Final Drive / Propulsion

5.16

Pump Assembly / Installation -- Continued

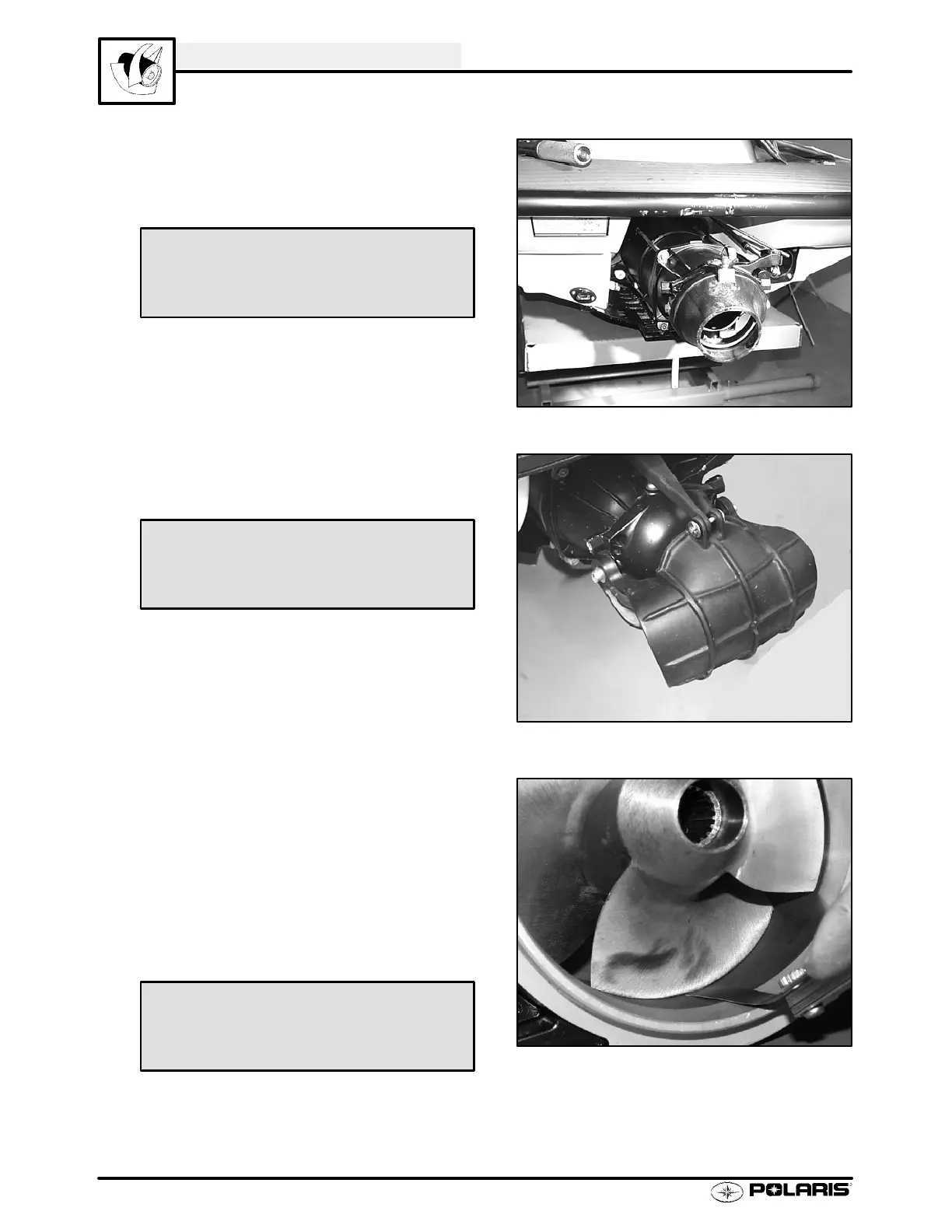

8. Attach steering linkage to steering nozzle. Tighten to

specifications.

9. Attach bilge siphon hose(s) to pump assembly. Use

panduit strap to secure hose(s).

10. Using a grease gun, grease bearing carrier. Reinstall

the coupler shroud. Tighten clamp to 35 in.lbs.

11. Attach reverse gate to reverse linkage with new cotter

pin. Bend ends of cotter pin in opposite directions. If

secured by bolt, tighten to specifications.

Impeller Clearance

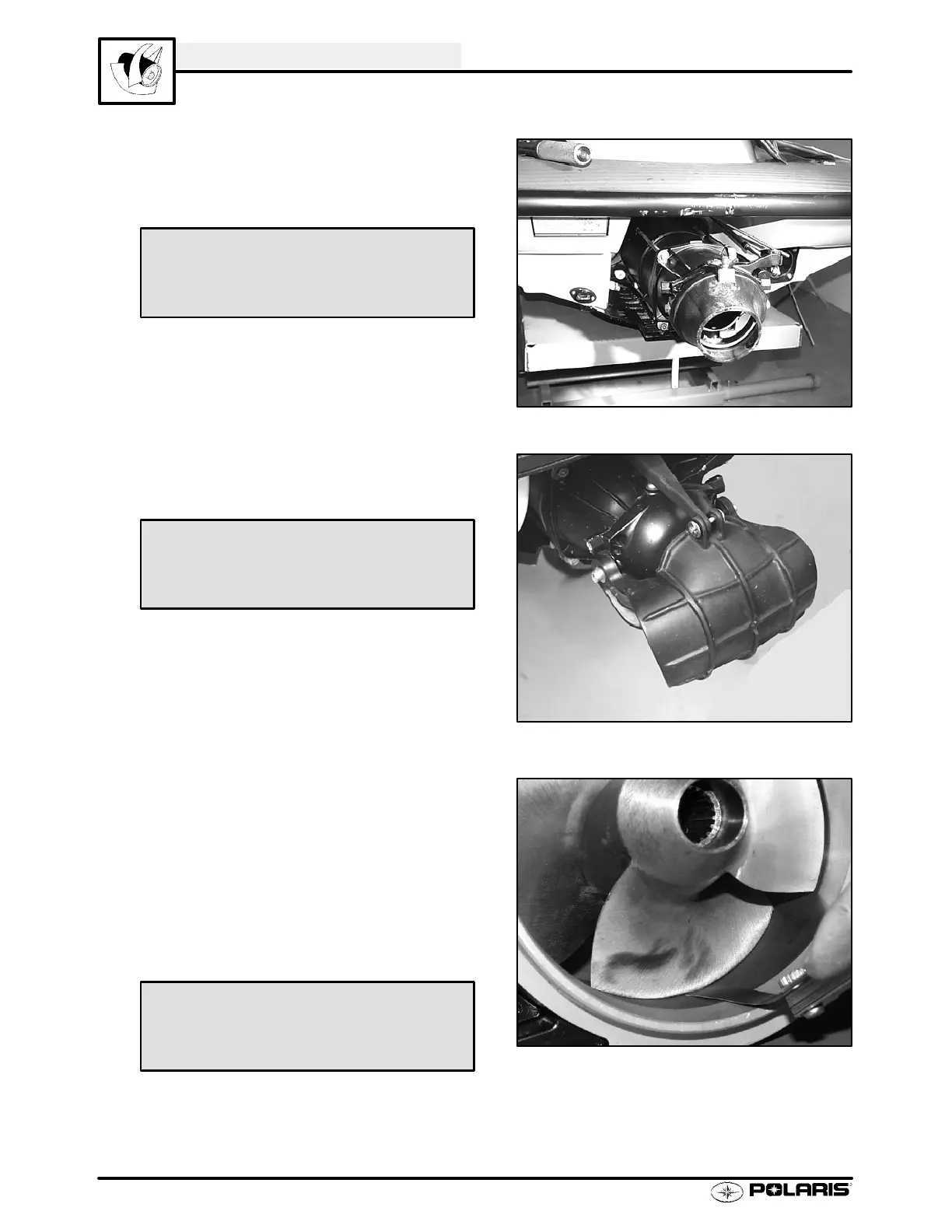

1. Remove lanyard cord and lock plate from engine

stop switch. Disconnect battery ground (--) cable.

2. Remove intake grate and check impeller to housing

clearance with a feeler gauge. Measure clearance

at leading edge, middle, and trailing edge of each

blade. Replace impeller if clearance exceeds

service limit at any point. If clearance exceeds

service limit with a new impeller , replace pump

housing.

Steering Nozzle Bolt Torque

8ft.lbs. (11Nm)

Reverse Nozzle Bolt Torque

14 ft.lbs. (19 Nm)

Impeller Clearance

Std: .002 - .008² (.05 -.20 mm)

Service Limit: .020² (.5 mm)

Loading...

Loading...