16

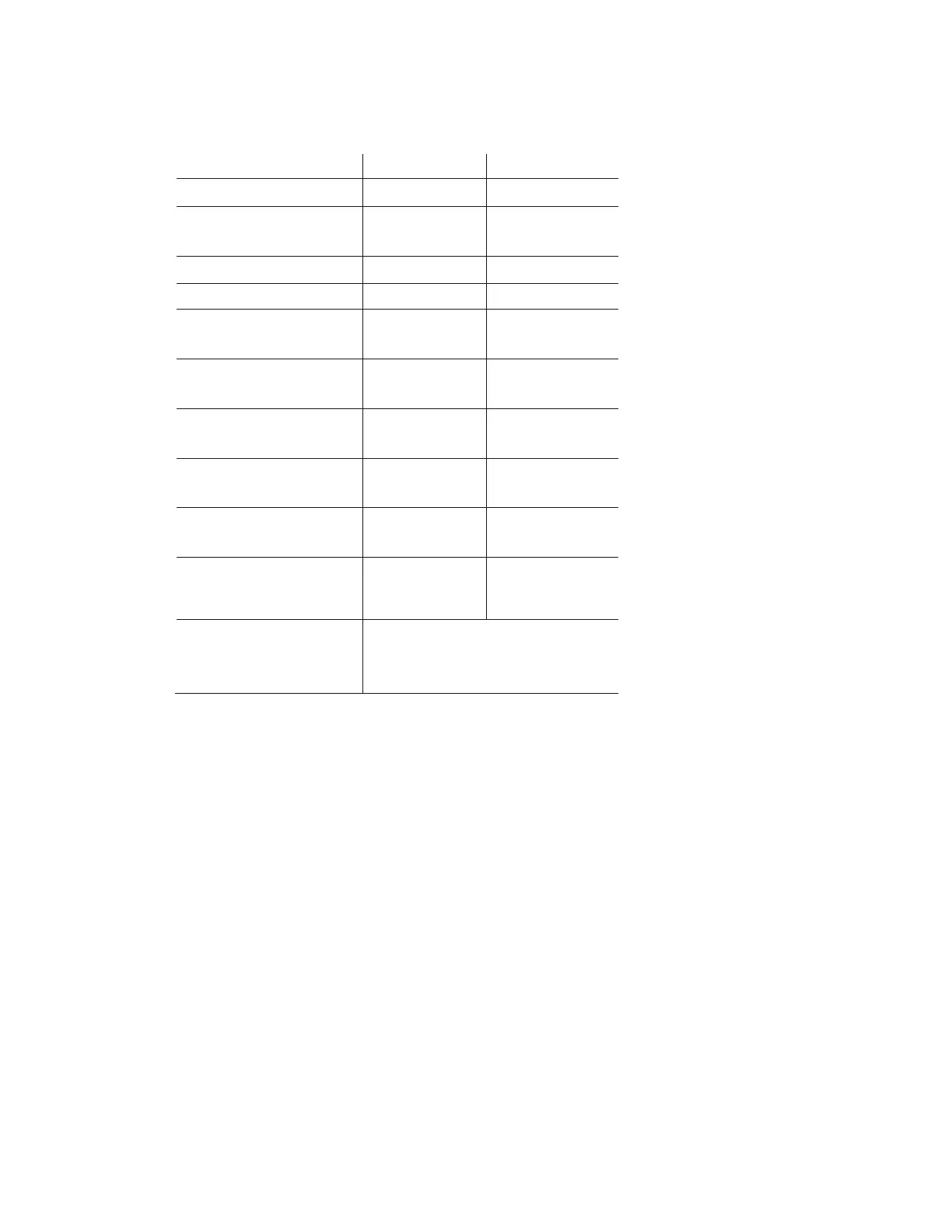

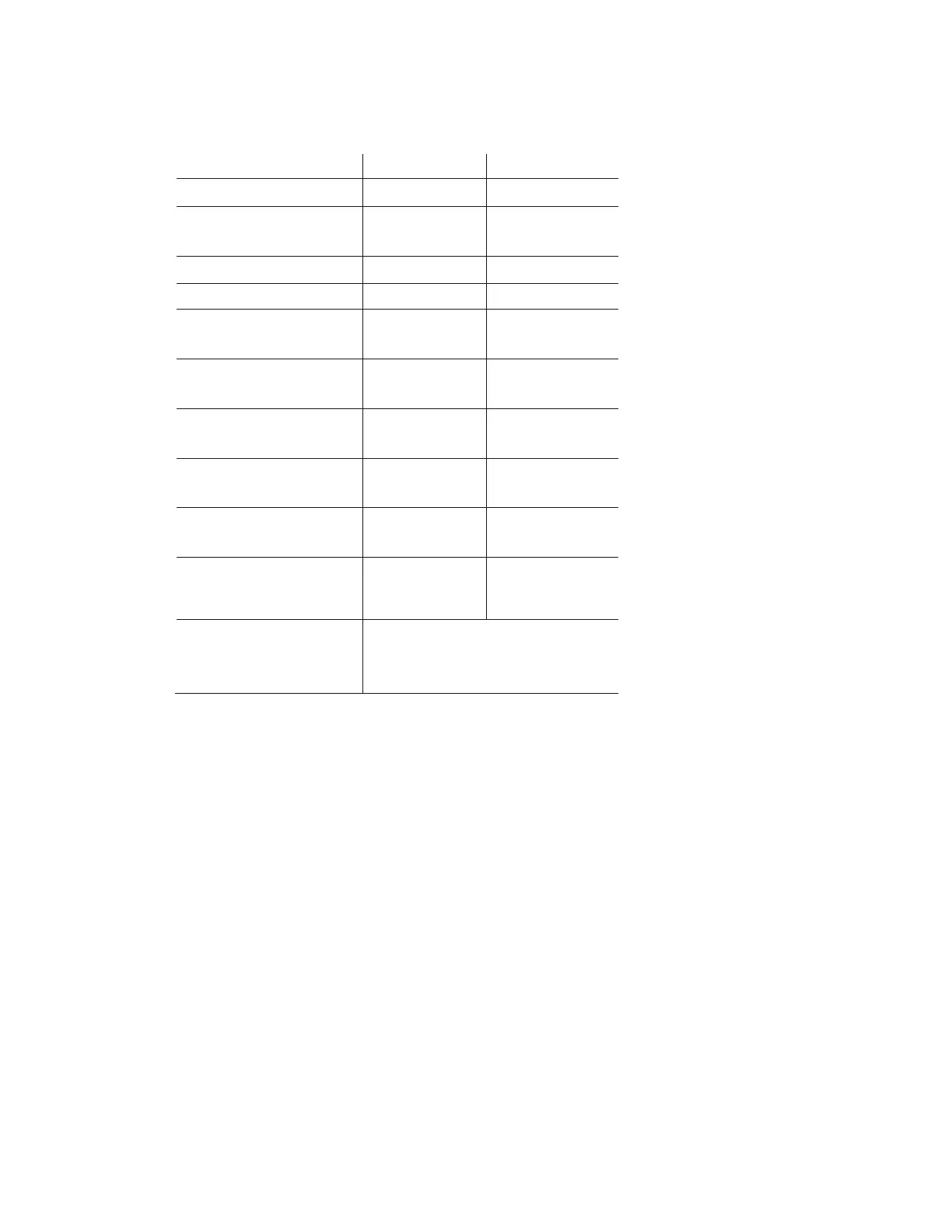

Label Stock

Width of through-hole

opening

Gap Sensor Adjustment

Range (from left edge)

Reflective/Black

Mark Width*

However, this is adjustable via

the left margin offset.

* The Reflective/Black Mark should be opaque to infrared light. The mark should be

between the labels. The end of the mark should correspond with the beginning of the

label.

** This is the recommended maximum. There are two factors that determine whether

the Printer will accept any particular stock thickness.

1. The ability for the Printer to pull the paper through the print area.

2. The ability for the sensor to read through the backing if the sensor is set to die-cut.

If you are printing in continuous or reflective label sensing mode number 2 does not

apply. The fact that the Printer must read through the backing in die-cut mode will

limit the thickness much more than the Printer's ability to pull the paper through the

print area. However, if you adjust opacity level of the liner enough to allow the label to

be seen by the stock sensor, the thickness will only be limited by the Printer's ability to

pull it through the printer area. For these reasons the weight or thickness of the liner

is a variable that cannot easily be defined. Primera recommends and uses 40# liner

with all label stock. It is important to test all label stock with the intended Printer

before ordering large quantities!

Loading...

Loading...