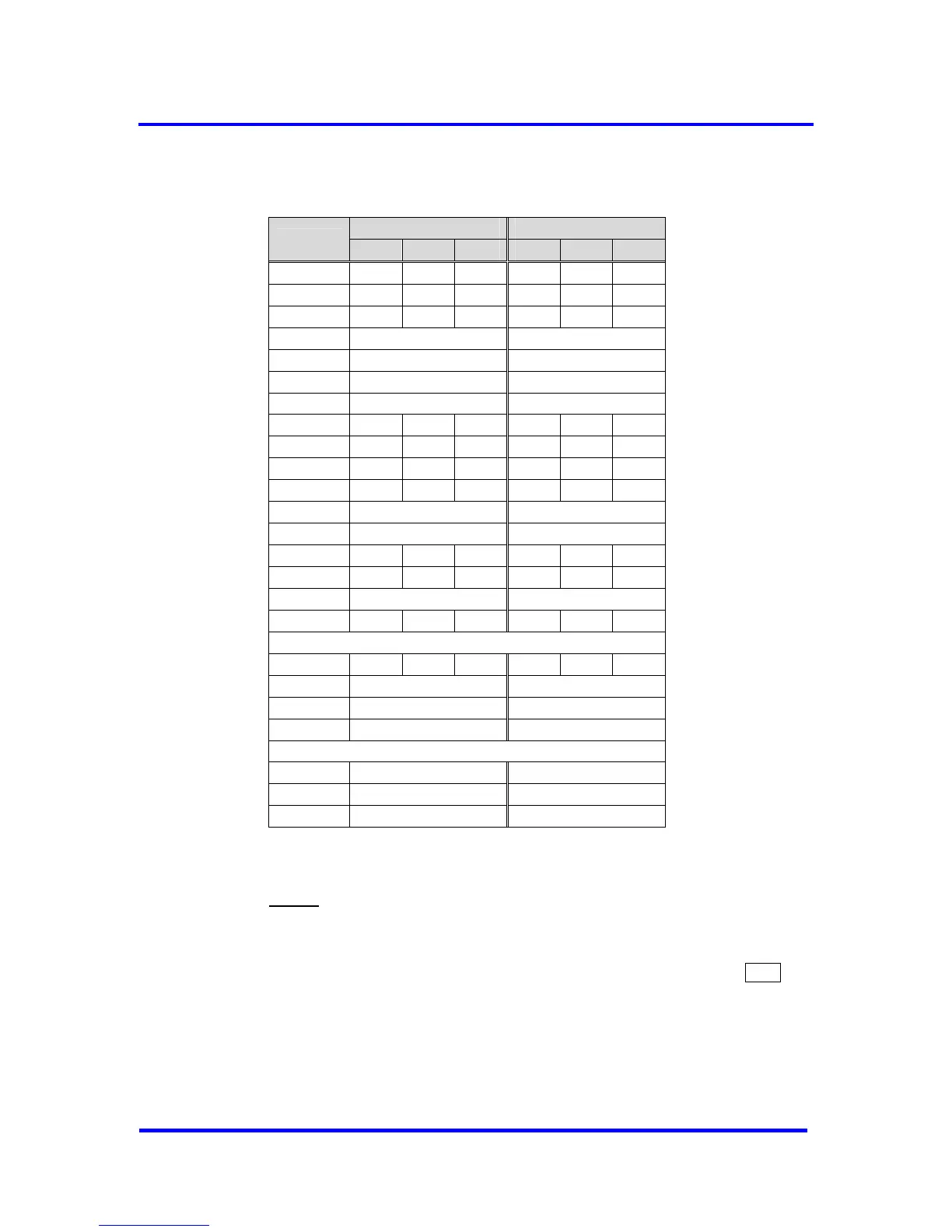

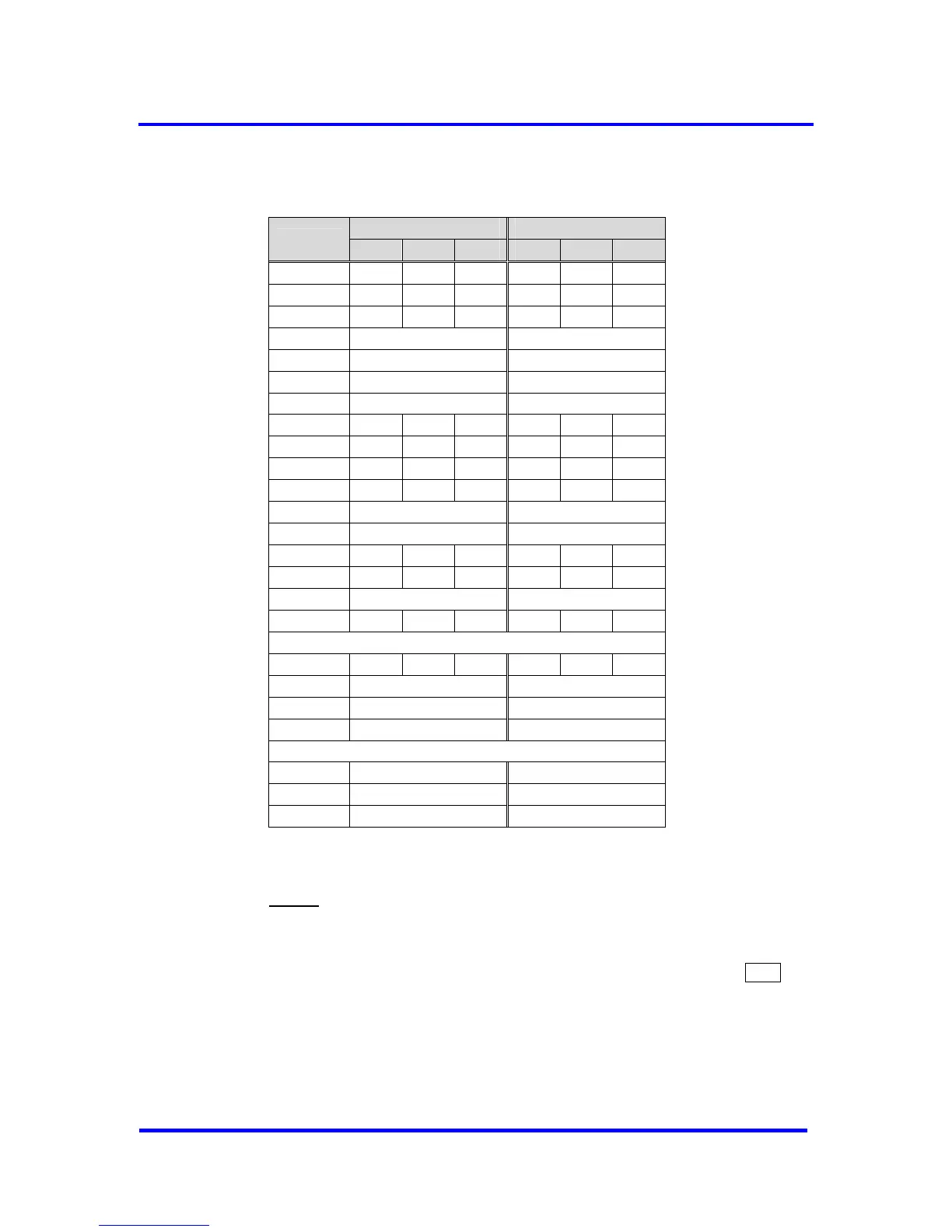

Operational Specifications 10

MILLIMETER INCH

SYMBOL

MIN NOM MAX MIN NOM MAX

A ─── ─── 2.45 ─── ─── 0.096

A1 0.15 0.25 0.35 0.006 0.010 0.014

A2 1.95 2.05 2.10 0.077 0.081 0.083

D 13.90 BASIC 0.547 BASIC

D1 10.00 BASIC 0.394 BASIC

E 13.90 BASIC 0.547 BASIC

E1 10.00 BASIC 0.394 BASIC

R2 0.13 ─── 0.30 0.005 ─── 0.012

R1 0.13 ─── ─── 0.005 ─── ───

Θ 0° 3.5° 7° 0° 3.5° 7°

Θ1 0° ─── ─── 0° ─── ───

Θ2 10° REF 10° REF

Θ3 7° REF 7° REF

c 0.11 0.15 0.23 0.004 0.006 0.009

L 0.73 0.88 1.03 0.029 0.035 0.041

L1 1.95 REF 0.077 REF

S 0.40 ─── ─── 0.016 ─── ───

b 0.22 0.30 0.38 0.009 0.012 0.015

e 0.80 BSC. 0.031 BSC.

D2 8.0 0.315

E2 8.0 0.315

Tolerances of Form and Position

aaa 0.25 0.010

bbb 0.20 0.008

ccc 0.20 0.008

Figure 10-22 : Package Dimensions and Tolerances

Notes:

1. Dimensions D1 and E1 do not include mold protrusion. Allowable

protrusion is 0.25 mm per side. Dimensions D1 and E1 do not

include mold mismatch and are determined at datum plane ─H─.

2. Dimension b does not include dambar protrusion. Allowable dambar

protrusion shall be 0.08 mm total in excess of the b dimension at

maximum material condition. Dambar cannot be located on the

lower radius of the lead foot.

VPC3+C User Manual

Revision 1.03 95

Copyright © profichip GmbH 2004-2006

Loading...

Loading...