QUANTECH

30

SECTION 3 - RIGGING, HANDLING AND STORAGE

FORM QTC4-NM1

ISSUE DATE: 4/2/2018

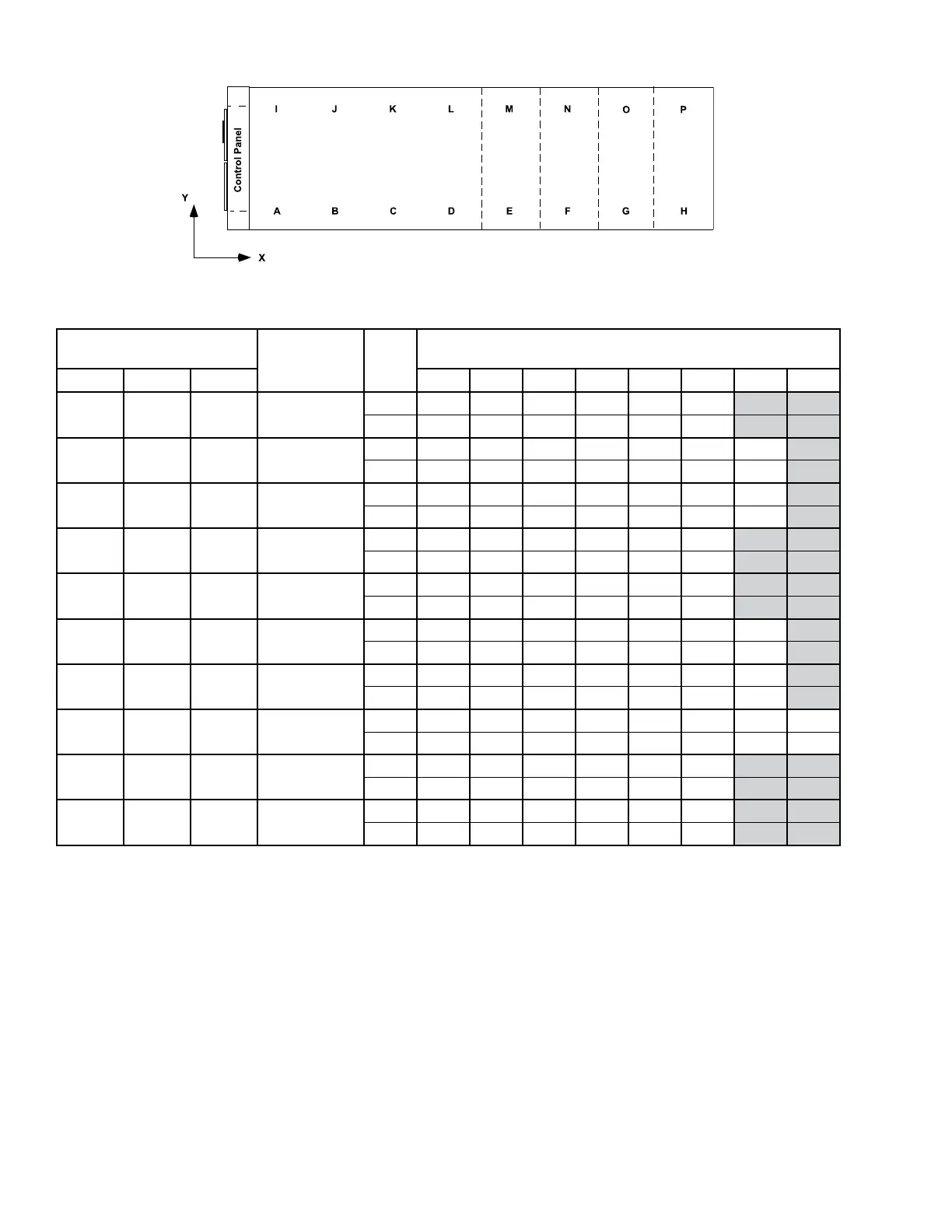

TABLE 1 - UNIT RIGGING (CONT'D)

LD18582

QTC4 MODEL

DESCRIPTION UNITS

RIGGING HOLES

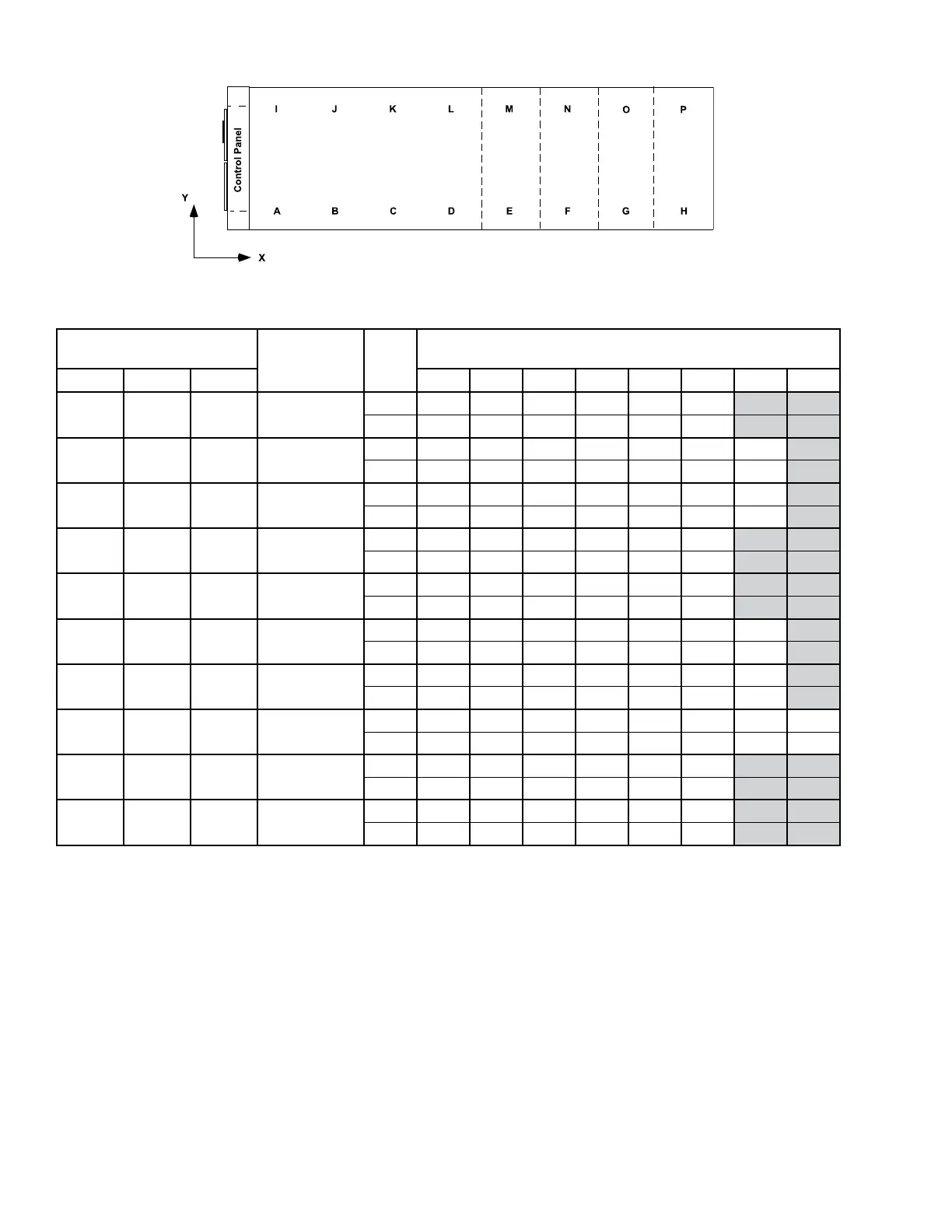

MODEL COND EVAP A B C D E F G H

300 H C

Rigging Hole

Location

inches 12 73 161 254 306 391

mm 314 1845 4092 6443 7763 9941

310 P E

Rigging Hole

Location

inches 12 73 121 179 243 296 391

mm 314 1845 3072 4549 6169 7508 9942

315 P E

Rigging Hole

Location

inches 12 73 121 179 243 353 435

mm 314 1845 3072 4549 6169 8962 11059

320 S E

Rigging Hole

Location

inches 12 73 121 181 243 347

mm 314 1845 3073 4601 6169 8825

330 S C

Rigging Hole

Location

inches 12 73 163 254 306 391

mm 314 1845 4144 6443 7765 9942

340 S E

Rigging Hole

Location

inches 12 73 121 181 243 296 391

mm 314 1845 3073 4602 6170 7511 9942

340 H E

Rigging Hole

Location

inches 12 73 121 181 243 353 435

mm 314 1845 3073 4602 6170 8961 11059

370 P J

Rigging Hole

Location

inches 12 73 181 238 302 392 434 501

mm 314 1845 4602 6039 7662 9957 11024 12725

370 S F

Rigging Hole

Location

inches 12 73 181 238 302 435

mm 314 1845 4602 6039 7662 11059

370 H J

Rigging Hole

Location

inches 12 73 181 238 302 435

mm 314 1845 4602 6039 7662 11059

NOTE: Rigging and lifting the unit must be done by a professional rigger safely, as discussed in this section. The rigger should locate the center

of gravity through trial lifts to account for possible variations in unit conguration. Contact your nearest Quantech Sales Ofce for weight data.

Loading...

Loading...