Section 2

Installation and Operation

2.1.3

MOUNTING

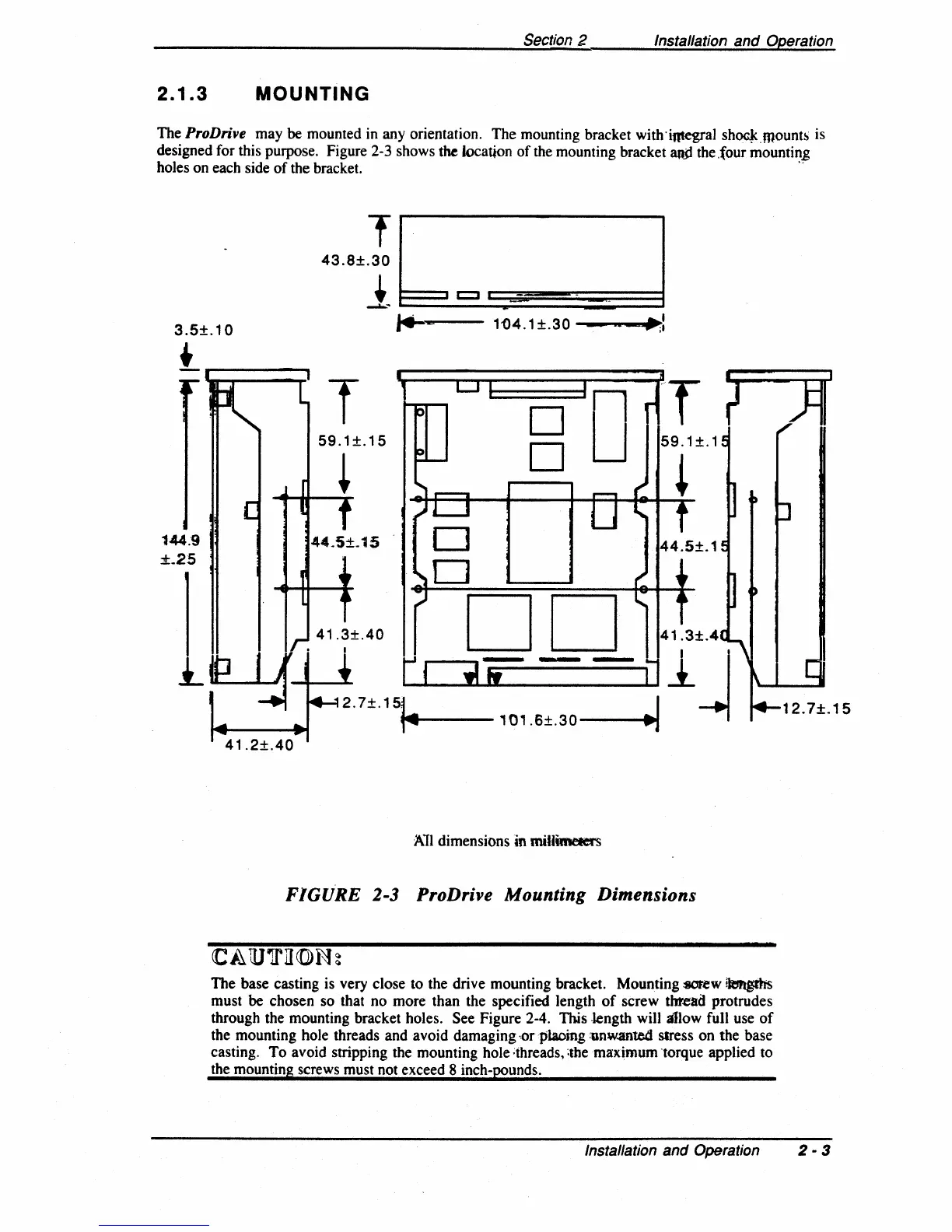

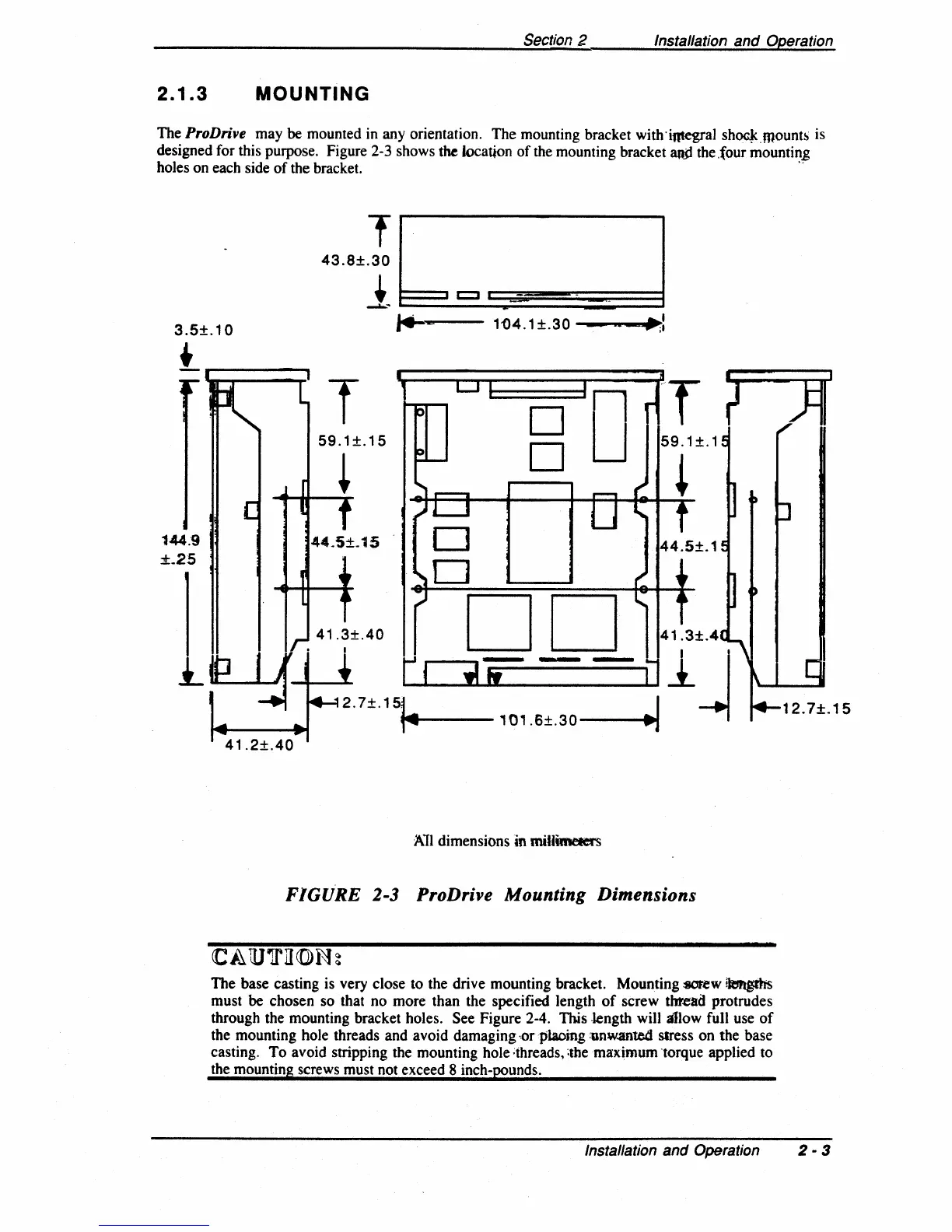

The ProDrive may be mounted in any orientation. The mounting bracket with'integral

shoc.J<.mo

unts

is

designed for this purpose. Figure 2-3 shows

the location

of

the mounting bracket

ami

the .four mountin,g

holes on each side

of

the bracket.

'.

T

D

o

1'04.1

±.30

---,..

••

;:

D

D

DD

2.7±.1~

'01'6±'30

__

~

...

ll

~

All dimensions

in

millimeters

FIGURE 2-3 ProDrive Mounting Dimensions

The base casting is very close to the drive mounting bracket. Mounting

:9OF.ew

!kmg:ths

must be chosen so that

no

more than the specified length

of

screw

thread

protrudes

through the mounting bracket holes.

See Figure 2-4. This .length will allow full use

of

the mounting hole threads and avoid damaging ,orplaoing

:unw.ante.d

stress on the base

casting.

To

avoid stripping the mounting hole ;ihreads,

;themaximum

'torque applied to

the mounting screws must not exceed 8 inch-pounds.

Installation and Operation 2 • 3

Loading...

Loading...