Section 3 Principles of Operation

3.2

ProDrive

40S/80S DRIVE ELECTRONICS

3.2.1

GENERAL DESCRIPTION

All drive electronics, including SCSI controller functions, are contained on one Printed Circuit Board

Assembly (PCBA). This is accomplished through advanced circuit design and the use

of

miniature surface-

mounted devices and proprietary

VLSI components. The only electrical components not contained on the

PCBA are the preamplifier chip for the read/write circuitry, and the electronic circuitry for the optical

encoder photocells and infared LED; these are located under the drive cover. The preamplifier is mounted as

close to the read/write heads as possible to improve the signal-to-noise ratio. The following paragraphs

provide operation details for major functional

circui~s

within the drive.

3.2.2

HEAD POSITIONING SYSTEM

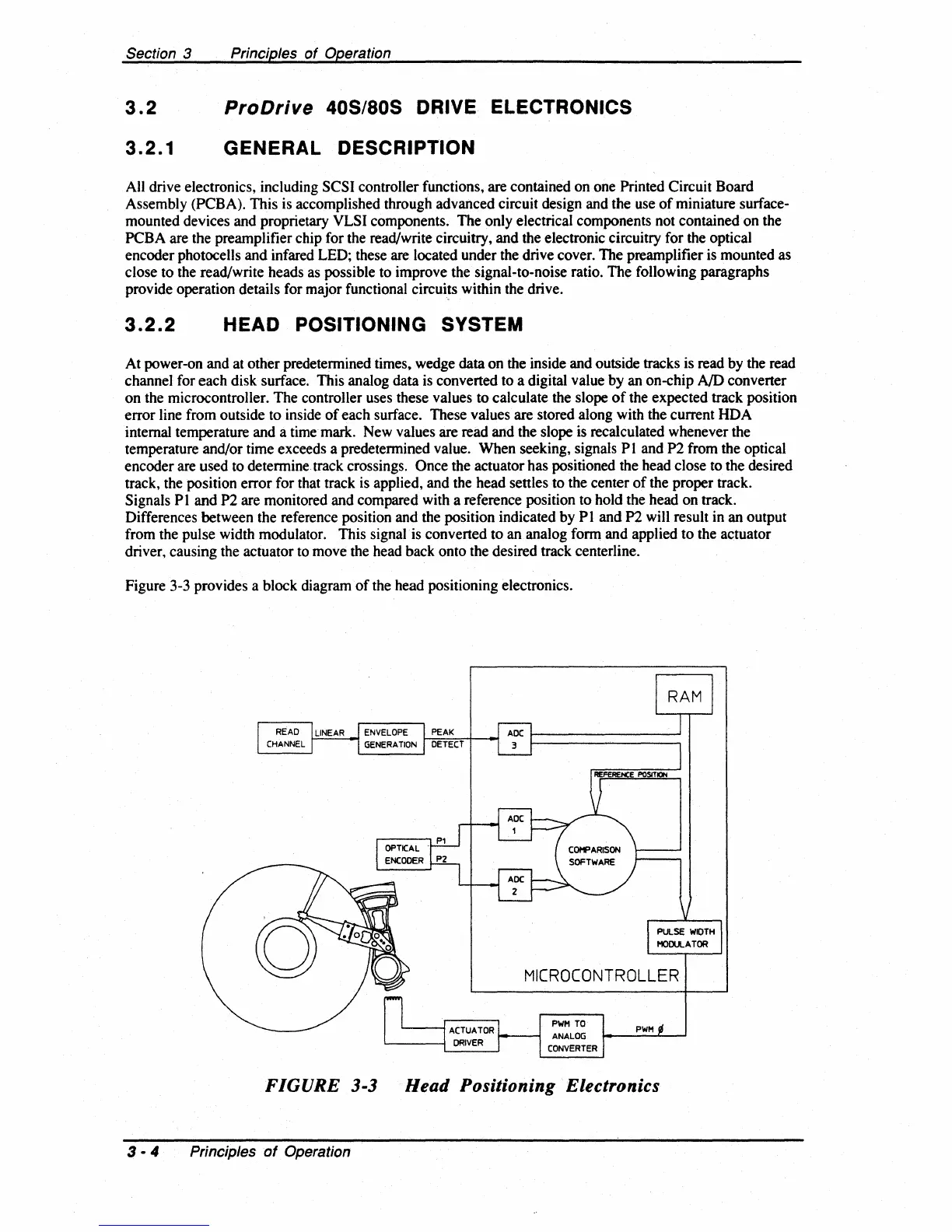

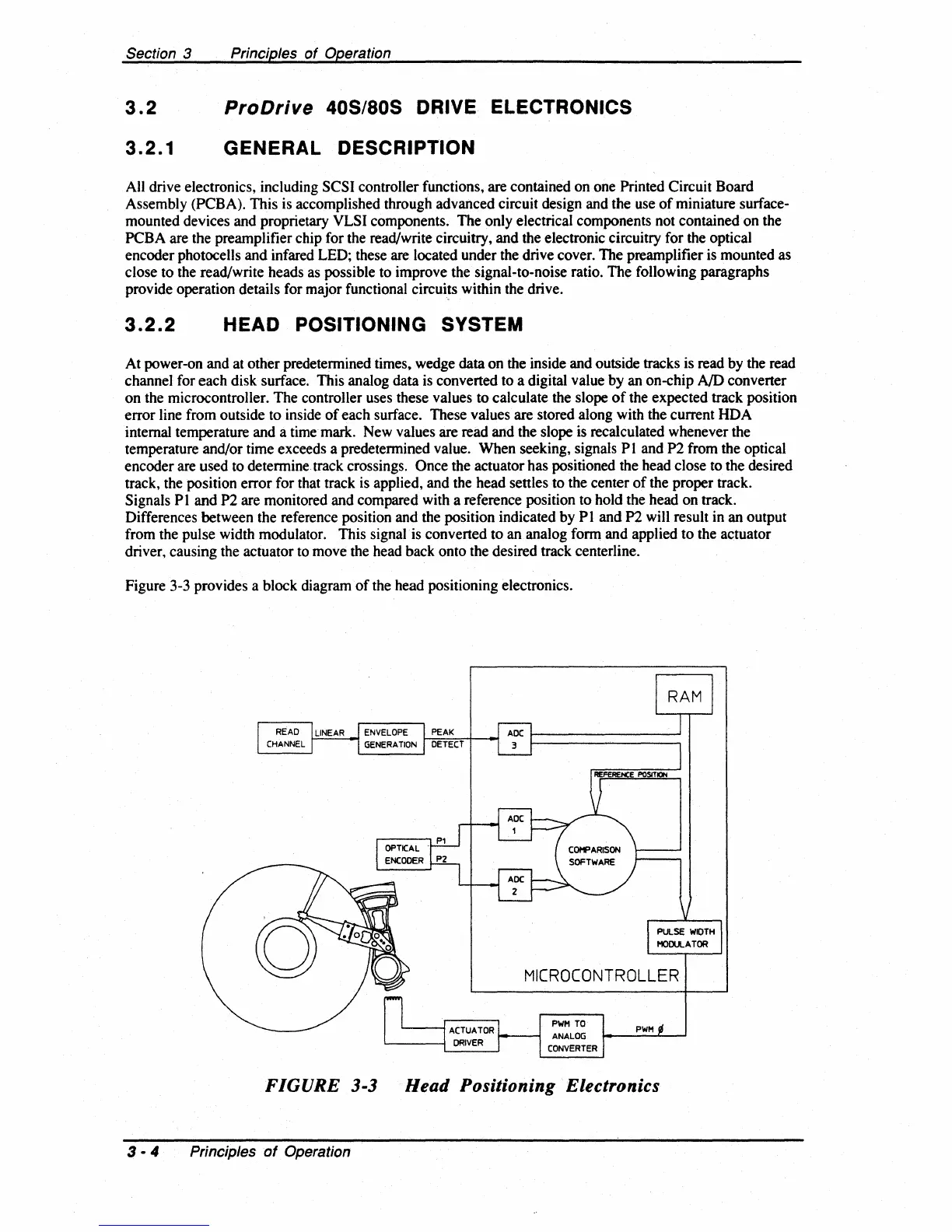

At power-on and at other predetermined times, wedge data on the inside and outside tracks is read by the read

channel for each disk surface. This analog data is converted to a digital value by an on-chip

AID

converter

on the microcontroller. The controller uses these values to calculate the slope

of

the expected track position

error line from outside to inside

of

each surface. These values are stored along with the current HDA

internal temperature and a time mark. New values are read and the slope

is

recalculated whenever the

temperature and/or time exceeds a predetermined value. When seeking, signals P I and P2 from the optical

encoder are used to determine track crossings.

Once the actuator has positioned the head close to the desired

track, the position error for that track is applied, and the head settles to the center

of

the proper track.

Signals

PI

and P2 are monitored and compared with a reference position to hold the head on track.

Differences between the reference position and the position indicated by

PI

and P2 will result in an output

from the pulse width modulator. This signal is converted to an analog form and applied to the actuator

driver, causing the actuator to move the head back onto the desired track centerline.

Figure 3-3 provides a block diagram

of

the head positioning electronics.

MICROCONTROLLER

FIGURE

3-3

Head Positioning Electronics

3 • 4 PrinCiples

of

Operation

Loading...

Loading...