Maintenance

2.13

Electrical Components -- Continued

Spark Plugs

1. Disconnect high tension leads and remove spark

plugs.

2. Inspect electrodes for wear, carbon buildup, or

fouling (wet oily residue). Replace plugs if edges of

electrodes are rounded or eroded.

CAUTION:

Severe engine damage may occur if the incorrect spark

plug is used. Refer to spark plug gap chart in this page for

spark plug type.

3. Clean with electrical contact cleaner or a glass bead

spark plug cleaner only. A wire brush or coated

abrasive should not be used.

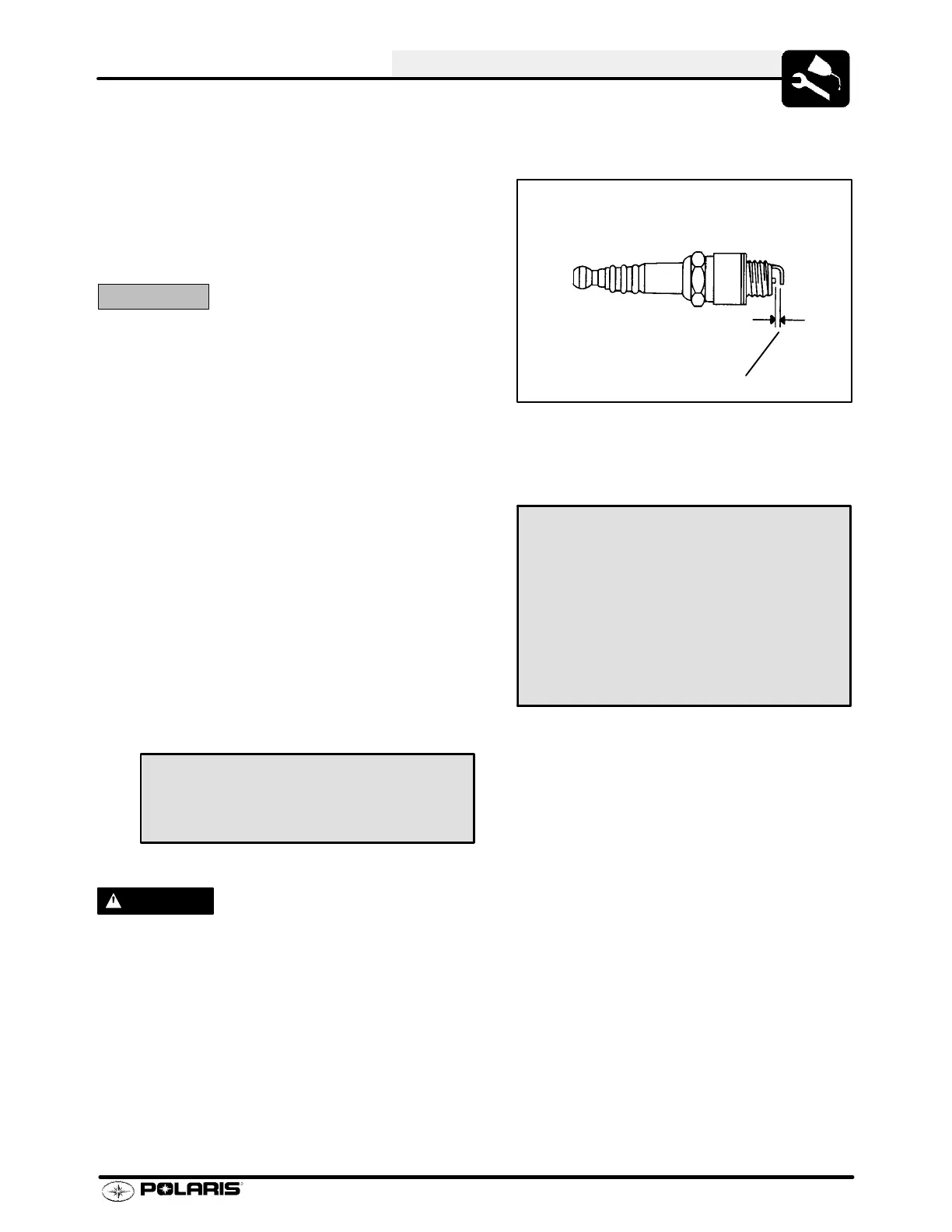

4. Measure gap with a wire gauge and refer to

specifications. Adjust if necessary by bending the

side electrode carefully.

5. Coat spark plug threads with a small amount of

anti-seize compound.

6. Install spark plug and torque to 18ft.lbs.

7. Make sure spark plug caps are screwed completely

onto end of plug wire.

8. Apply a small amount of Nyogelt grease to inside of

plug caps and install.

9. Push cap onto plug until cap “snaps” into place.

WARNING

Use only RESISTOR TYPE spark plugs.

Ignition Timing Specifications

Refer to Electrical Section for ignition timing adjustment procedure and timing chart.

Spark Plug Gap

Spark Plug Gap

2002 700 LE Engines: NGK BR8ES

Gap: .024 -- .028 in. (.6 -- .7mm)

2002 1200 Carb Engines: NGK BR9ES

Gap: .024 -- .028 in. (.6 -- .7mm)

2002 DIt Engines: NGK PZFR6H

Gap: .028 -- .032 (.7 -- .8mm)

Nyogelt Grease

PN 2871329

Loading...

Loading...