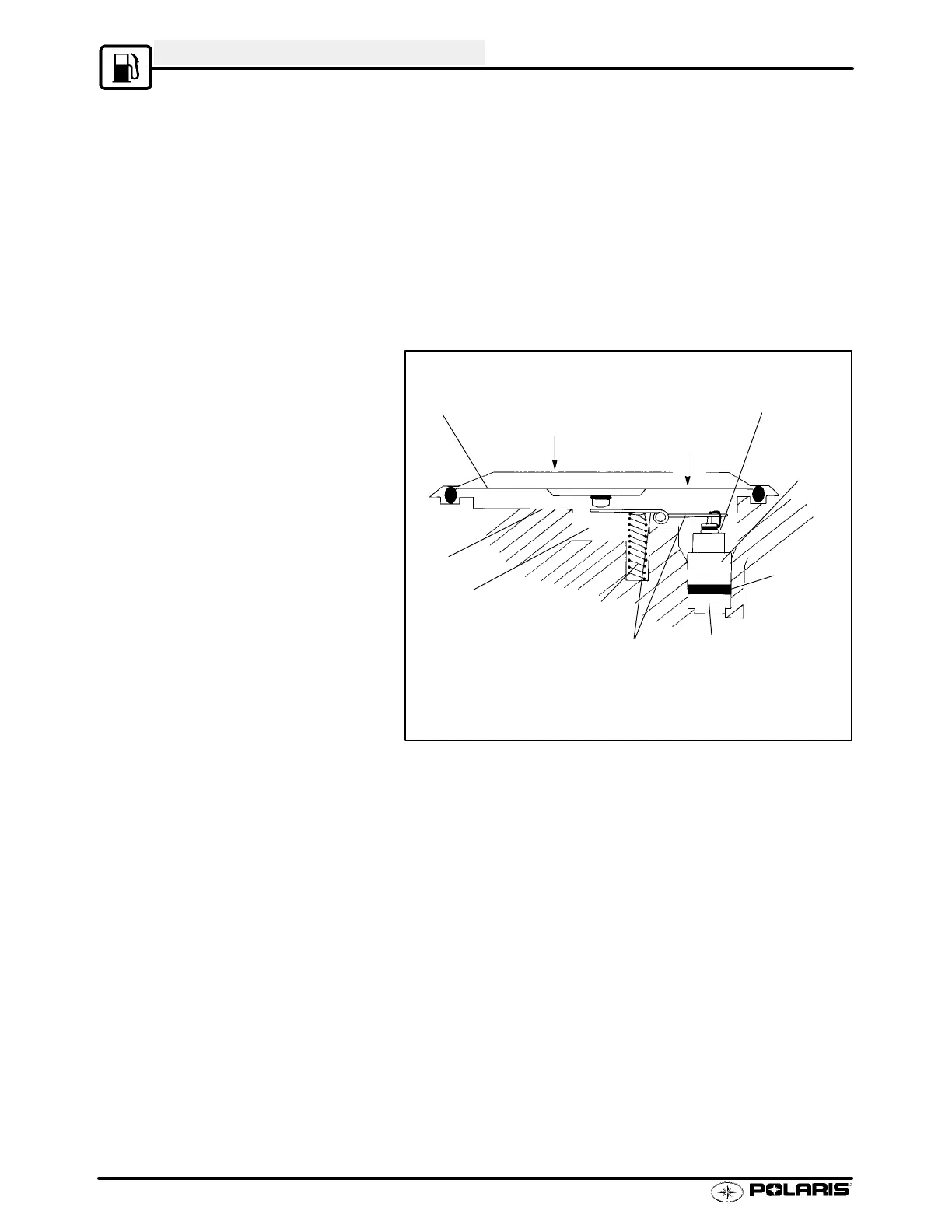

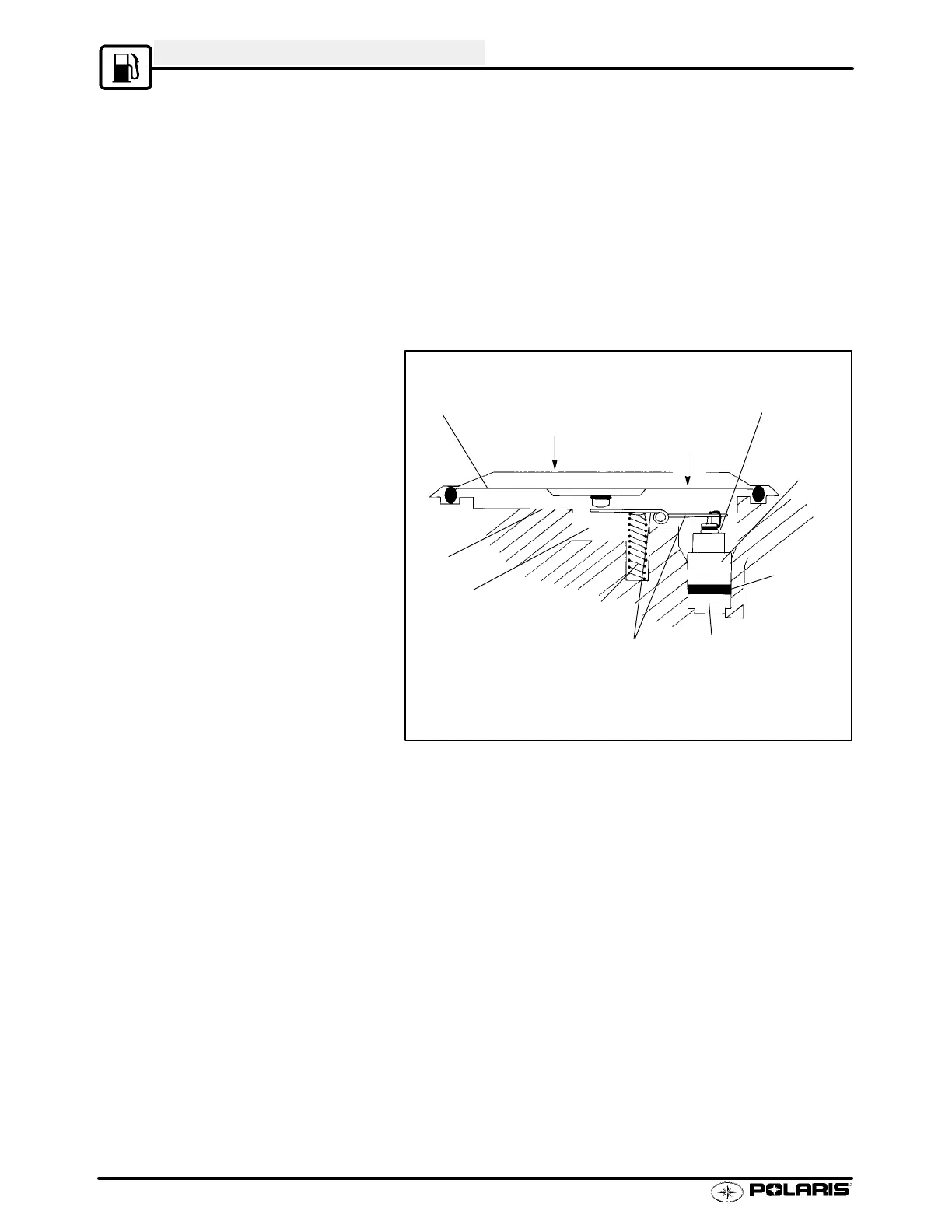

Needle Valve / Diaphragm Operation

The amount of fuel allowed into the fuel

chamber is controlled by the inlet needle

valve assembly. Opening and closing of

the valve is controlled by regulator dia-

phragm movement and spring pressure

under the control arm.

The regulator diaphragm is sealed to the

carburetor body forming two chambers.

One side is vented to atmospheric pres-

sure, the other side (fuel chamber) is con-

nected to the venturi via the jets and pas-

sages. Atmospheric pressure pushes on

one side of the diaphragm, applying pres-

sure on the control arm in the fuel chamber.

This reduces pressure on the inlet needle

and allows it to lift more easily off the seat.

When the engine is running, pressure in the

carburetor venturi (and therefore the fuel

chamber) is less than atmospheric. This in-

creases the effect of the atmospheric pres-

sure on the diaphragm and lever . When re-

turn spring pressure is overcome by these

forces, the needle lifts off of the seat or

“pops off”, allowing pressurized fuel to enter

the fuel chamber.

Pop off pressure cannot be tested with the engine running. However, a static pressure test can help identify prob-

lems within each individual carburetor.

The measurement indicates the amount of pressure required to force the fuel inlet needle off of the needle seat

without the engine running. Thoroughly inspect all system components whenever a rich or lean condition is en-

countered.

NOTE: If inlet needle does not seal properly , fuel may enter the engine and cause flooding when the engine is off.

Low pop off pressure may be caused by:

S Foreign material in the tip of the needle or needle seat

S Worn, broken, or damaged lever arm return spring

S Leaking needle seat O-Ring

S Corrosion on lever arm, lever arm pin, and/or return spring

S Incorrect lever arm return spring (Use only genuine Polaris parts)

S Fuel return line kinked or return restrictor orifice plugged (in carburetors or in return line)

1

Regulator

Diaphragm

Return

Spring

Fuel

Chamber

Fuel Inlet

(Fuel Pressure)

(V enturi

Low Pressure)

Inlet Needle

Inlet

Needle

Seat

Sealing

O-Ring

Vent-

Atmospheric

Pressure

Diaphragm

Cover

Control Arm

Loading...

Loading...