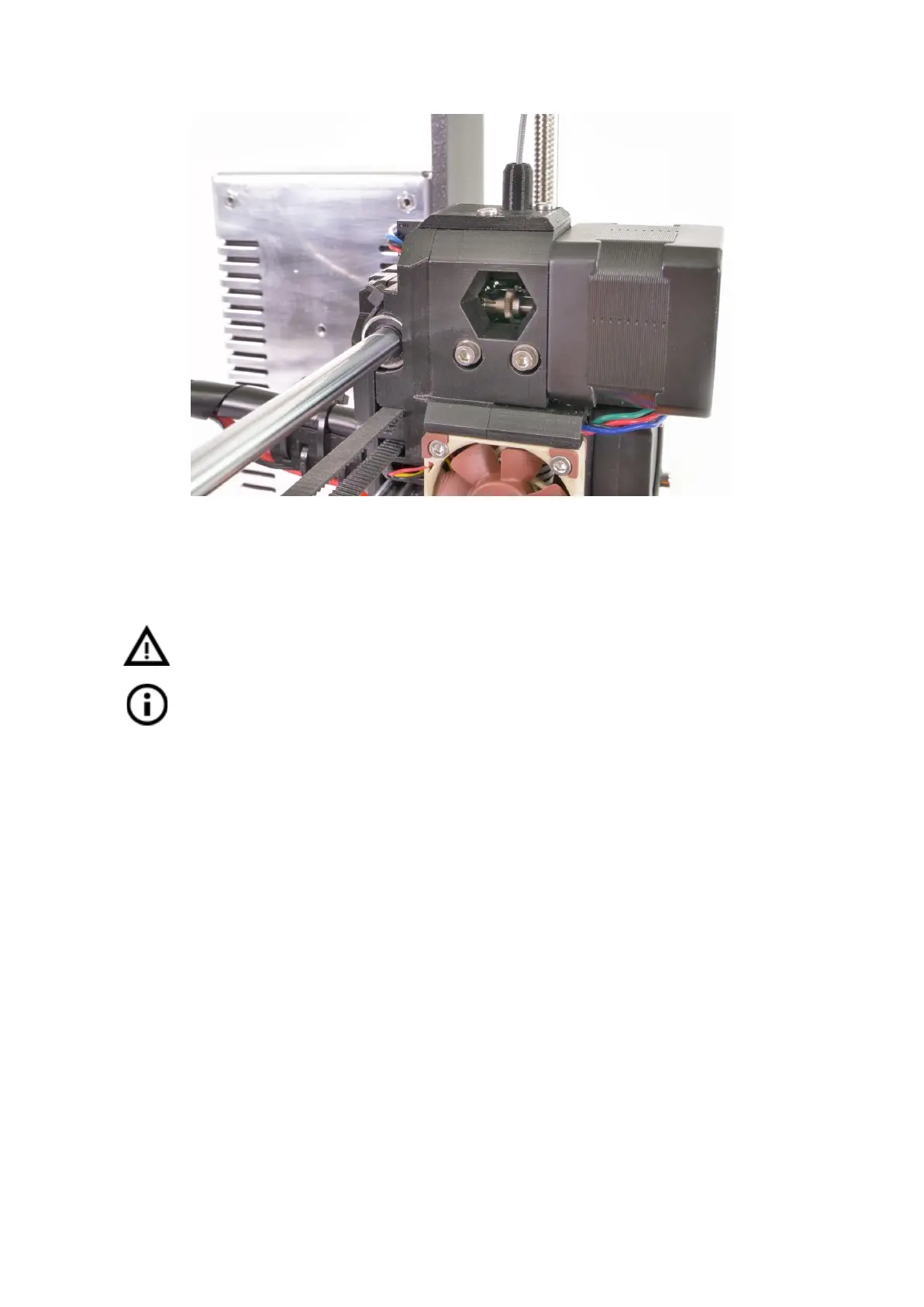

Pict.

39

-

Cleaning

the

extruder

-

you

can

see

the

hobbed

pulley

through

the

service

hole

12.5 Nozzle cleaning

Do not touch the nozzle during these procedures as it is preheated and you may

burn yourself!

To make cleaning easier, move the extruder head up. On the LCD menu go to

Settings -> Move axis -> Move Z axis. As you will be operating with the hotend.

Use

a

wire

brush

to

clean

the

nozzle

from

the

outside.

Heat

the

nozzle

before

you

do

so.

Filament is pouring out a little

If the filament doesn’t go through the extruder smoothly and only a small volume is coming

out, first check if the extruder fan is working properly and that the temperature is set correctly

(PLA 210 °C; ABS 255 °C, HIPS 220 °C, PET 240 °C). Also check that the filament was

correctly loaded into the extruder.

If that is not the case. Follow the instructions below:

1. Heat the nozzle according to the filament you want to print from. Load the filament

and push a bundled acupuncture needle (0,3-0,35 mm) into the nozzle from below

- between 1 and 2 cm deep.

2. Choose Load filament option from the LCD menu and check if filament is extruded

properly.

3. Push the acupuncture needle into the nozzle again and repeat these steps a few

times more. When the filament is extruded properly, the nozzle is clear.

None of the filament is going through the nozzle

If none of the filament is going through, then most likely, your hotend got clogged. In order to

fully clear it, please follow these instructions:

63

Loading...

Loading...