Final Drive / Propulsion

5.26

Bea ring Housing Rem oval / Inspection -- Continued

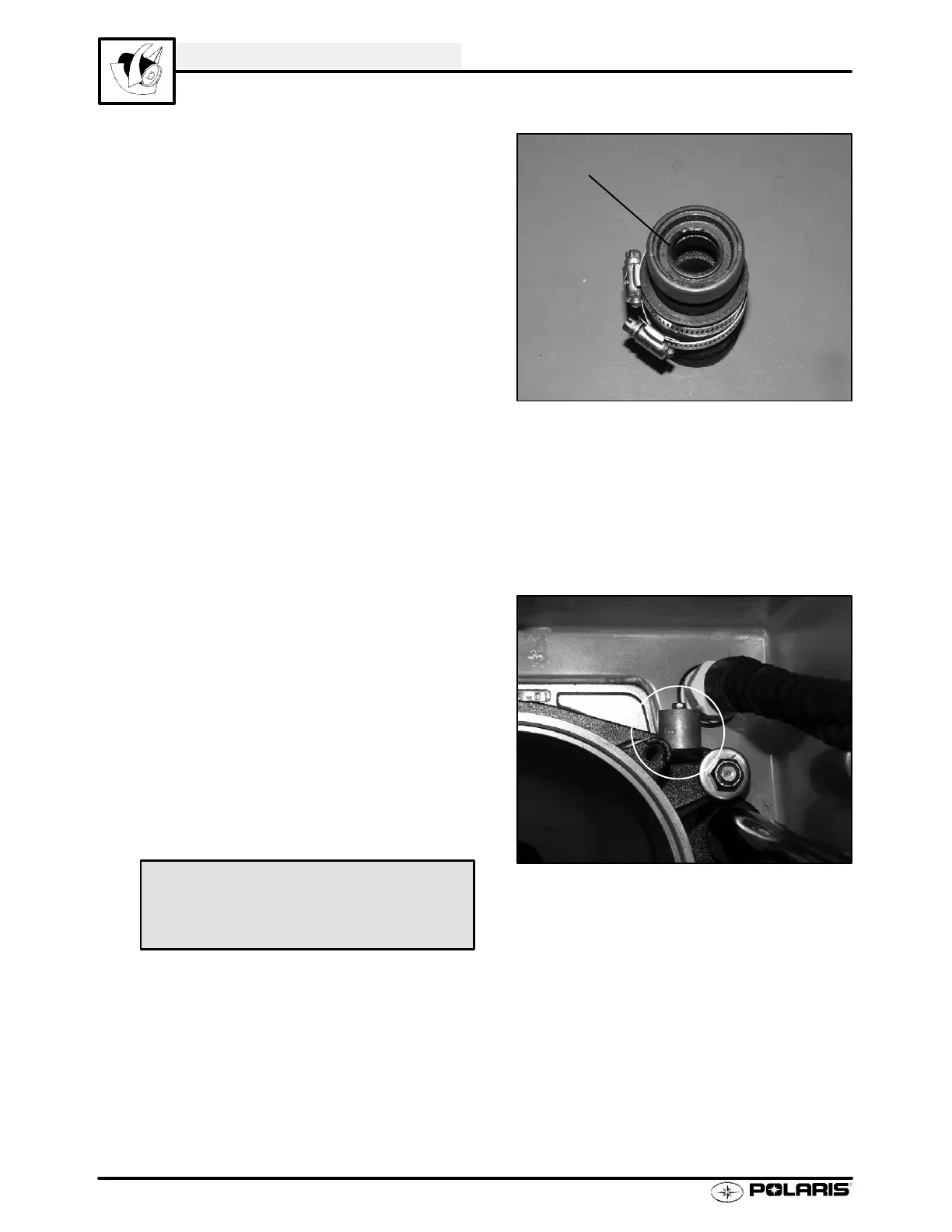

2. Inspect bushings and seals in bearing housing

assembly for wear or damage that may allow water

to leak into hull. The housing cannot be rebuilt.

Replace as an assembly if wear is evident.

3. Check sealing and bearing surface on driveshaft

for wear, nicks or damage that may accelerate seal

or bushing wear.

Sa cri ficial Anode

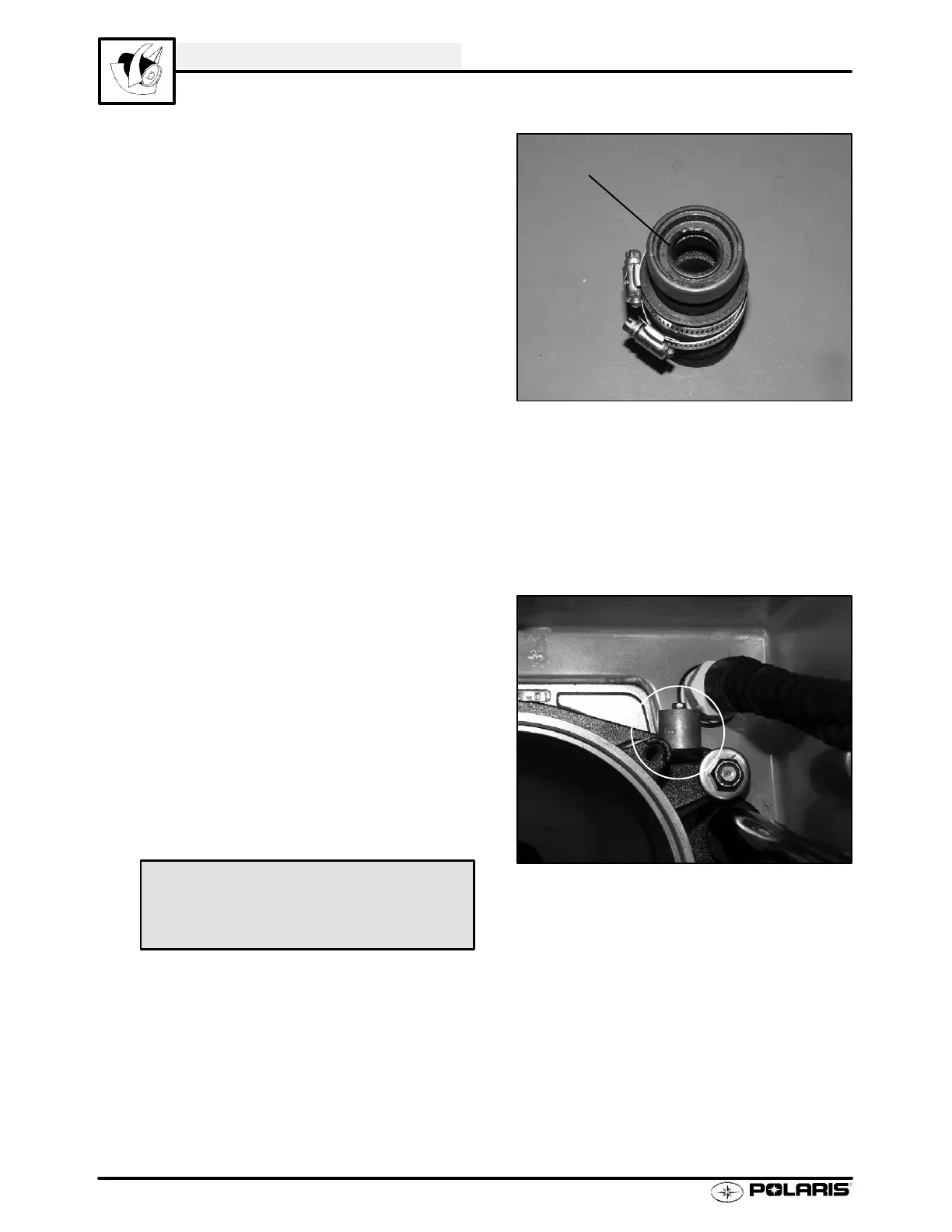

A zinc sacrificial anode is in place on all models on the pump housing. The purpose of the anode is to prevent

corrosion of metal parts due to electrolysis. The mounting surfaces must be clean and the mounting bolt tight

to maintain a good connection between the pump and anode.

1. Periodically inspect anode for excessive wear.

2. Check bolt to be sure it is tight. If the bolt is loose,

remove anode and clean mounting surfaces on pump

and anode.

3. Apply dielectric grease to bolt threads and contact

surfaces.

4. T ighten bolt securely.

NOTE: During preventative maintenance, verify that

the anode is tightened securely to the pump housing.

Replace sacrificial anode whenever anode shows

signs of erosion.

Inspect

Sacrificial Anode Bolt Torque

25in.lbs. (2.9Nm)

Loading...

Loading...