6 Single-Sided Welding

Page 31

All Info Copyright © Pro Spot International Inc.

Figure 6.31

The i4 can also be fitted with a stitch weld adapter enabling the operator to lay

staggered bead type welds. While rolling the tip on the sheet metal edge, the

welder will automatically deliver an intermittent or pulsating current.

1. Push the Single-Sided weld mode button (fig 6.3). Single Sided Weld Programs

will display on the screen (fig. 6.5). The i4 software defaults to Single Spot Weld

Mode (fig. 6.6).

2. Select Stitch Welding Program by pressing the Left or Right Navigatioin

Buttons (fig. 4.9). Make sure that Stitch Welding graphic appears on the screen

(fig. 6.31)

3. Choose weld power level by pressing the “Next Program” button repeatedly.

(refer to section 4.6 "Setting the weld program").

4. Fit Single-Sided gun with the stitch electrode (fig. 6.33).

5. Prepare the surface area by removing paint and primer.

6. Ground the working area (refer to section 6.1 "Single-Sided Welding

Overview").

7. Roll the tip on the sheet metal edge while keeping the trigger depressed. The

welder will automatically deliver an intermittent or pulsating current.

8. Repeat as needed.

This procedure works well on stainless steel, and therefore lends itself well

to rust

repair and patching. It's easy to use and can be manipulated to fit any shape or

form you require.

Figure 6.33

Tip: You can use stitch electrode to weld pulling tabs onto areas that

need to be pulled.

6.10 Stitch Welding

i4

Astuce: vous pouvez utiliser l'électrode de point à souder tirant

des onglets sur des endroits qui ont

besoin d'être tirés.

6 Single-Sided Welding

Page 32

All Info Copyright © Pro Spot International Inc.

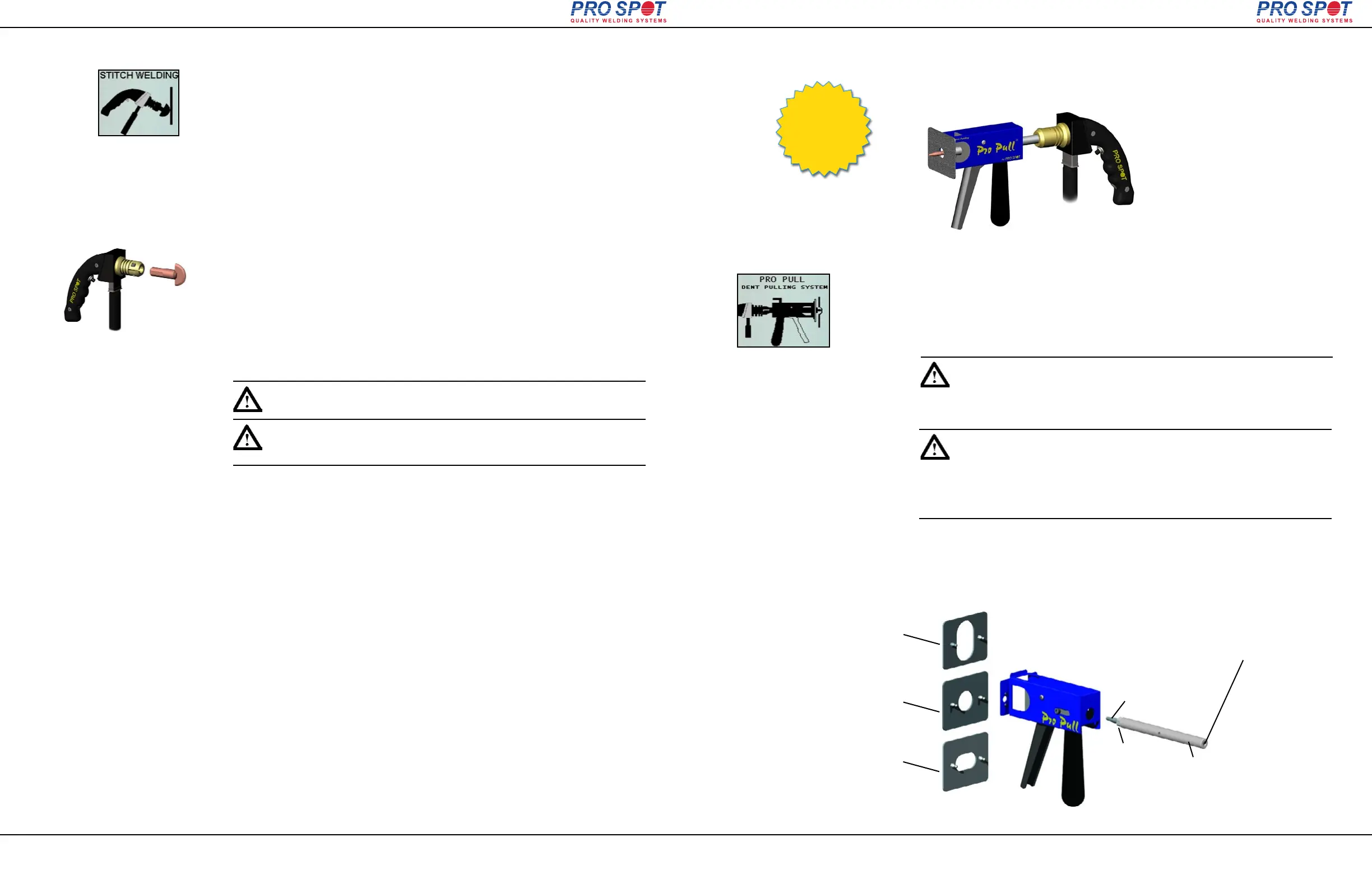

Pro Pull comes with three different

Blocking Plates with Quick-Connect design.

Block window size:

2.5"(63mm) x 1.5"(38mm)

Block window size:

1.75"(44mm) x 1"(25mm)

Block window size:

0.75" (19mm) dia.

PP-10-04

PP-10-03

PP-10-01

Large openings for

great visual control

of the pulling area.

Retrofit point for different end adapters.

Available for most weld guns.

(not included) See prospot.com for more

information.

Removable weld shaft.

The weld current is

transferred through the shaft

and NO CABLE is required

to transfer the current

CLT-55

Electrode

N-38

Nut

CLP-75

1. Push the Single-Sided weld mode button (fig 6.3). Single Sided Weld Programs

will display on the screen (fig. 6.5). The i4 software defaults to Single Spot Weld

Mode (fig. 6.6).

2. Select Pro Pull Welding Program by pressing the Left or Right Navigation

Buttons (fig. 4.9). Make sure that Pro Pull Welding graphic appears on the screen

(fig. 6.6).

Figure 6.6 Selecting Pro Pull

weld mode

Make sure the ground plate is clamped firmly in place on the inside of a

clean metal surface as near as possible to the weld location.

NOTE: Do not attach the ground to the metal you're about to weld on.

When performing other weld tasks such as dent pulling, etc., the ground

attachment location becomes less critical.

Pro Pull can be

fitted to most

resistance spot welders

or dent pullers.

Welder & Adapters

not included.

Pro Pull is a patented, innovative tool for fast and accurate dent pulling. It

features paintless dent removal functionality (see sec. 6.3.5 “Paintless Dent

Pulling With Pro Pull”).

6.11.2 Pro Pull Component Diagram

6.11.1 Selecting Pro Pull Weld Mode

6.11 Pro Pull Dent Pulling (optional)

i4

Assurez-vous que la plaque de terre est serré fermement en place à

l'intérieur d'une surface propre de métal le plus près que possible au lieu

de soudure.

NOTE: Ne fixez pas le terre et le métal que vous êtes sur le point de

soudre. Lors de l'exécution d'autres tâches comme la soudure dent de

traction, etc, le terre du lieu de saisie devient moins critique.

Loading...

Loading...