flow to the Nozzle. At the same instant a portion of the oil

bypasses the Nozzle through the adjustable low fire regulating

valve, reducing the pressure at the Nozzle as required for low

fire rates. When the low fire flame is proven by the flame

detector*, the Return Oil Solenoid Valve (7) is deenergized,

putting full high fire pump pressure on the Nozzle. Simulta-

neously, the Three-Way Solenoid Valve (10) is energized,

allowing oil into the Hydraulic Cylinder (9) which mechanically

drives the Air Damper Arm (13) to the high fire position. The

burner operates at full high fire until the system demand is

satisfied. Refer to page 31, Table 8 or page 34, Table 9 to

determine nozzle return flow pressure and flow rates. This

depiction shows the Air Dampers and Hydraulic Cylinder at the

low fire light off position.

The Low-High-Low system is identical to the Low-High-Off

system, except that an additional pressure or temperature

controller is added to the system, which at a selected preset

point will electrically switch the burner to either the high or low

fire position. When the burner is running at high fire and the

controller calls for low fire, the normally closed Oil Solenoid

Return Valve (7) (closed at high fire) is energized, reducing

nozzle pressure to the low fire rate. Simultaneously, the Three-

Way Solenoid Valve (10) is de-energized, allowing oil to flow

out of the Hydraulic Cylinder (9) back to the Pump and driving

the Air Dampers (4) to the low fire position. Responding to load

conditions, the burner can alternate indefinitely between the

low and high fire positions without shutting down. When system

load demand is satisfied, all fuel valves are de-energized and

the Air Dampers are placed in the light off position in prepara-

tion for the next firing cycle. The opening distance of the Air

Dampers is controlled by positioning the Air Damper Drive Arm

(13) relative to the Acorn Nut (16) mounted on the end of the

Hydraulic Cylinder piston rod. The maximum travel is with the

Damper Drive Arm positioned to be in contact with the hydraulic

oil cylinder Acorn Nut at all times. If less travel is desired, set the

Air Damper Drive Arm to allow a gap between it and the Acorn

Nut. (Depending on Air Damper positioning, it may be

necessary to loosen its set screws to attain proper Air Damper

opening distance.) The wider the gap (when the burner is off),

the less the overall travel when going to the high fire position.

When setting the Drive Arm position relative to the Acorn Nut,

make certain that the Air Dampers’ travel is correct for proper

combustion at all firing positions and that there is no binding

of the Linkage or Dampers. Make certain the cast iron Linkage

Return Weight (5) is secure on its Air Damper Arm (17).

* Not shown in this depiction. See page 4, Figure 2

Note 1

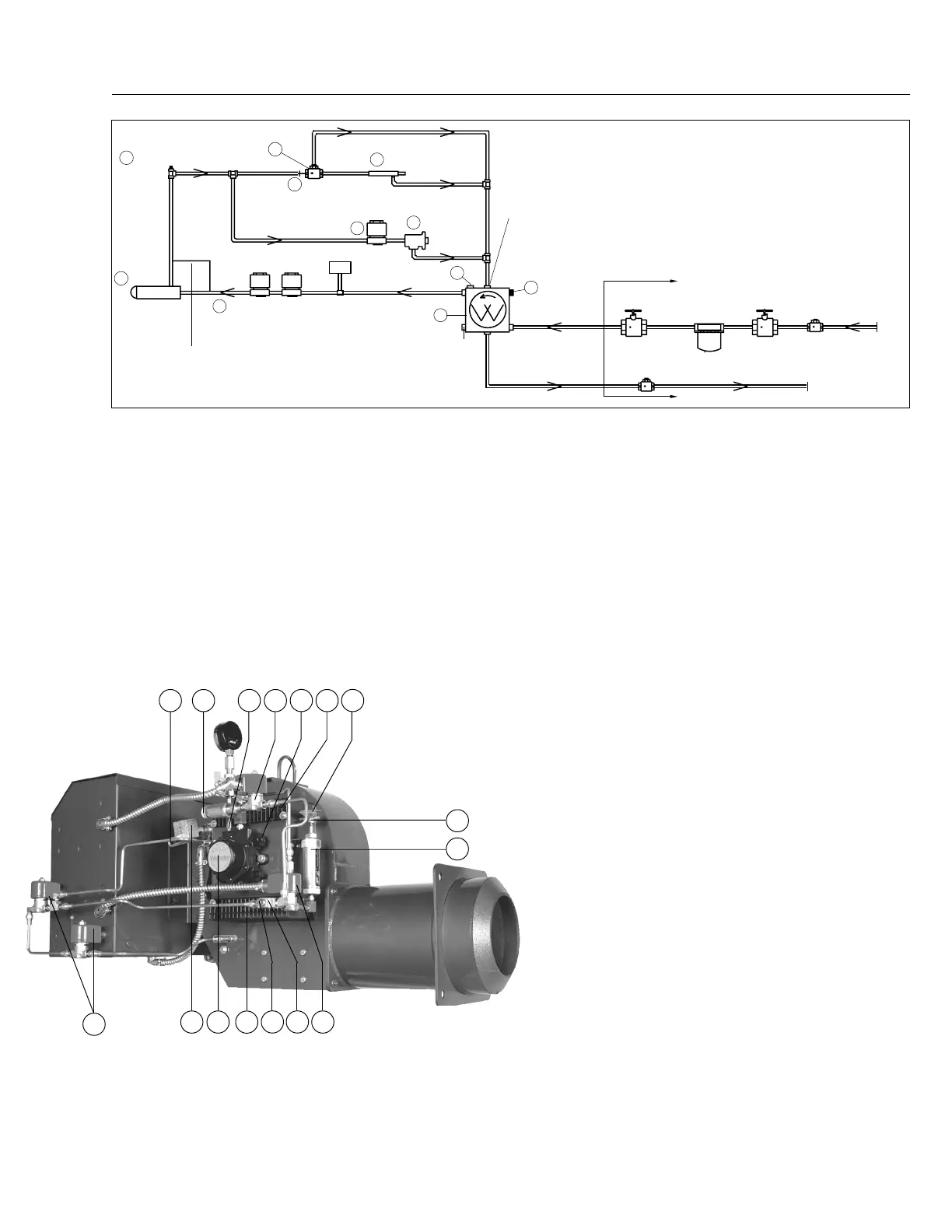

The system depicted in Figure 23 uses a Webster Model 22R oil

pump. If your system uses a Suntec H model pump, the sequence

14

Nozzle

1

Oil Solenoid

Valves

Field Piped

Low Oil

Pressure

Switch **

Oil Pump

2

Nozzle Port

Return Port

Inlet Port

Check Valve

(At Tank)*

Shutoff

Valve*

Fusible Link Valve

(If Required by Code)*

Filter*

Check

Valve*

Inlet

Return To

Tank

Field Piped

Pressure

Gauge Test Port

6

* By Others Unless Specified

on Order.

** Burners with Remote Pressure

Atomizing Oil Pumps require a

Low Oil Pressure Switch.

CAUTION:

All field piped components must be

mounted in the proper location

and proper direction of oil flow.

CAUTION:

Oil supply pressure to Burner

Pump must not exceed 3 PSI per

NFPA Code.

DO NOT USE TEFLON TAPE

15

Pressure

Tap

3 Way Oil

Valve

10

NO

C

NC

12

#72 Drill

Orifice

7

Return

Oil Valve

Low Fire

Regulating

Valve

9

Damper Cylinder

3

1

/

8

” Allen Screw

Under Cap For Oil

Nozzle Pressure

Adjustment

Vacuum Gauge

Inlet Port

Optional Return Port

For Simplex Nozzle Use Alternate

Connection to Tee on Outside of

Burner Instead of Connection to

Nozzle Adapter

Figure 23

Typical Oil Burner with Low-High-Off or Low-High-Low Fuel/Air Control Mode Using Webster 22R Oil Pump

8

C19

Rev.304

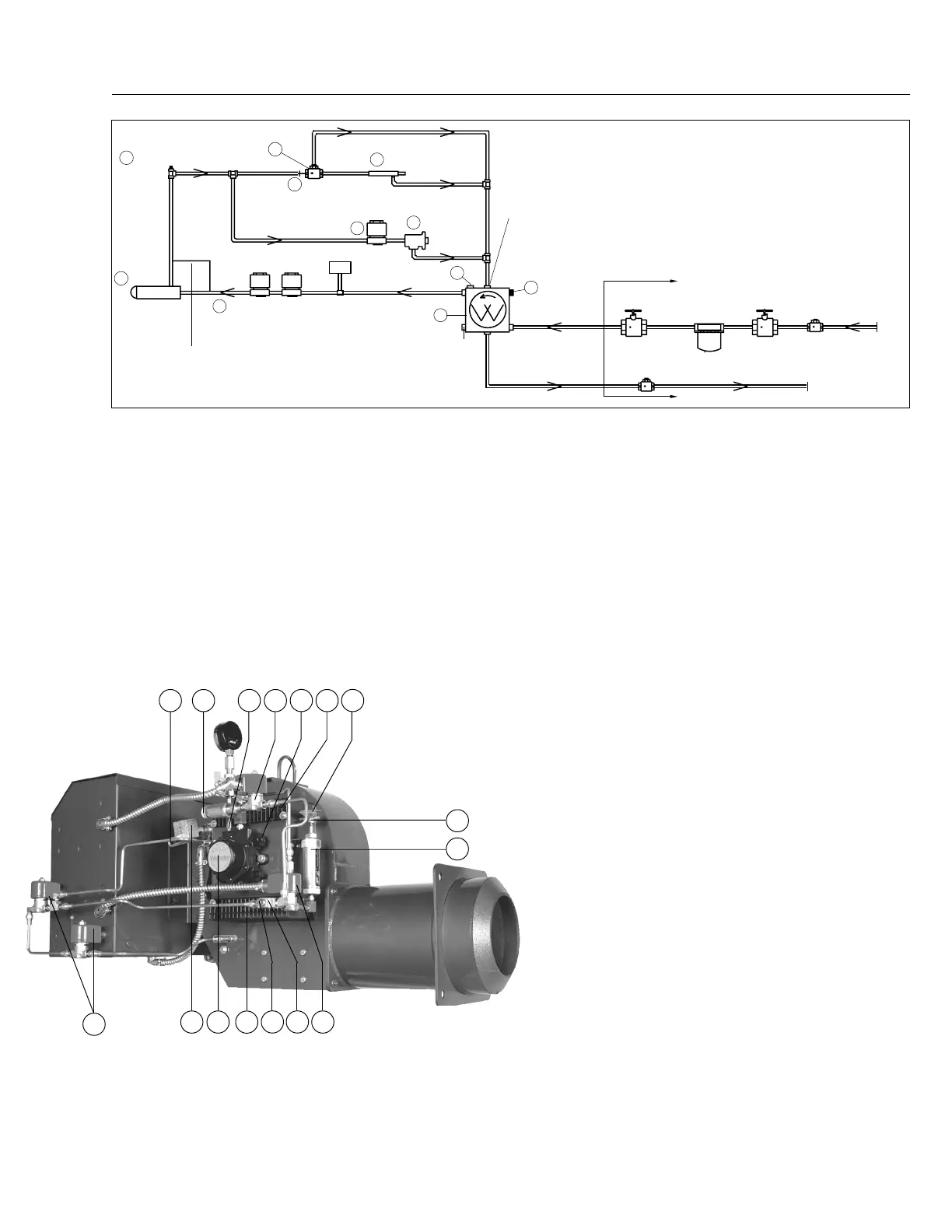

MECHANICAL OPERATION: This Low-High-Off system uses

a two-stage Oil Pump (2) with a Simplex Oil Nozzle (see

note 1, page 20) or an internal bypass nozzle in conjunction

with Movable Air Dampers (4) to provide a low fire start and

a high fire run sequence. A direct spark oil ignition system is

standard on typical oil burners (a gas pilot is standard on

Gas/Oil burners) at firing rates up to 45 GPH, with a spark

ignited gas pilot* to ignite the main oil flame above that

point. Certain insurance company codes could require the

gas pilot system on lower input sizes. Nozzle supply

pressure is set by adjusting the Oil Pump Pressure

Regulator (3). Turn clockwise to increase the pressure and

counter-clockwise to decrease the pressure to the Nozzle.

Nozzle supply pressure is taken at the plugged Pump

Nozzle Pressure Gauge Port (6). Nozzle supply pressure

will normally be approximately 300 PSI at both high and low

firing rates. Flow rate pressure for both high and low fire

is taken at Bypass Pressure Gauge Tee (15). Low fire

pressures are set by adjusting the low fire Regulating Valve

(8). Turning the low fire Regulating Valve adjustment nut

clockwise will increase the pressure at the Bypass Pressure

Test Tee Gauge (increasing the low fire input) and counter

clockwise will reduce the pressure at the gauge (decreasing

the low fire input). Low fire return pressure will normally be

in 60 to 100 PSI range and at high fire in the 180 to 225 PSI

range, but both pressures will vary according to the specific

nozzle being used, as well as job conditions. At light off, the

Main Oil Solenoid Valve (1) is energized, allowing fuel to

3617 8 1347

1

25

9

16

1015 12

4

Loading...

Loading...