DESCRIPTION OF PROGRAMMING PARAMETERS

4.7. Group 7 – G7: Start / Stop Mode Configuration

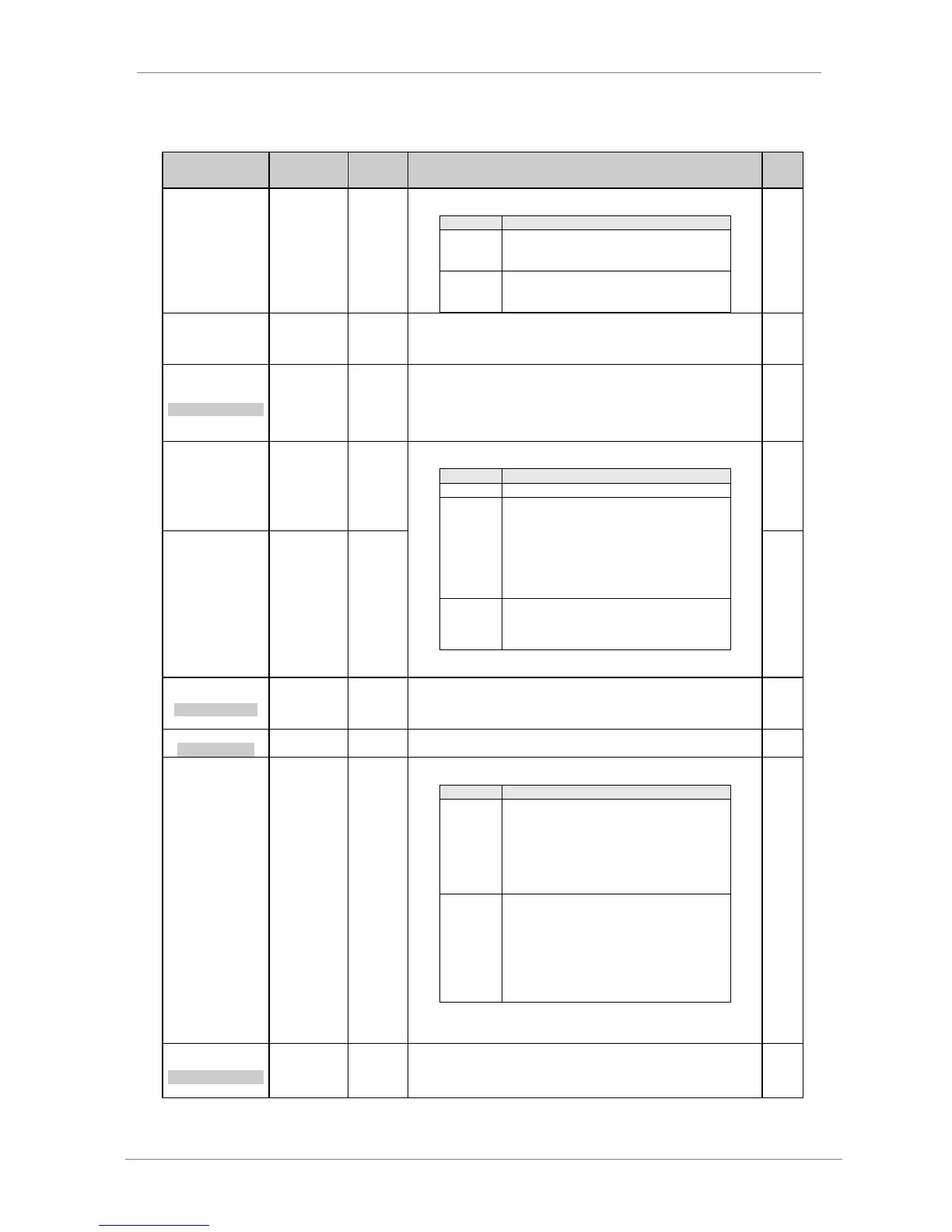

Parameter /

Default Value

It selects the main stop mode of the drive. This value should be configured

appropriately for each application.

The drive will stop applying a frequency ramp to

stop the motor. The rate of stop is determined in

screen 'G5.2 Decel 1'

The drive will turn off the output to the motor. The

motor sill coast to stop. Stopping time is

determined by system inertia.

User can select an alternative stop mode of the drive if required. This value should be

set for each application. For options information see parameter „G7.1 STOP 1=RAMP‟.

Note: Stop mode 1 or 2 can be selected by digital inputs, by comparator output

functions, or by setting a changing speed for stop mode in 'G7.3 BRK STP 2'.

3 BRK STP 2 = OFF

STP2 UNDER SPEED

G7.3 / Changing

speed for stop

mode

When this parameter is set to a value other than zero a second stopping profile can be

activated based on motor speed. When the drive receives a stop mode 1 command, it

will stop from steady status to the speed set here. At that moment, the drive will apply

stop mode 2 to complete the stop.

Note: Stop mode 1 or 2 can be selected by digital inputs, by comparator output

functions, or by setting a changing speed for stop mode in 'G7.3 BRK STP 2'.

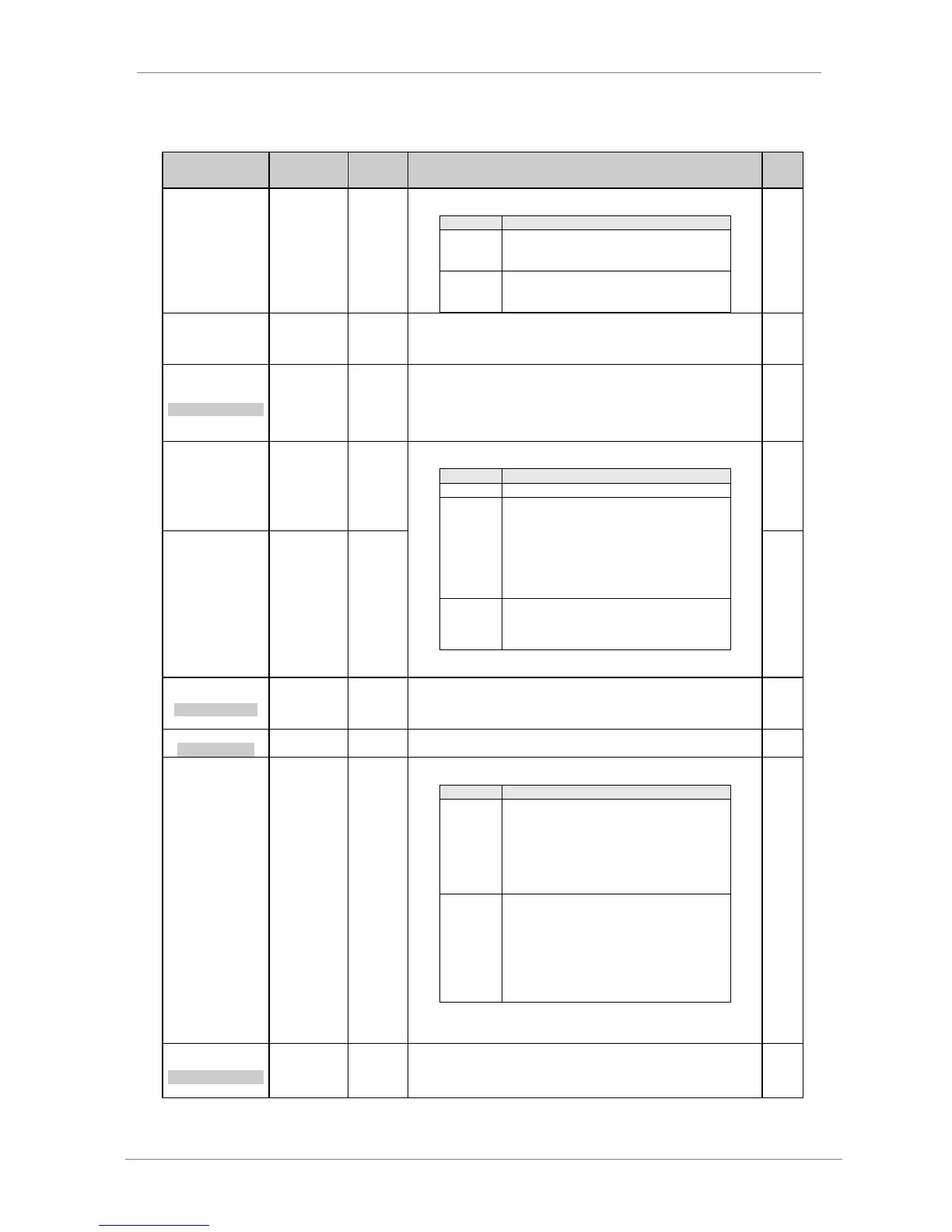

It selects the start mode of the drive. This value should be configured

appropriately for each application.

Drive will start applying a frequency ramp to the motor.

In this mode, the motor shaft speed is automatically

searched for and the frequency output of the drive is

set to match the actual motor speed. From this point

the motor is then accelerated normally up to the

reference speed. This allows starting loads that are still

rotating when the drive receives a start command.

Note: This option is valid when the motor is running at

positive rotation direction.

Operates similar than the option „SPIN‟. The difference

lies in the possibility of starting loads that are still

rotating independently of the rotation direction of the

motor.

Note: Start mode 2 (alternative start mode) is selected through a digital input

configured with option ‟22 START MODE 2‟.

6 STAR DLY = OFF

DELAY TO START

Allows setting of a delay time from the moment the drive receives the start command to

the beginning of providing an output frequency to the motor.

Note: After receiving the start command, the drive will wait until the delay time is

elapsed. During this time, the drive status will change to „DLY‟.

7 STOP DLY = OFF

DELAY TO STOP

Allows setting of a delay time applied from the moment the drive receives the stop

command until the drive stops providing an output frequency to the motor.

G7.8 / Minimum

stop speed

Allows user to stop the motor when the speed is below the SD700FR lower speed

limit.

In this case, the motor will continue to operate at

minimum speed defined as minimum speed limit

(set in G10.1 or G10.3), even if the speed

reference is below these settings. For example, if

„1 MIN1 SP=+30.00%‟, and the speed reference

is +20.00%, the equipment will operate at

+30.00%, and never below this value.

In this case, the drive will automatically start when

the speed reference is above the value set as

minimum speed limit. While the speed reference

is below this value, equipment will be in 'READY'

status.

If the drive is decelerating and the reference is

below the minimum speed value, then the

equipment will stop by spin.

Note: If you want to stop the motor when the reference is below a fixed speed

setpoint, you should set this parameter to YES. Additionally, you should set the

correct values in 'G10.1 MIN1 SP' or 'G10.3 MIN2 SP'.

9 OFFdly = OFF

DELAY AFTER STOP

G7.9 / Delay time

between stop

and next start

Allows setting a delay time between the moment the drive has stopped and the

next starting. The next time the drive has to start it will consider no additional

delay time unless parameter „G7.6 START DLY‟ had been set to a value different

from OFF.

Loading...

Loading...