All Info Copyright © Pro Spot International Inc.

4 Operation

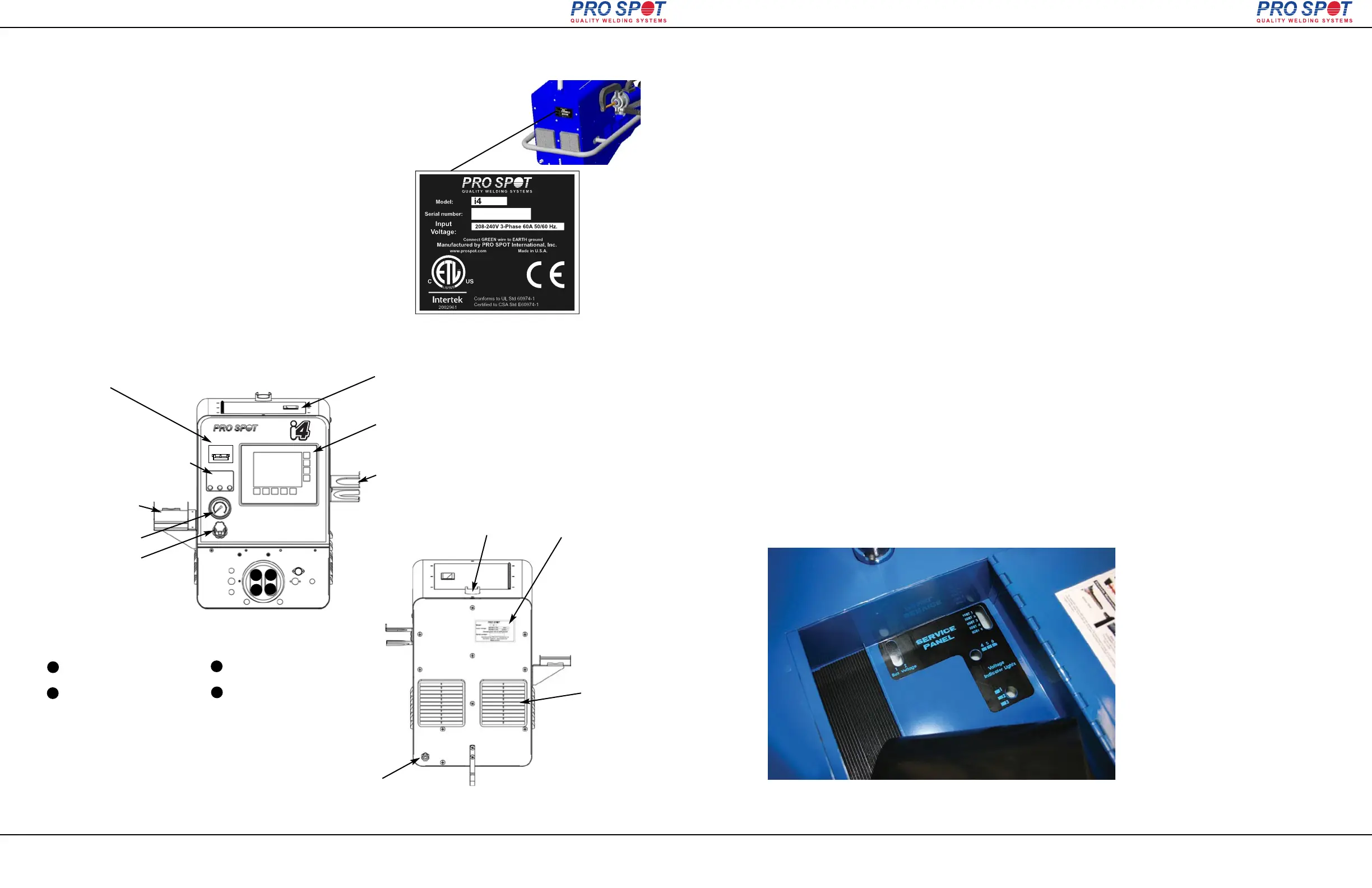

The welder is supplied with one of the following voltage and frequency combinations:

Input voltage: 3 phase

208-240V 50/60 Hz. OR

400-420-480V 50/60 Hz.

The actual voltage and frequency is stated on the rear panel name plate.

Open circuit output voltage 20v max. E.M.C. classification is C1SPR 11.

Welding amperage: 12500A max (3-phase)

Cable length: 8’ (2.5m) standard

Electrode Pressure: At 7 bars (90 PSI)-280 DaN (616 Lb)

At 9.5 bars (135 PSI)- 420 DaN (924 Lb)

Cooling system: Air (2 fans), Compressed air

(weld gun and weld cables)

Water Cooling

(inverter, transformer, welding gun)

Micro processor: i4 Upgradeable Software Platform

Shipping Weight (standard): 373lb (169kg)

Air Pressure Regulator

Display Screen

Power Switch

Input Voltage Phase Indicator LED

Lights should illuminate when

Power switch on front panel is "ON"

(2 lights for 1 phase or 3 lights for 3

phase)

Cable Holder Bracket

Name Plate shows:

Input voltage,

Serial number, etc.

Cooling Fan

Air Input

Connect filtered air

100 PSI 7 BAR (min)

1

2

3

Single-Sided ground cable

Two-Sided spot gun cable

Single-Sided Weld Gun cable

Two-Sided ground cable

WELD CABLES CONFIGURATION

4

The name plate is at the rear of the welder unit.

The required voltage is indicated on the label.

Welding output is rated at 15V.

Figure 4.1 i4-Front View

Figure 4.2 i4-Back View

Page 11

4.2.2 Getting familiar with your welder

4.2.1 Welder Overview & Technical Specifications

4.2 About your welder

Air Pressure Gauge

1

2

4

3

Two Sided Gun Holder

Single Sided Gun Holder

Tool Storage Tray

Cable Holder

i4

90021

All Info Copyright © Pro Spot International Inc.

4 Operation

Page 12

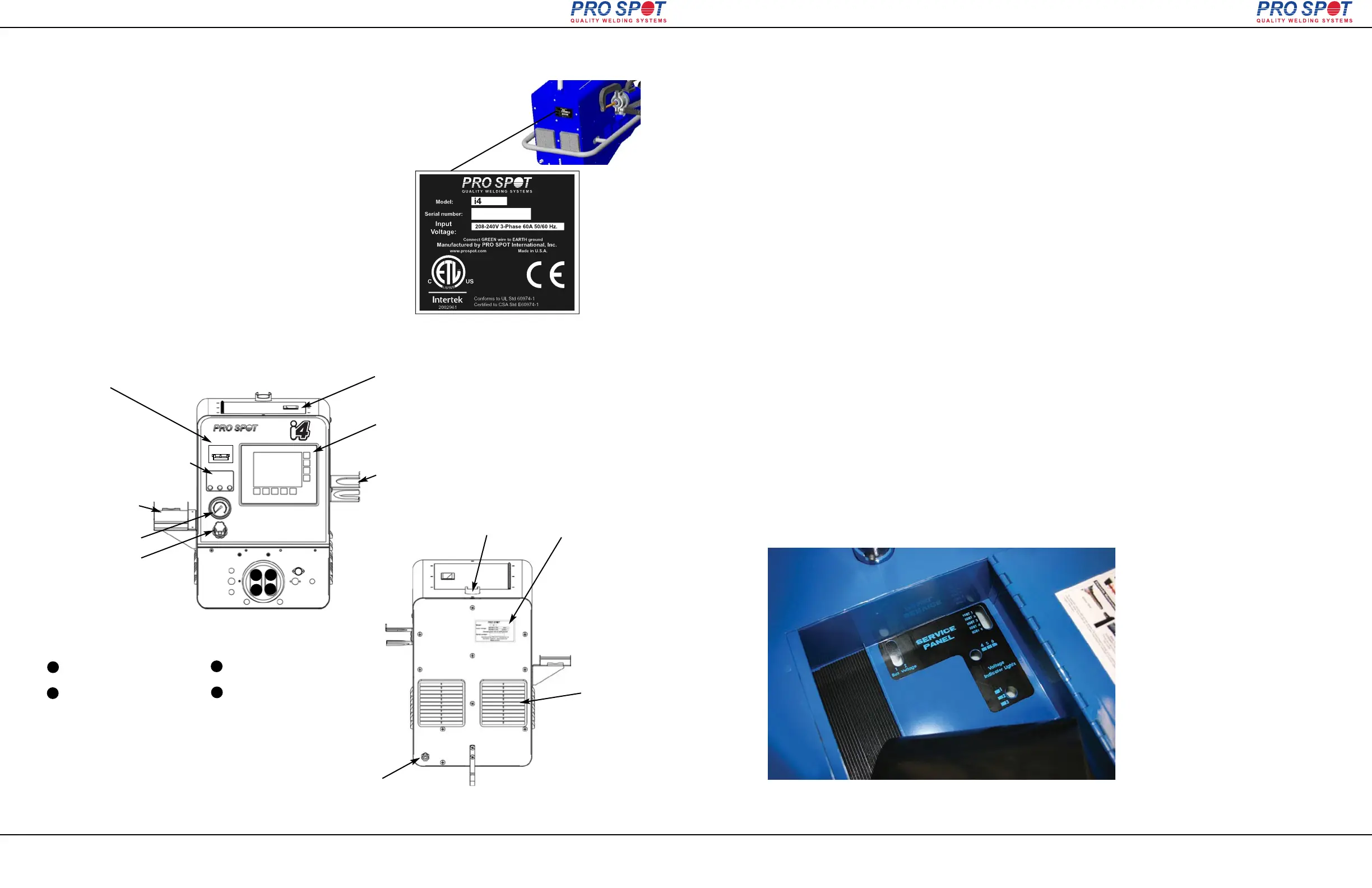

4.2.5 Service Panel Window – Control System Status Lamps

i4

Location: Inside the i4 and PR-2000 tool & accessory tray (under the rubber mat).

Purpose: To quickly determine the status of many internal systems without opening the

welder. The welder needs to be powered up. Look down through the window. There

are several lights to watch for. The Voltage Indicator windows have three LED lights in

each window, while the IGBT and Bus Bar windows have only one light per window.

NOTE: D means diode while the number determines the device’s board location.

1) Buss High Voltage OK: LED1 & 2 indicate 300 volts DC present. Both stay ON (but

often only one of them is seen unless top cover is removed).

D06= present

D26= present.

2) IGBT Control System OK: LEDs 1, 2, 3, 4 indicate voltage present across each

IGBT gate. Each LED should stay ON. LED 5 (yellow) indicates 15VDC control voltage

and should stay ON. These diodes are on a separate, vertically-mounted mini-board.

D107 = present

D108 = present

D109 = present

D110 = present

D101= 15V present

3) AC Input - Voltage Drop Condition: LEDs 4, 5, 6 indicate a problem if any of them

comes ON during welding. They all come on briefly during startup then stay OFF.

D23= Primary voltage drop 10%,

D22= Primary voltage drop 15%

D21= Primary voltage drop 20%

4) DC Voltage Indicators, LED 1, 2, 3 indicate logic voltages generated and present.

They come ON during startup and stay ON.

D10= 15V present

D11= 18V present

D12 = 24V present

Service Panel Window –

Control System Status Lamps

Tool tray mat removal required to view Service Panel Window.

Loading...

Loading...