SECTION 9 - MAINTENANCE

QUANTECH

153

FORM QTC4-NM1

ISSUE DATE: 4/2/2018

9

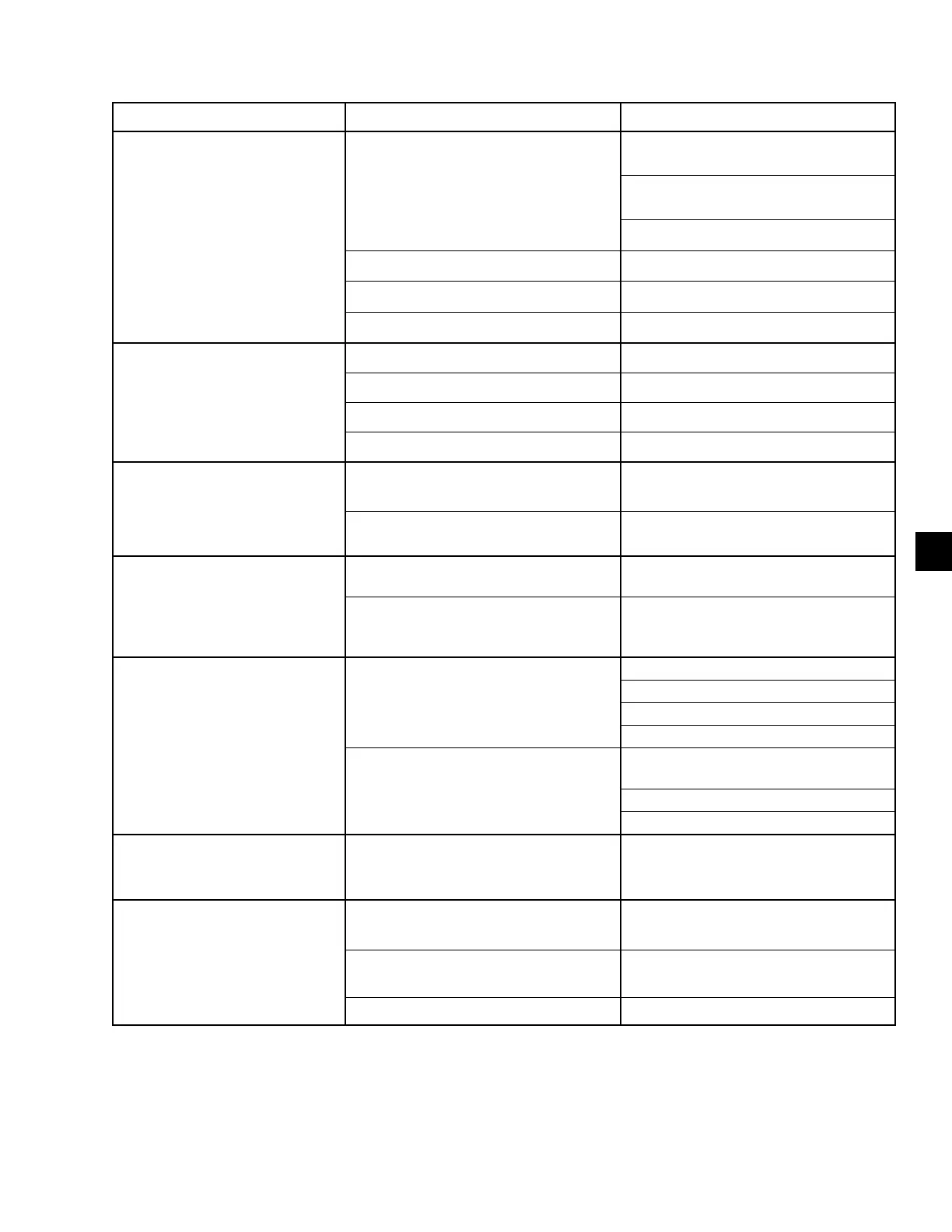

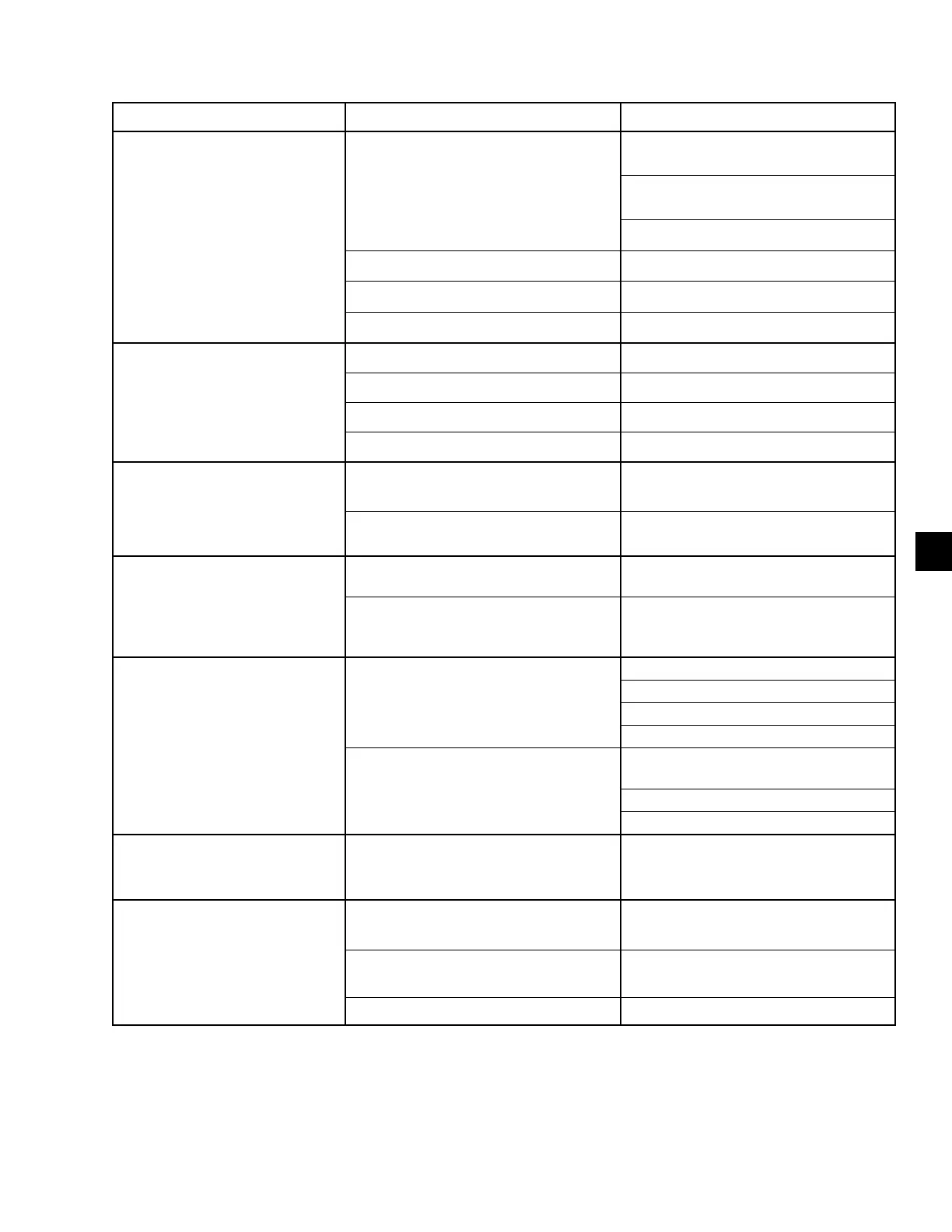

TABLE 25 - TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE ACTION

NO DISPLAY ON CONTROL

PANEL UNIT WILL NOT RUN

Supply to the Panel is missing.

High Voltage to the Chiller is missing.

Check 1FU, 2FU, 4FU, 5FU 17FU, or

19FU.

Check 2T or 10T Transformer.

Line Fuse is blown. Check Fuses.

Chiller Control Board is defective. Replace Chiller Control Board.

Display Board defective. Replace Display Board.

LINE FUSE BLOWS

SCR Diode Module is defective. Check SCR/Diode Module.

IBGT Module is defective. Check IBGT Module.

VSD Logic Board is defective. Replace VSD Logic Board.

SCR Trigger Board is defective. Replace SCR Trigger Board.

CHILLER FAULT:

LOW AMBIENT TEMPERATURE

Ambient temperature is lower than

the programmed operating limit.

Check the programmed cutout and

determine if it is programmed correctly.

Ambient Sensor is defective.

Check the panel against the thermometer

reading of ambient temperature.

CHILLER FAULT:

HIGH AMBIENT TEMPERATURE

Ambient Temperature is above the

maximum operating limit.

Check outside air temperature.

Ambient Sensor is defective.

Check the Panel Display against

Thermometer reading of Ambient

Temperature at the sensor.

CHILLER FAULT:

LOW LEAVING CHILLED LIQUID

Leaving chilled liquid temperature drops

faster than the unit can unload.

Check for restricted ow.

Check for rapid ow changes.

Water loop is too small.

Flow is below minimum for chiller.

Chilled Water Sensor is defective.

Check Sensor against Temp. Gauge in

water line.

Check Sensor for intermittent operation.

Check Wiring for shorts or opens.

SYSTEM FAULT:

CONTROL VOLTAGE

System Fuse is blown.

Check respective system Fuse 20FU

or 21FU.

SYSTEM FAULT:

HIGH OIL TEMPERATURE

Oil Temperature Sensor is defective.

Check Sensor with infrared to determine if

reading is reasonable.

Condenser Fans NOT operating or

running backwards.

Check Fans.

Coils dirty. Check and clean Coils.

NOTE: Always remove power to the chiller and assure the DC Bus voltage has bled off.

Loading...

Loading...