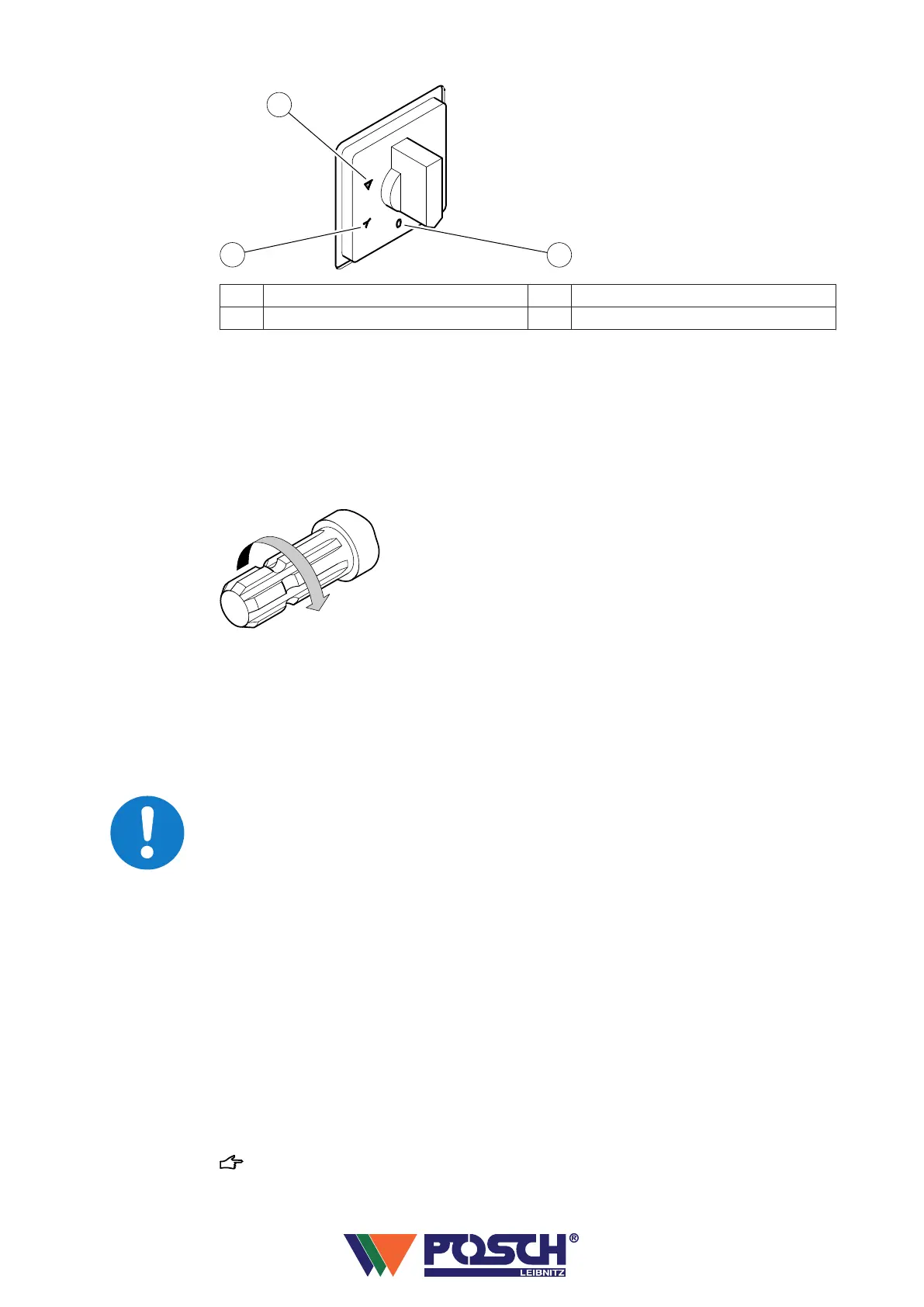

1 Neutral position 3 Delta position

2 Star position

If the electric motor will not start (red light for rotational direction detection is on):

Procedure as for type 1.

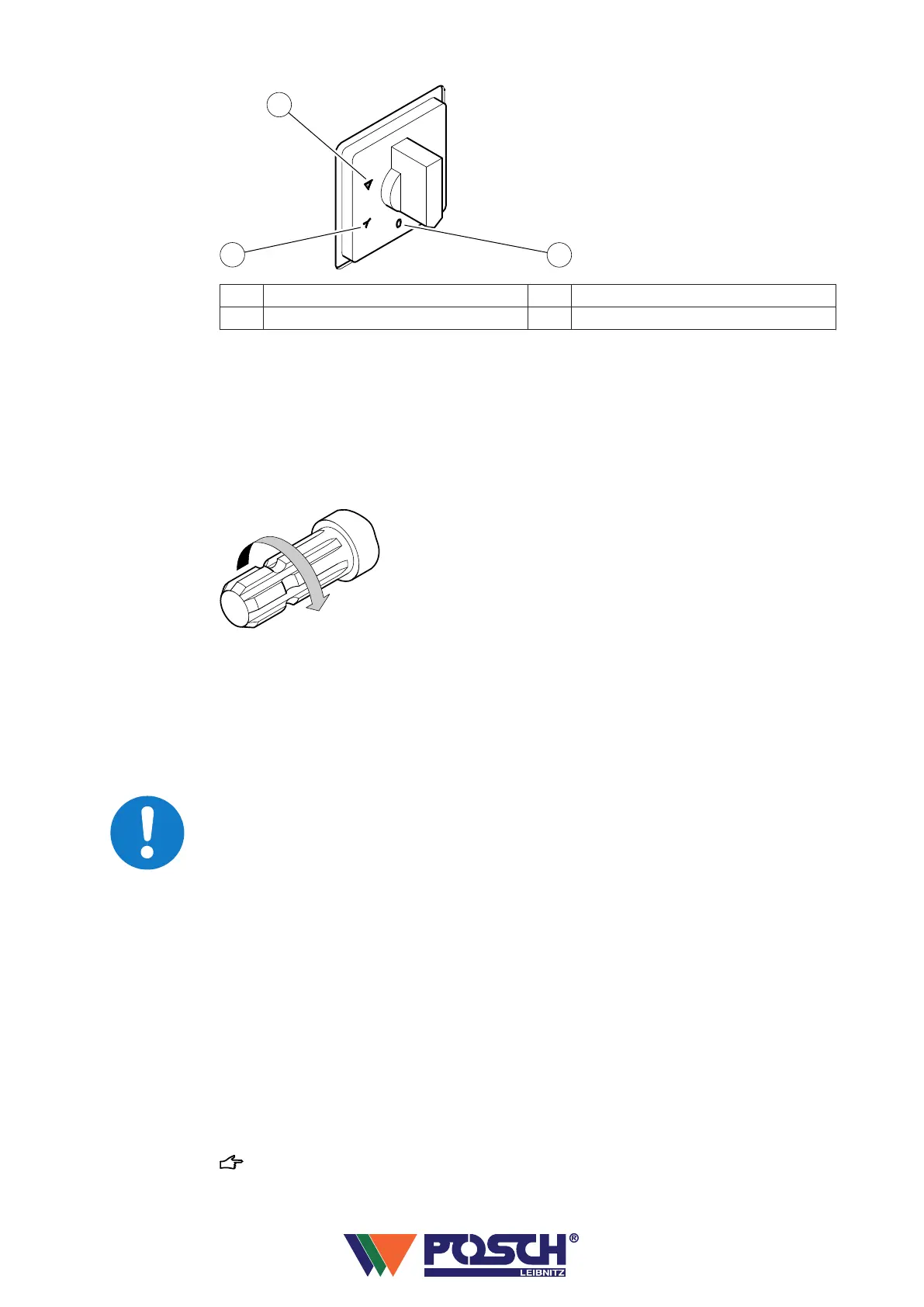

Driven by tractor via cardan shaft (type Z)

▪ Attach the universal joint shaft and secure with the safety chain.

▪ Clockwise rotation of the tractor PTO shaft.

▪ Turn the tractor's manual throttle to minimum.

▪ Slowly engage the tractor PTO shaft and allow the machine to start moving.

▪ Set the required PTO shaft speed using the manual throttle.

Maximum PTO shaft speed:

▪ 480 rpm

The maximum PTO shaft speed must on no account be exceeded, otherwise the oil will

become too hot. This leads to premature wear and leaks in the pump, cylinder and hydraulic

pipes.

Before disengaging the universal joint shaft, set the manual throttle of the tractor to

minimum.

The universal joint shaft must be stored in the universal joint shaft linkage when it is

disconnected.

Model S (higher speed)

With a PTO shaft speed of 300 - 540 rpm, operation of the tractor is efficient, with low fuel

consumption and less noise pollution.

For a short-term increase in efficiency up to a maximum of 2 hours of continuous operation,

the machine can be operated with a PTO shaft speed of 650 rpm to achieve the maximum

splitting speed.

▪ A maximum of 2 hours without a break for the series production machine

▪ Continuous operation for machines with an oil cooler (option C)

For machines with a rope winch (option W), operation is only permitted with a PTO

shaft speed of 540 rpm maximum.

4.2

4.2.1

Start-up

17

Loading...

Loading...