All Info Copyright © Pro Spot International Inc.

4 Operation

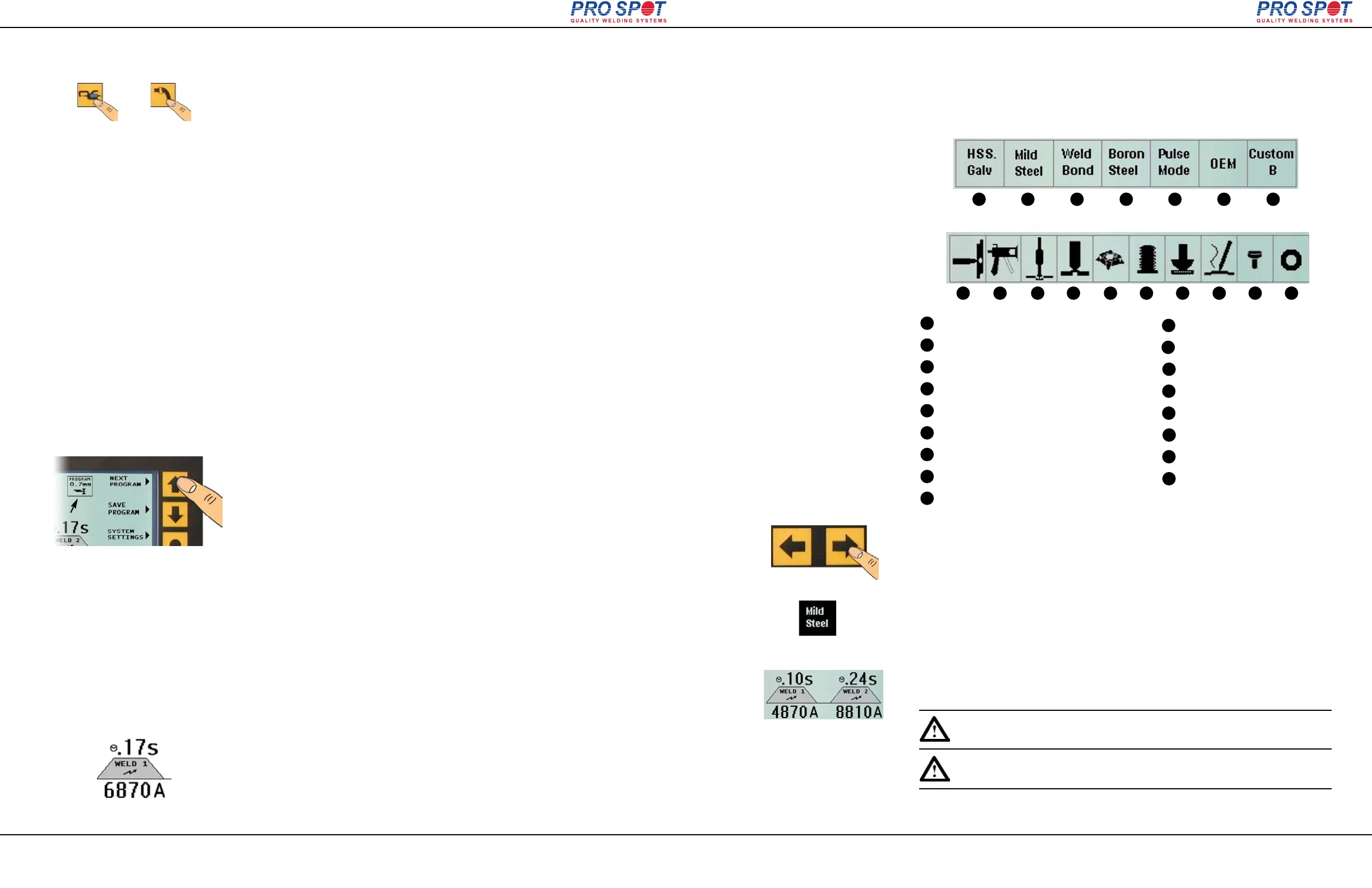

The i4 features 6 different strength weld power modes. It defaults to 0.7mm pro-

gram. To change weld program press “Next Program” (fig. 4.7).

The program box indicates the weld power (thickness).

For example, when welding two HSS Galv. metals that are 1.2mm thick, you

should use the 1.2mm program.

If more power is desired, press “Next Program” to reach the next level.

NOTE: The Factory Password (1234) must be entered in order to modify weld

programs. To enter the Factory Password press the Help button while booting at

the third screen to access the System Settings menu. The text located near the

Down Arrow button reads WELD SETTING CONTROL MODE: AUTO/MANUAL.

Auto is selected by default. Press the Down Arrow button to enter Manual mode.

In the PASSWORD REQUIRED pop up window enter 1234 using the arrow keys.

Exit by pressing the Open Circle button. The welder is in manual mode and weld

programs can now be modified.

The time and current automatically change with each respective weld power

mode.

Referring to fig. 4.8: The top value indicates the time duration that will be applied

during the weld and the bottom value indicates the weld power in weld amperage

that will be applied during the weld.

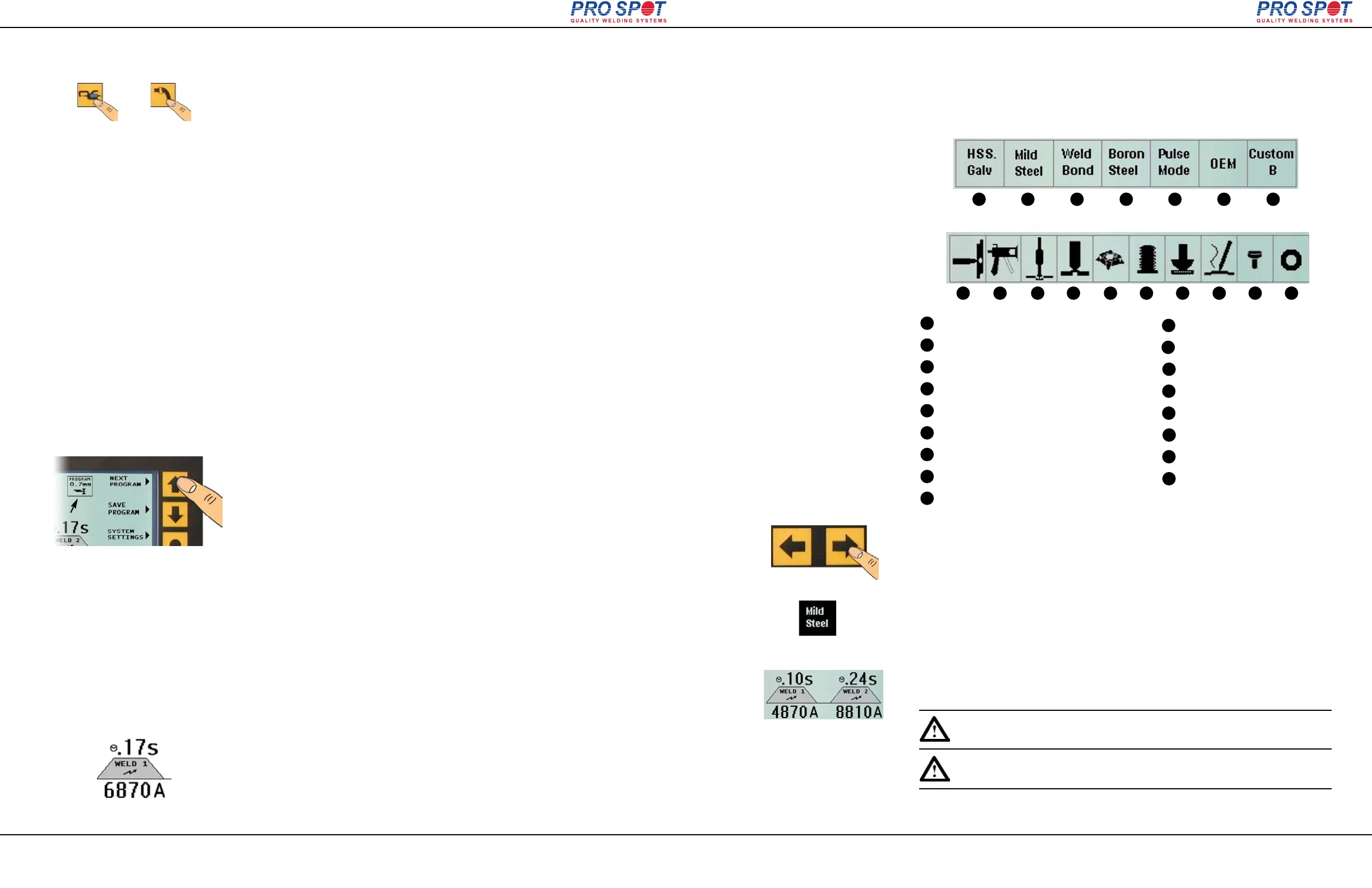

The i4 is a multi-functional resistance spot welder. It is equipped with a four weld

cable system for your convenience. Two of the weld cables are connected to the

Two-Sided Spot Gun and the other two are connected to the Single-Sided Weld

Gun.

To select a weld mode, press the respective mode button (fig. 4.6)

Once the welding mode is selected, a group of related weld programs become

available to the user (see section 4.8 “Setting the default weld programs”)

Figure 4.6

Pneumatic air is used for:

- forcing the spot gun to close and open.

- cooling the welding cables that are connected to the spot gun.

The air pressure is regulated with the air regulator, and the set pressure is indicat-

ed on the pressure gauge. Default pressure is 90 PSI.

Change the air pressure as follows:

1. Unlock the pressure regulator by pulling on the adjustor knob till it snaps into

the unlocked position.

2. Turn the pressure regulator knob clockwise to increase or counter-clockwise to

decrease the air pressure.

3. Lock the pressure regulator by returning the knob to the lock position.

Figure 4.7

Figure 4.8

Page 15

4.7 Setting the weld time and current

4.6 Setting/Changing the weld program

4.5 Setting the pneumatic air pressure

4.4 Choosing the weld mode

i4

4 Operation

4.8 Setting the default weld programs

There are 17 weld programs featured in the i4 Spot Welder. Ten of these pro-

grams are associated with the Single-Sided Gun and seven are associated with

the Two-Sided Spot Gun.

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

HSS Steel / Galv. Steel Welding

Mild Steel Welding

Weld Bonding

Boron Steel Welding

Pulse Mode

OEM-Specific Programs

Custom Program

Single-Sided Spot Welding

Pro Pull Dent Removal

Note: Two-Sided welding mode and Program No. 1 are set by default

when the i4 is turned on.

Page 16

All Info Copyright © Pro Spot International Inc.

12

13 14

15 16

17

12

13

14

15

16

17

Two-Sided Programs

Single-Sided Programs

Figure 4.9

Dent Pulling

Contact Shrinking

Nut Welding

Bolt Welding

Stitch Welding

Carbon Rod Shrinking

Rivet Welding

Washer Welding

The welding programs are selected on the Control Panel. Select the welding pro-

gram by using the Left and Right navigaton buttons (fig. 4.9)

The selected program is indicated by a highlighted black box over the program

name (fig. 4.10).

In any welding mode there are 6 power level programs: 0.7mm - 2.5mm. To

switch between programs press the “Next Program” button (fig. 4.7).

Some programs require a double-weld in one cycle (fig. 4.11). Those welds auto-

matically deliver Weld 1, programmed delay, then Weld 2. This is a very sophisti-

cated weld feature for controlling exact temperature into the weld area and to pre-

heat it.

Figure 4.10

Figure 4.11

i4

Note: Mode recto- verso de soudage et le programme de soudage n °

1 sont définies par défaut lorsque le i4 est allumé.

Loading...

Loading...