INTRODUCTION

APPENDIX B

TRACK

FORMATTING

The ProDrive disk drives are shipped from the factory as "hard sectored" drives. That is, all physical

sector addresses are written on the disks before the drives are shipped. Sector size and number

of

sectors per

track are, therefore, not user selectable. The SCSI peripheral bus uses "logical blocks" as the means

of

transferring data to and from the disk drives. This appendix describes the physical fonnat

of

the ProDrive

as it is defined

at

the factory prior to shipment.

TRACK FORMAT

The ProDrive Series drives use information on the disks to define the physical sectors. Each sector is

capable

of

holding 512 bytes

of

data (plus 6 bytes for ECC). Tracks 0 to 589 contain 35 sectors; tracks

590

.to

833 contain 28 sectors. One sector is used as a spare for every 6 tracks for defect management.

(See Appendix C.) For the

ProDrive 40S (2 disks, 3 heads), the first 590 cylinders have

105

physical

sectors available and the last 243 cylinders have 84 sectors. The

ProDrive

80S

(3

disks, 6 heads) has 210

and 168 sectors available. These sectors are sequentially numbered beginning with cylinder 0, head 0

through cylinder 833, head 5 in the case

of

the ProDrive 80S;

or

cylinder 833, head 2 in the case

of

the

ProDrive 40S. Therefore, the ProDrive 40S contains 82,029 sequentially-numbered sectors, and the

ProDrive 80S contains 164,058 sequentially-numbered sectors, each capable

of

storing 512 bytes

of

data.

TRACK AND CYLINDER SKEWING

Since the ProDrive 40S/80S drives are storage subsystems with integrated SCSI controllers. the function

and design

of

the controller can be optimized specifically for the drive. One method

of

optimization

employed by Quantum to improve data throughput is skewing sector addresses. The purpose

of

track and

cylinder skewing is to minimize latency time and thus increase data throughput when data is sequentially

accessed to or from the disk. The two types

of

skewing employed, track and cylinder skewing, are described

below.

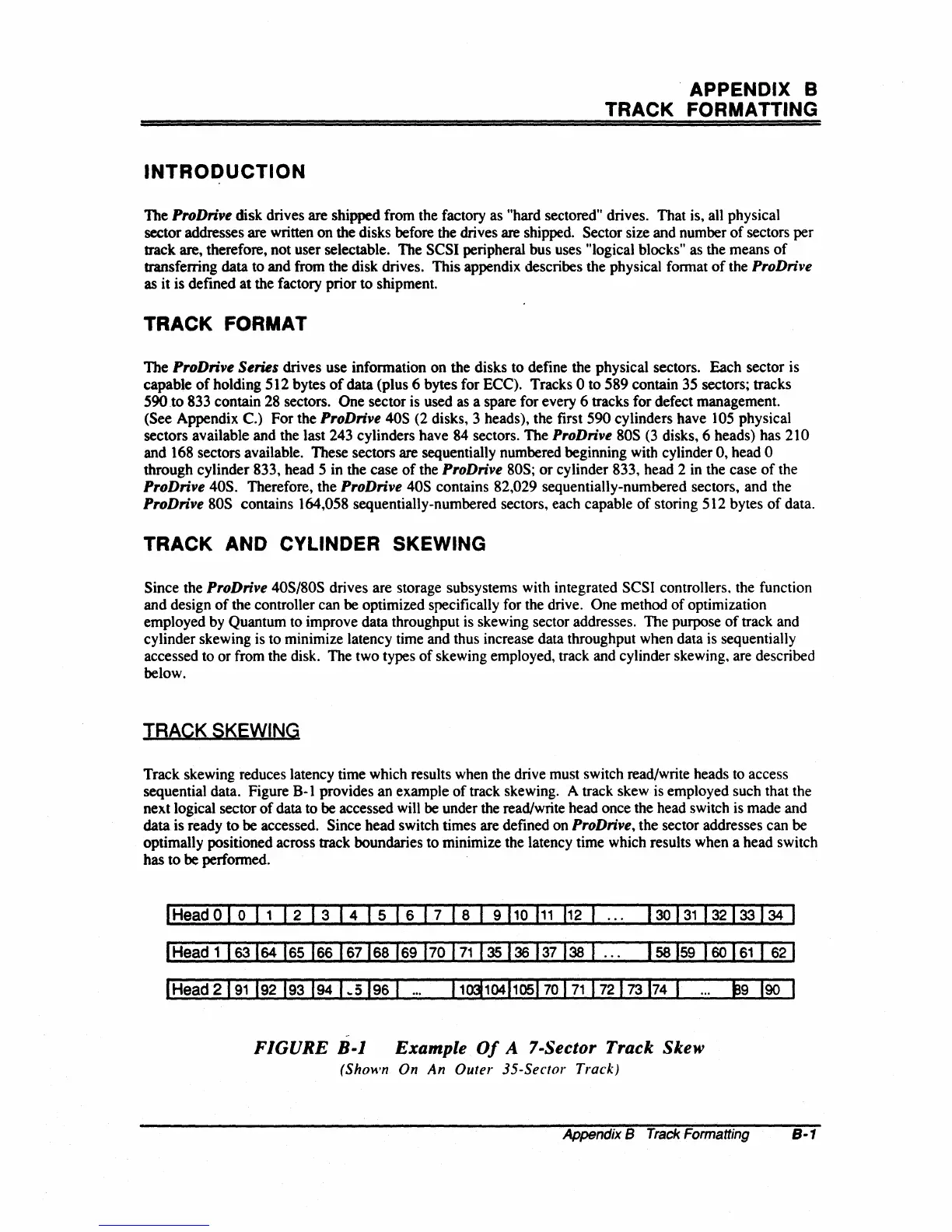

TRACK SKEWING

Track skewing reduces latency time which results when the drive must switch read/write heads to access

sequential data. Figure

B-1

provides an example

of

track skewing. A track skew is employed such that the

next logical sector

of

data to be accessed will

be

under the read/write head once the head switch

is

made and

data is ready to be accessed. Since head switch times are defined on

ProDrive,

the sector addresses can be

optimally positioned across

track boundaries to minimize the latency time which results when a head switch

has to be perfonned.

I

Head

0 1 0

11

1 2 1 3 I 4 I 5 I 6 I 7 I 8 1 9

110

111

112

I

158

159

160

161

1

62

I

I

Head

2191

192 193

194

1

..

5196

I

-

FIGURE

B-1

Example

Of

A 7-Sector Track

Skew

(Shown On

An

Outer

35-Sector Track)

Appendix B

Track

Formatting

8-1

Loading...

Loading...