For RTD and linear resistance input sensors, cable resistances of up to 50 W per wire can be

compensated if 3- or 4-wire connection is configured.

For thermocouple sensors, cold junction temperature errors can be compensated, either by an

internally mounted temperature sensor, or by an accessory connector with a built-in temperature

sensor. The selection of CJC measurement must be done and verified by the end user.

6 Functional specification of the non-safety functions

The status relay (terminal 33 and 34), error signal on power rail (terminal 91) and LED outputs

are not suitable for use in any Safety Instrumented Function.

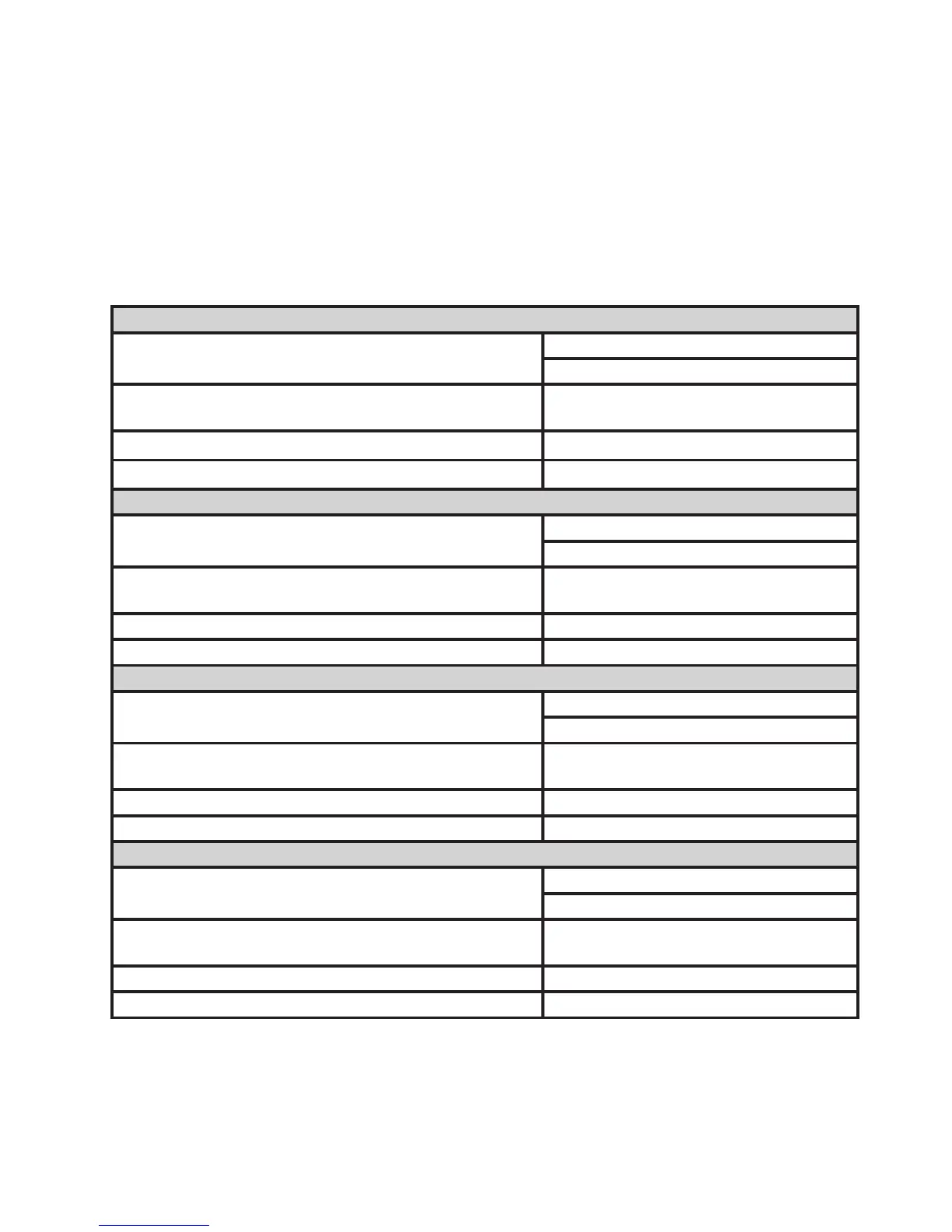

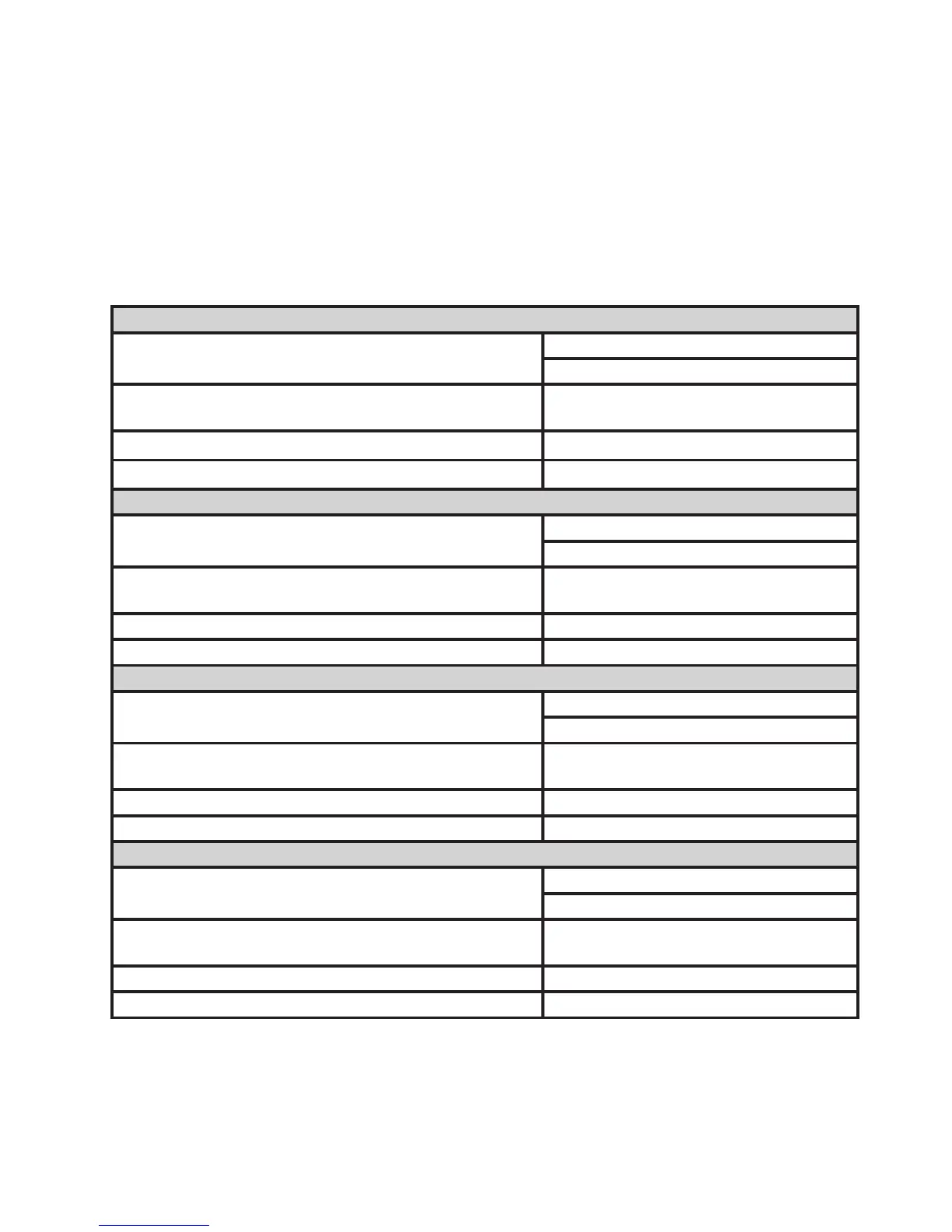

7 Safety parameters

RTD, TC, LinR and Potentiometer input, Current output

Probability of dangerous Failure per Hour (PFH) 4.30E-08

Note

1

Probability of failure on demand (PFD) -

1 year proof test interval

2.82E-04

Proof test interval (10% of loop PFD) 4 years

Safe Failure Fraction 93%

RTD, TC, LinR and Potentiometer input, Relay output

Probability of dangerous Failure per Hour (PFH) 6.20E-08

Note

1

Probability of failure on demand (PFD) -

1 year proof test interval

4.03E-04

Proof test interval (10% of loop PFD) 3 years

Safe Failure Fraction 90%

Voltage input, Current output

Probability of dangerous Failure per Hour (PFH) 5.60E-08

Note

1

Probability of failure on demand (PFD) -

1 year proof test interval

3.66E-04

Proof test interval (10% of loop PFD) 3 years

Safe Failure Fraction 93%

Voltage input, Relay output

Probability of dangerous Failure per Hour (PFH) 7.60E-08

Note

1

Probability of failure on demand (PFD) -

1 year proof test interval

4.89E-04

Proof test interval (10% of loop PFD) 2 years

Safe Failure Fraction 91%

Loading...

Loading...