Apply Marine Grade

Silicone Sealant PN

8560054

Final Drive / Propulsion

5.21

Pum p Alignm ent

NOTE: Checking the pump alignment is not required if the alignment is not suspect. You need only to verify align-

ment if alignment is determined to be incorrect. Symptoms of incorrect pump alignment are, but not limited to:

stripped driveshaft, stripped coupler splines, broken engine mounts, and unevenly worn driveshaft, and worn

bearing carriers.

1. If pump housing was removed, begin by re--attaching

to the hull. Refer to pages: 5.3 and 5.4 for bolt torque.

2. Disconnect lanyard cord lock plate from engine stop

switch. Remove battery negative cable.

3. Remove impeller and stub shaft from pump housing.

Inspect bearings for wear or damage and replace if

necessary. See Stator Disassembly/Inspection this

section.

4. Assemble pump without stub shaft, impeller, or tail

cone.

5. Install stator housing to pump housing. Tighten

mounting bolts to 18 ft. lbs. (24.8 Nm).

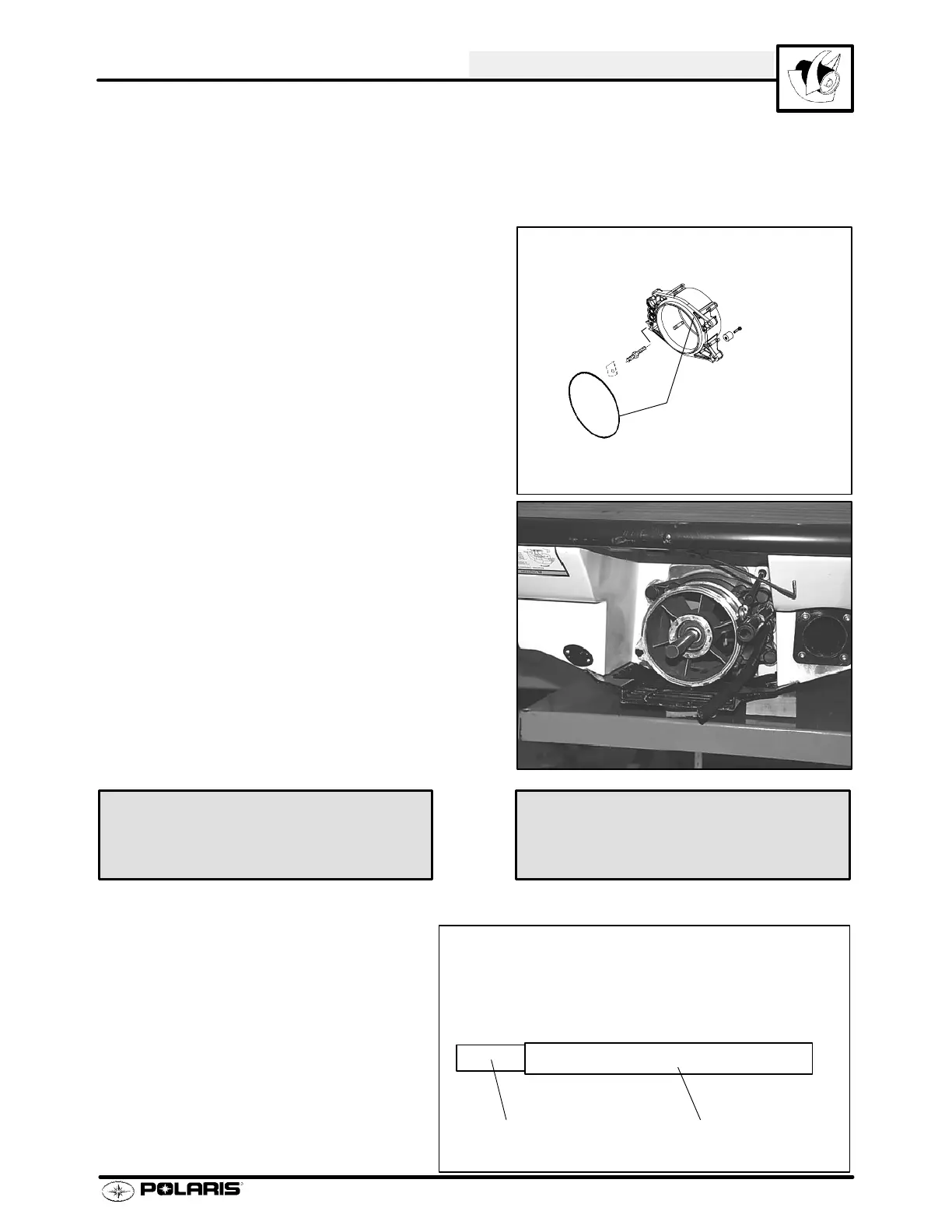

6. Install alignment tool into pump bearing housing with the smaller diameter coupler end facing toward engine.

7. Slide coupler end of alignment tool into

drive coupler.

8. If engine and pump are properly aligned,

the tool will slide freely into the engine

coupler .

9. If mis-alignment is evident, determine the

probable cause of misalignment from the

following chart and correct the condition.

Alignment Tool PN 2871343

Stator Housing Mounting Bolt

Torque -- 18 ft. lbs. (24.8 Nm)

W atercraft Engine/Pump Alignment Tool PN 2871343

Coupler end -

small diameter

Pump end -

large diameter

Loading...

Loading...