Section 3

Principles

of

Operation

3.1.6

AUTOMATIC ACTUATOR LOCK

The ProDri,'e uses a dedicated landing zone to ensure data integrity and prevent damage during shipment.

It also uses AIRLOCK@. Quantum's patented means

of

locking the headstack in the landing zone. The

AIRLOCK consists

of

an airvane mounted close to the edge

of

the disk stack with an

ann

that intersects the

actuator to hold the headstack in the landing zone whenever the disk is not rotating. As DC power is

applied to the motor and the disk stack starts rotating, an airflow is generated around the disk. As airflow

increases with disk rotation, the airvane and its

ann

rotate. enabling the headstack to move freely out

of

the

landing zone. When DC power is removed from the motor, an electronic return mechanism automatically

pulls the actuator into the landing zone so the

AIRLOCK can hold it

in

place.

3.1.7

AIR FILTRATION

The

ProDri~e

Series drives are Winchester type drives and. as such, the heads fly very close to'the media

surface.

The

nominal flying height is 8 microinches - more than 2500 times smaller than the period

at

the

end

of

this sentence.

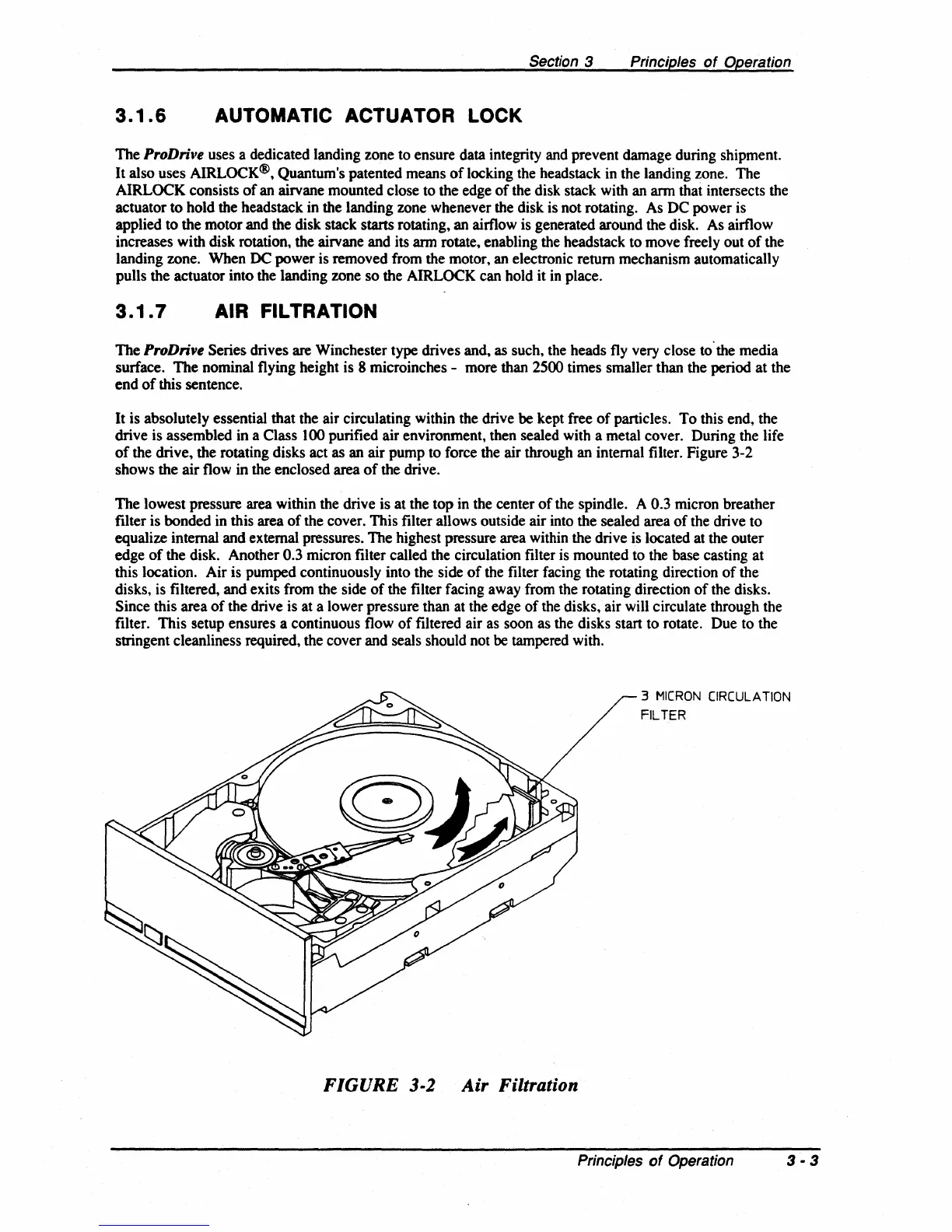

It is absolutely essential that the air circulating within the drive

be kept free

of

particles.

To

this end, the

drive is assembled in a Class 100 purified air environment, then sealed with a metal cover. During the life

of

the drive. the rotating disks act as an air pump to force the air through an internal filter. Figure 3-2

shows the air flow in the enclosed area

of

the drive.

The lowest pressure area within the drive is at the top in the center

of

the spindle. A 0.3 micron breather

filter is bonded in this area

of

the cover. This filter allows outside air into the sealed area

of

the drive to

equalize internal and external pressures. The highest pressure area within the drive is located at the outer

edge

of

the disk. Another 0.3 micron filter called the circulation filter is mounted to the base casting at

this location. Air is pumped continuously into the side

of

the filter facing the rotating direction

of

the

disks, is filtered, and exits from the side

of

the filter facing away from the rotating direction

of

the disks.

Since this area

of

the drive is at a lower pressure than at the edge

of

the disks, air will circulate through the

filter. This setup ensures a continuous flow

of

filtered air as soon as the disks start to rotate. Due to the

stringent cleanliness required, the cover and seals should not

be tampered with.

FIGURE

3·2

Air

Filtration

3

MICRON

CIRCULATION

FILTER

Principles

of

Operation 3 • 3

Loading...

Loading...