Final Drive / Propulsion

5.17

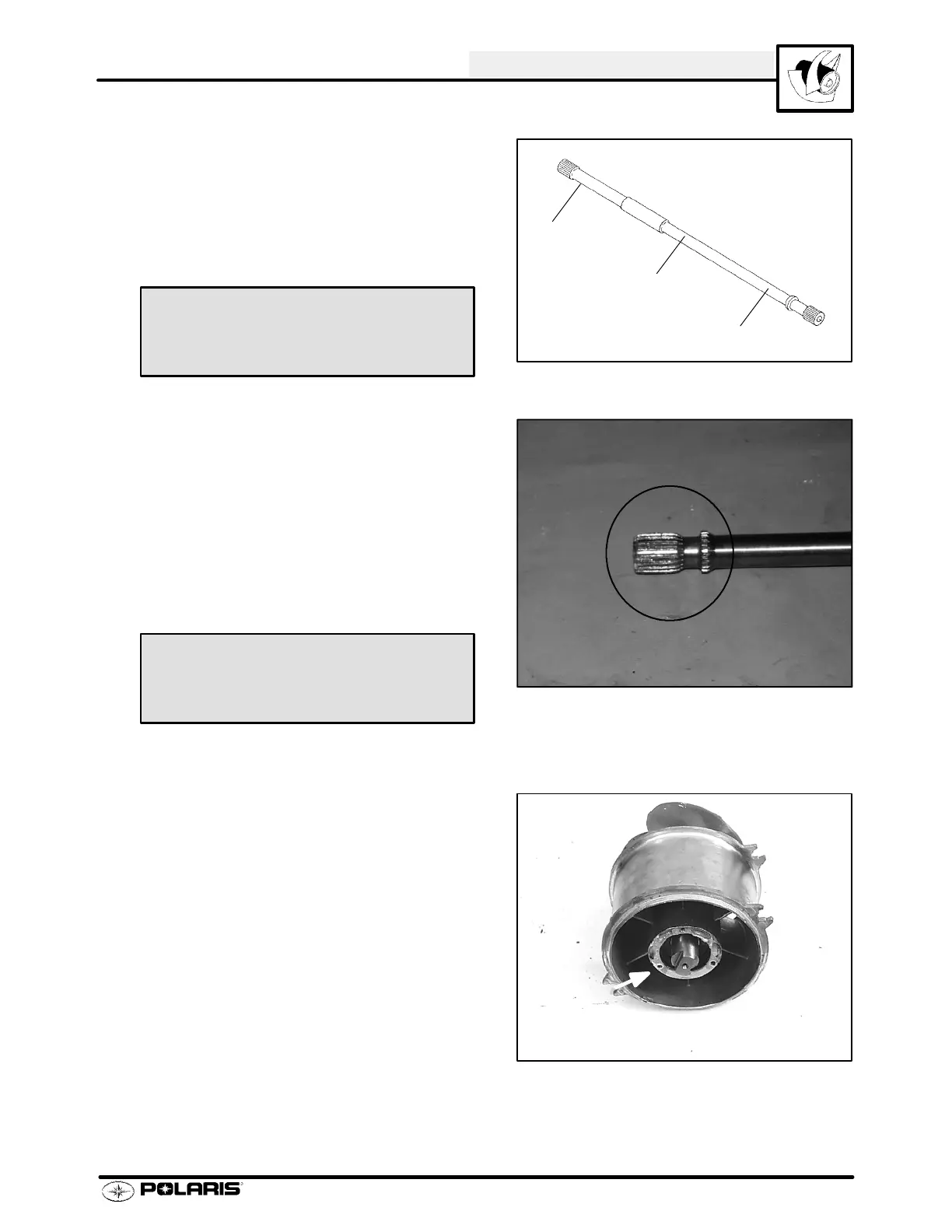

Drive Shaft Inspection

1. Clean driveshaft and support in V - blocks as shown

(C). Measure runout by rotating shaft and

observing dial indicator at point (B). Replace if

runout exceeds the service limit.

NOTE: Excessive driveshaft runout can cause vibra-

tion, bearing, and spline failure. See Pump/Final Drive

T roubleshooting at the end of chapter 2.

2. Inspect driveshaft splines and splines inside engine

drive coupler and impeller carefully for wear or

damage. Replace worn parts. Rubber bumpers

control driveshaft end play. Replace if worn,

cracked or damaged.

NOTE: If drive shaft, impeller , or coupler splines are

worn or damaged, improper pump-to-hull, or pump-to-

engine alignment should be suspected. Refer to Pump/

Drive shaft Alignment on pages 5.12 -- 5.14 for more in-

form a ti o n .

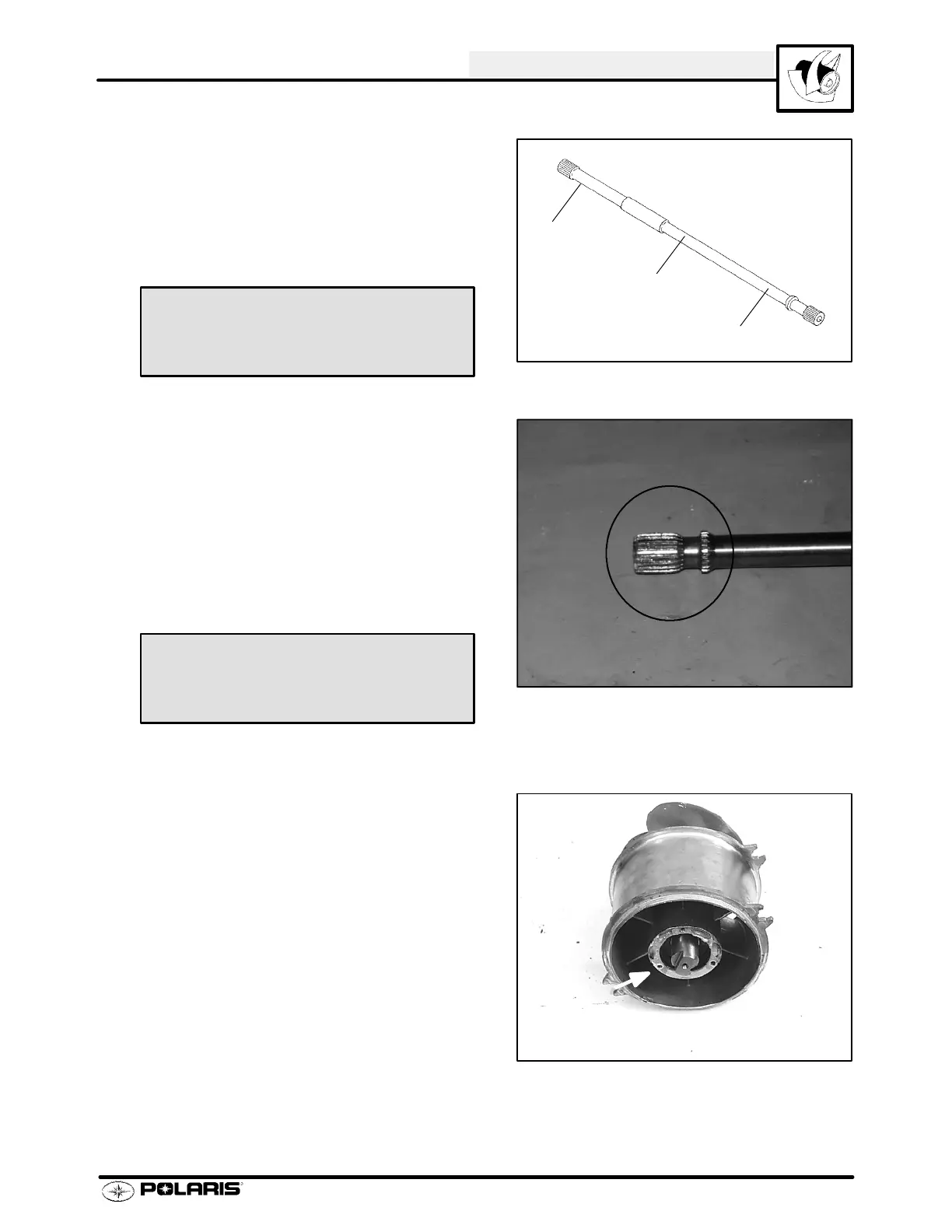

Stator Disassem bly

1. Remove tail cone screws (3) and tail cone. Inspect

O--ring seal located behind tail cone. Replace seal if

damage is evident.

NOTE:

When removing tail cone, hold stator with cone pointed

down. Twist cone off. This will allow any water from enter-

ing the impeller assembly. It is normal for a small amount

of water to be inside the cone during operation.

C

B

C

Place dial indicator

at (B)

Support in V-blocks

at (C)

Drive Shaft Runout

Service Limit: .005² (.13mm)

Drive Shaft End Play

.100-.200² (2.54-5.08mm)

Loading...

Loading...