Fuel / Exhaust

4.34

Mixture Screw Adju stment an d Tuning

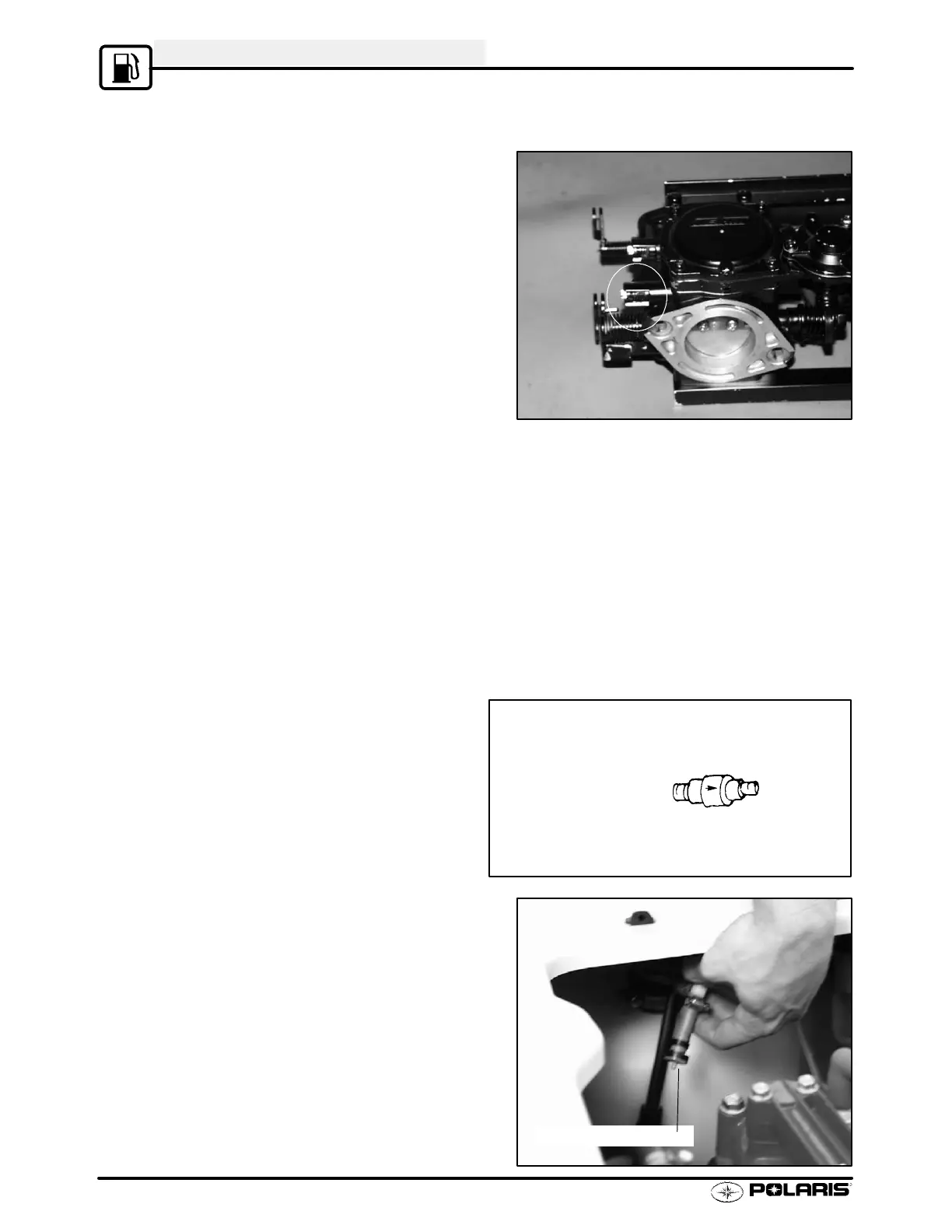

1. The low speed mixture screw is located

lowermost on carburetor. Remove limiter cap

(pull outward).

2. With craft in the water or test tank, adjust idle

speed to specifications (see procedure this

section).

3. Start engine, let it idle for one minute to normalize

engine temperature. Rev engine slightly for 10-20

seconds and return to idle.

4. T urn each mixture screw to obtain highest idle

RPM.

5. T urn each screw out approximately 1/4 turn from

this point. Fine tune to achieve best throttle

response.

Fuel Tank Vent Operation

The fuel tank vent system consists of an inlet check valve and a pressure relief valve. The inlet check valve allows

air to enter the tank as the fuel supply is being used. The pressure relief valve maintains a 1-1.5 PSI positive

pressure in the fuel tank. If pressure in the tank exceeds 1.5 PSI, the valve releases and excess pressure is al-

lowed to escape.

Inspection

The check valves can be tested for proper operation by applying pressure to one end with the Mity Vact. Apply

approximately 5 PSI to the end of the valve marked VAC. The valve should hold steady pressure. Try to apply

pressure to the other end of the valve, it should allow air to go through easily with no pressure build up. Replace

the check valve if found to be faulty.

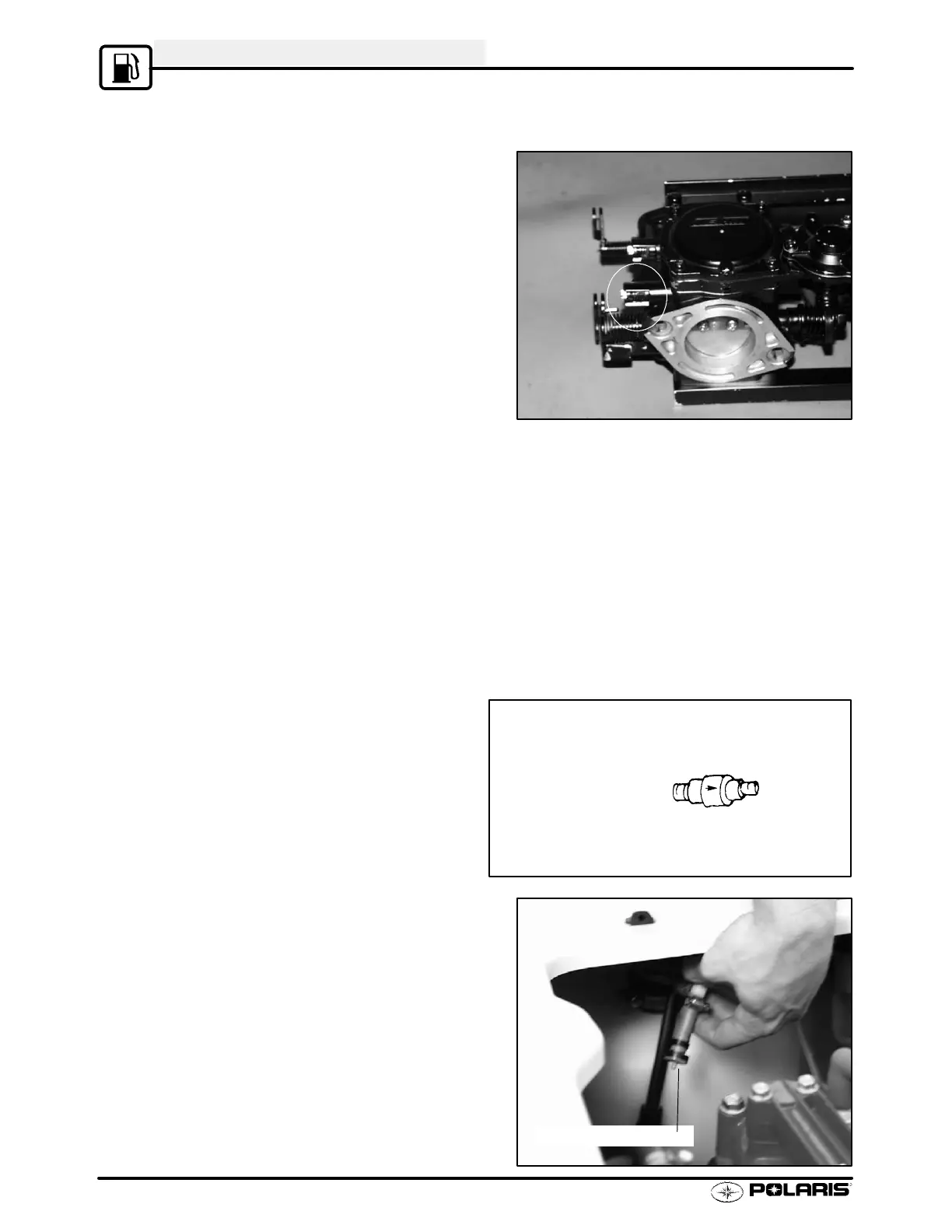

Relief Valve Testing

Apply air pressure with a Mity Vact to relief valve.

With air pressure applied in the direction of the ar-

row, the valve should “pop” between 1.0 and 1.5

PSI. In the opposite direction it should hold pres-

sure.

Fuel Tank Check Valve Testing

To test the air inlet check valve, remove the valve

and apply approximately 5 PSI pressure to the end

of the valve marked VAC. The valve should hold

steady pressure. Connect the tester to the other

end and apply pressure. Air should pass through

the valve with no pressure build up. Replace the

check valve if it holds pressure both ways or fails

to hold pressure one way.

Relief Valve

Apply 1 - 1.5 PSI

Air Inlet Check Valve

Loading...

Loading...