2 Safety

Page 7

All Info Copyright © Pro Spot International Inc.

When the Spot Gun is used continuously, the welding cables and the power trans-

former get hot. To prevent the welder from malfunctioning due to overheating, it is

cooled using the built-in air, and liquid cooling systems. The air cooling system

cools the welding cables and the water cooling system coold the transformer,

inverters, cable ends and the spot gun.

i4 features an air cooling system that cools all four welding cables.There are two

different Cooling Modes: "AUTO" (default) and "MANUAL". In the "AUTO" mode,

the air cooling system turns on automatically after 15-30 welds and forced air

starts to flow through the cable. In the "MANUAL" mode the cooling system oper-

ates continuously.

To switch to “MANUAL” mode:

1) Restart the software and press “HELP” button while start-up screen is dis-

played. “System Settings” screen will display (fig. 2.1).

2) Select “System Settings” by pressing the Navigation button, Up (fig. 2.2).

3) Select “Manual Cooling” by pressing the Navigation button, Down (fig. 2.3).

AIR COOLING will activate.

The Liquid Cooling system is turned ON and OFF with the switch on the Front

Panel (fig. 2.3a). The water tank is located in the rear of the unit, inside the

center column. The watertank should be filled with a 50/50 water & antifreeze

solution (fig. 2.3b).

The built-in overheat protection is designed to prevent damage to the welder

caused by overheating. The system will automatically shut off the welder when a

pre-programmed temperature is reached (fig.2.4). DO NOT turn off the welder! It

needs the cooling air to cool the machine faster. Wait until the display returns to

normal (usually 4-8 min.) Shorter duty cycles (due to short weld times and “rest”

periods between welds) will allow the cooling system to function better and may

prevent the auto-shut-off. (Consistently check weld strength by performing

destructuive tests).

IMPORTANT! Do not turn off the welder while the cooling system is

activated!

IMPORTANT! If the thermal breaker has switched off the welder,

please contact Pro Spot's authorized service personnel

Figure 2.1

Figure 2.4

2.3.2 Overheat protection

2.3.1 Cooling

2.3 Safety devices

IMPORTANT! Leave the water cooling ON for faster cool down

Figure 2.2

Figure 2.3

Figure 2.3a Figure 2.3b

i4

For continuous use do not exceed 3 welds per minute. For operation not exceeding

60 minutes: 6 welds per minute. Welding current 9270A for continuous use

12,500A maximum at 1 weld per minute for 5 minutes max.

IMPORTANT! N'éteignez pas le soudeur pendant que

le système de refroidissement est activé!

IMPORTANT! Si le disjoncteur thermique a éteint le soudeur, s'il vous

plaît contactez personnel de service autorisé Pro Spot.

IMPORTANT! Laissez couler l'eau de refroidissement à l'intention

de se refroidir plus rapidement.

3 Installation

The i4 Spot welder is inspected and tested prior to leaving the factory to

guarantee consistent quality and the highest possible reliability. Follow the instal-

lation tips and operating instructions below to ensure user safety and proper

welder performance.

WARNING! Do not operate or place the welder near water, in wet

locations or outdoors. Risk for injuries or damage to the welder.

WARNING! Do not place the welder on unstable or uneven

ground. The welder might fall causing personal injuries and damage to

the welder. Do not operate on a slope of more than 10º.

A grounded electrical plug must be installed (refer to section 3.4 “Connection of

electrical supply”).

Check the contents of the shipping container against the packing list, consign-

ment note, or other delivery documentation to verify that everything is included

and in the correct quantity. Check the i4 Spot Welder carefully to make sure that

no damage has occurred during transport. If anything is damaged or missing, the

welder may be unsafe to use till the part is repaired or replaced. If anything is

missing, please contact your supplier. Remove all packaging material from the

welder.

For your convenience, i4 welder ships fully assembled.

Due to differences in wiring codes and connection methods, no electrical plug

comes with the welder. Consult a certified electrician for proper installation of the

electrical plug.

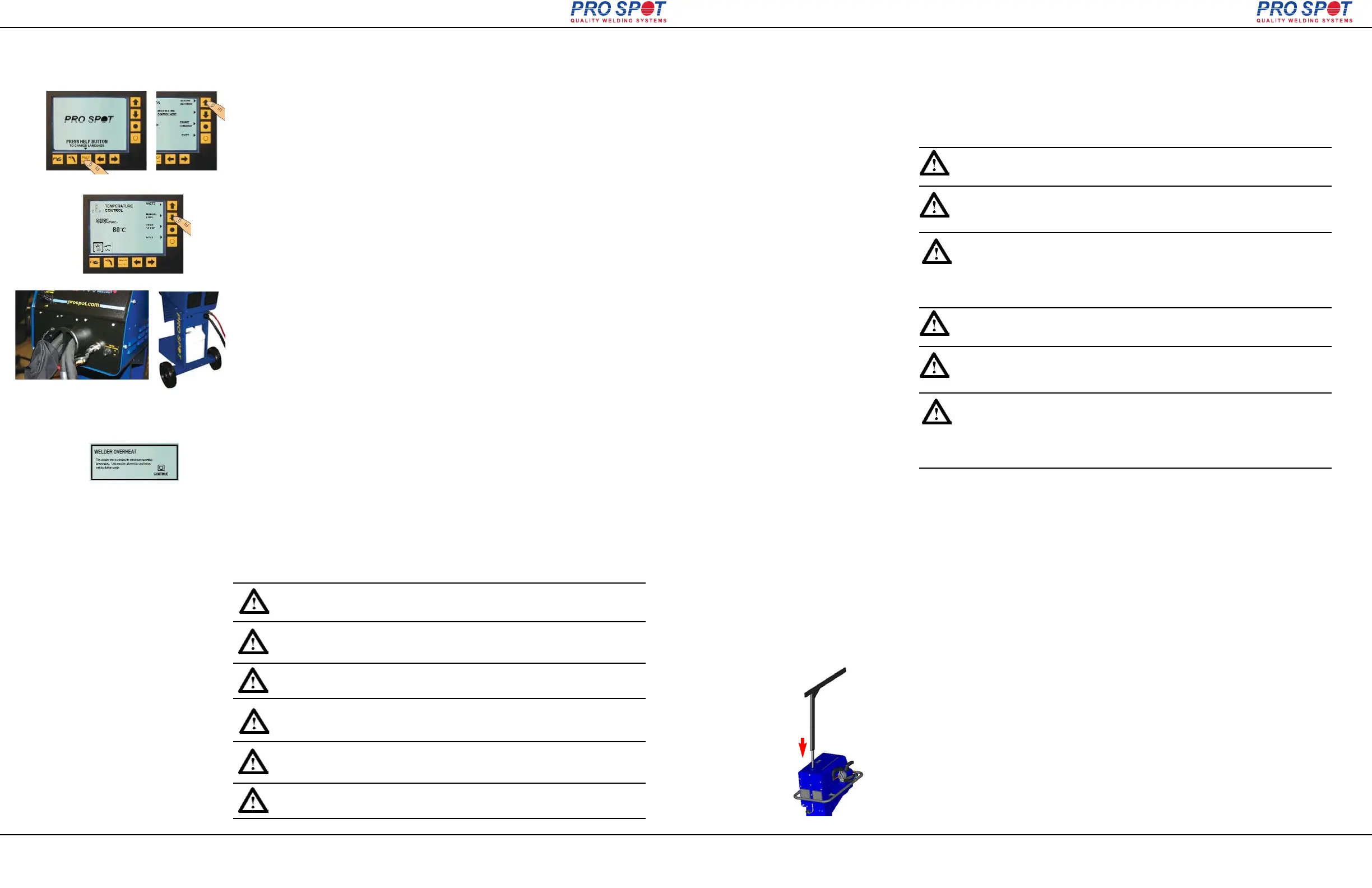

Insert the support arm (boom) as shown in Figure 3.1

Figure 3.1

IMPORTANT! It is the responsibility of the owner to ensure that

the equipment has been installed as specified in the instructions pro-

vided. It is also the owner's responsibility to ensure that the welder

is inspected in accordance with applicable regulations before it is

put into service. Do not use for thawing out frozen water pipes (17.1)

ATTENTION! Ne pas faire fonctionner le soudeur près de l'eau, en voie

humide ou à l'extérieur. Risque de blessures ou de dommages au soudeur.

ATTENTION! Ne placez pas le soudeur sur un sol instable ou irrégulière.

Le soudeur peut tomber causant des dommages graves au soudeur.

Ne pas utiliser sur une pente de plus de 10º

IMPORTANT! C'est la responsabilité du propriétaire de s'assurer que

l'équipement a été installé comme spécifié dans les instructions fournies.

C'est aussi la responsabilité du propriétaire de s’assurer que le soudeur est

inspecté conforment à la réglementation applicable avant qu'il ne soit mise

en service. Ne pas utiliser pour dégeler les conduites d'eau congelées (17.1)

Page 8

All Info Copyright © Pro Spot International Inc.

3.3 Welder assembly

3.2 Packaging and delivery inspection

3.1 General

3 Installation

i4

Loading...

Loading...