VIBTOOL 02.2009

27

Ideal measurement position

When taking vibration measurements using VIBTOOL, care

must be taken to position it correctly. If VIBTOOL is not

held correctly against the machine, unreliable measure-

ment values and damage can occur. So be sure to observe

the following:

• The measurement surface must be metallic, flat and

clean (or, preferably, prepared with the VIB 8.610 coun-

tersink, see page 56 for details). Otherwise, the frequen-

cy range may be reduced due to poor mounting tech-

nique.

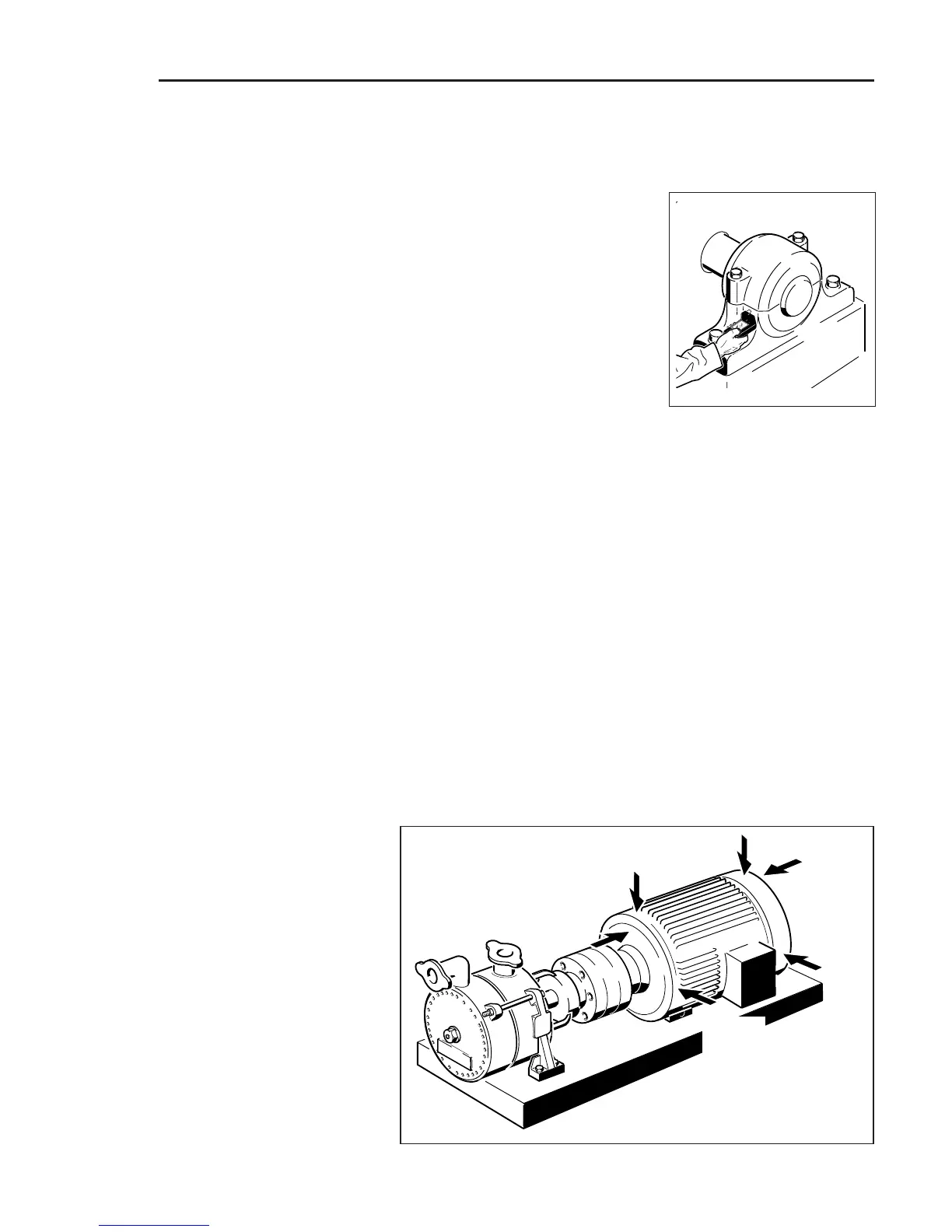

Where to measure

Several measurements should be taken to obtain complete

information for vibration analysis: four radial readings

(offset from each other by 90°) and one axial reading.

In practice, non-critical machines may only require e.g. two

radial measurements to be taken on a regular basis. If

vibration increases, measure the other locations as well.

Most machine manufacturers' vibration limits are based

upon readings taken directly at the bearing housing.

Practical limitations, however, often prevent access to this

ideal location so that points some distance away must be

chosen. Generally, though, measurements should still be

taken as close as possible to the bearings on the stiffest

possible section of available machine casing. Of course,

cantilevered or poorly-supported housing sections are par-

ticularly resonance-prone

and therefore unsuitable as

measurement locations.

Once the exact measure-

ment locations have been

determined, be sure to

mark them clearly so that

all subsequent measure-

ments can be taken at the

same points. This is espe-

cially important as vibra-

tion readings can vary

greatly if the probe location

is moved even slightly.

E

NT

E

N

T

M

Vibration measurements

Radial (vertically)

Axial

Radial

(horizontally)

Loading...

Loading...