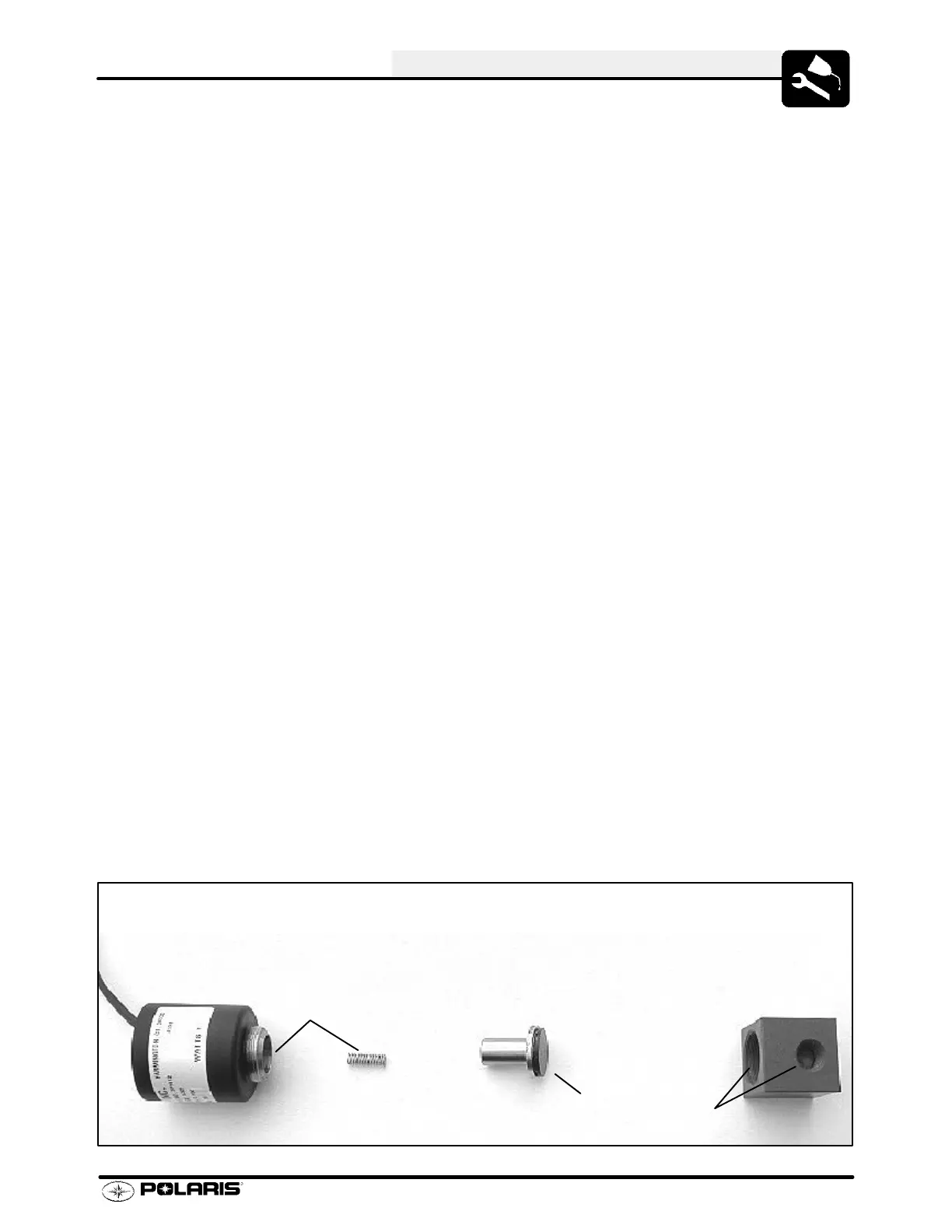

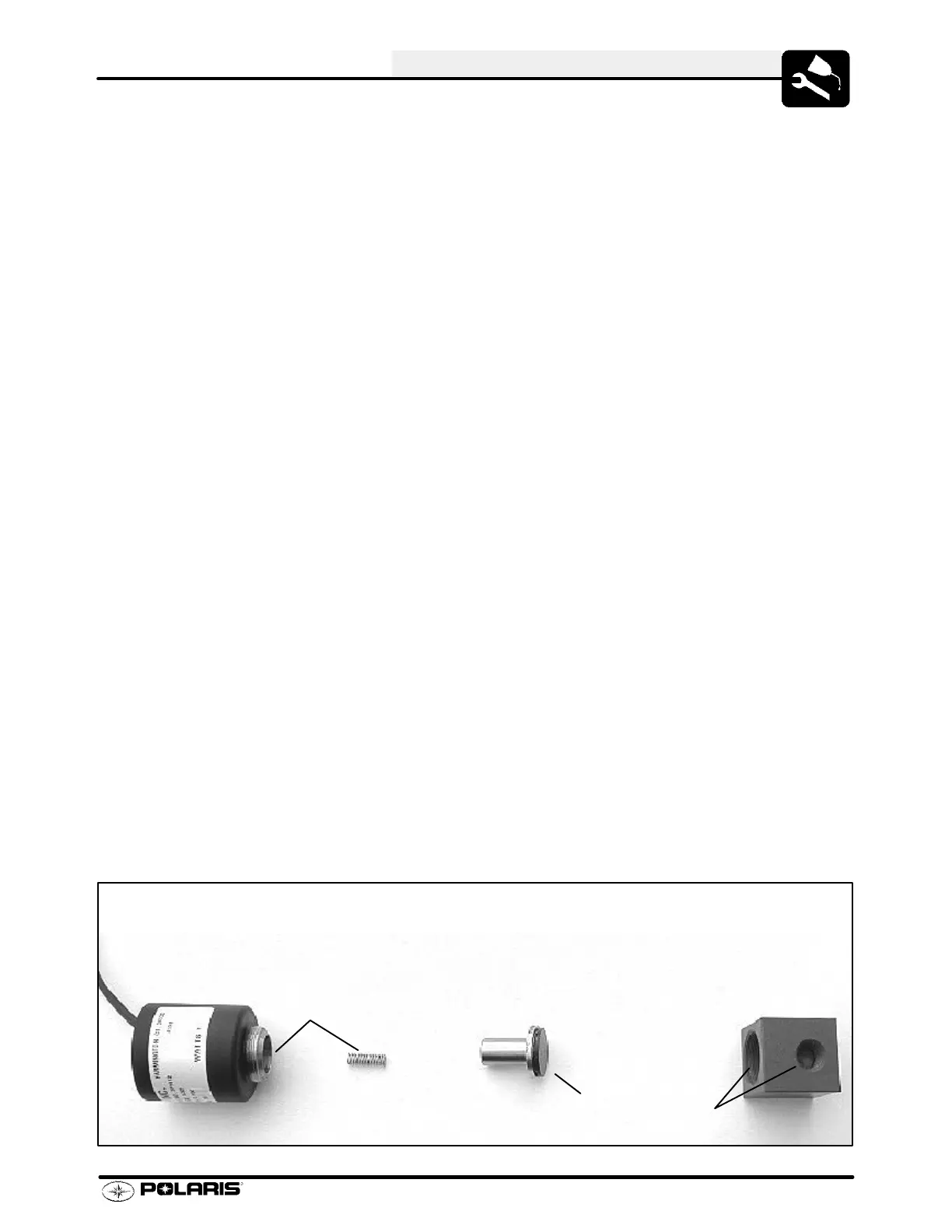

Solenoid

Plunger Spring

Plunger Assembly

Square Valve

(One side marked

“IN”; Opposite side

marked “OUT”)

Clean

Clean

Clean

Order of Assembly

Maintenance

2.15

Engine -- Continued

Cylinder Head Re -Torque*

With engine at room temperature (68° For20° C), re-

torque cylinder heads in a criss-cross pattern de-

scribed in the Engine Section.

Cylinder Base Gasket Re-Torque*

With engine at room temperature (68° For20° C), re-

torque cylinder base nuts following the pattern de-

scribed in the Engine Section.

Exhaust Manifold*

With engine at room temperature (68° For20° C), re-

torque exhaust manifold bolts following torque pattern

shown in Engine section.

NOTE: *Refer to Preventative Maintenance Schedule on Pages 2.2 and 2.3.

Water Injectio n Solenoid Maintenance -- (Virage i Only)

Inspect and clean the water injection solenoid at 25 hour intervals and during pre and post season inspections

or when watercraft is operated close to shore for extended periods of time. The solenoid must be cleaned after

any operation in water that is saturated with sand, salt, algae weeds, etc. Failure to do so may cause poor engine

performance.

1. Begin by disconnecting the solenoid--to--harness wiring connector.

2. Loosen and remove the gear clamp from the exhaust pipe fitting. Remove the hose from the fitting.

NOTE: Take care not to loose any parts when disassembling the solenoid valve.

3. Remove the solenoid by grasping square valve assembly and turning solenoid counter--clockwise. Use

extreme care if tools are required to loosen solenoid.

4. Inspect the IN and OUT ports on the square valve, the plunger assembly, spring, and solenoid barrel for sand,

debris, algae, etc. Remove any debris and clean components thoroughly.

W ARNING: Do not remove the rubber gasket from the plunger .

5. Reassemble components in reverse of disassembly. V erify threads are clean. Firmly tighten the solenoid to

square valve. Re--attach hose to pipe fitting and reconnect wiring harness. Tighten gear clamp to 22 in. lbs.

Loading...

Loading...